AllTrades

Member

Hi Guys (& Gals, sorry, that was meant in a none-gender way!)

New here and to the general world of 'hands on' semi-serious woodworking.

After a little miss-hap with a hot pan and the laminated worktop, I decided to put a chopping board into it!

The perfect excuse to add a router to my tool collection. Went to B&Q and settled on a MacAllister 1500W plunge Router, middle of the road I thought for £80. Then after being bamboozled with the myriad of bits, I settled on a set from Trend with a decent sized 1/2" straight bit Incl.

Got a granite 400x300 board from argos, thought simple mark out, set the depth and off I go - 1 hr tops Sorted!!!

Ok stop smirking

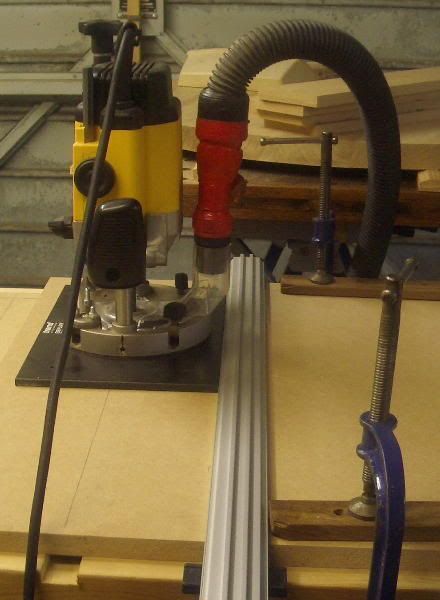

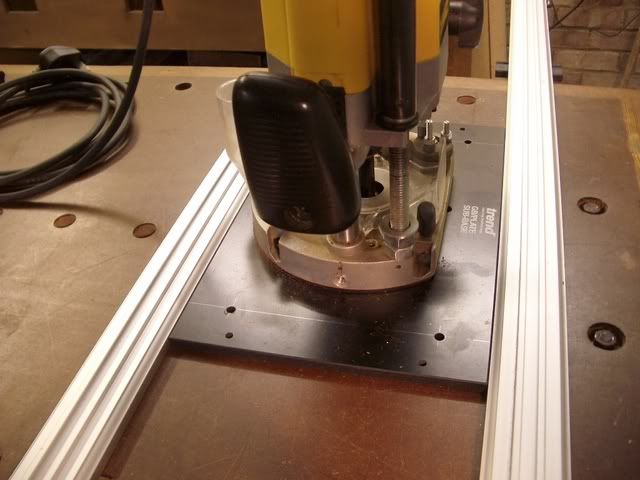

Thankfully I had a spare section of worktop and against my usual judgement decided to practice first. WOW, these things can really move. Decided I need a rail of some kind - impossible to do this freehand, especially as I need to make a couple of passes (although only taking out 14mm, found it dragged a bit at full depth straight off!!).

Now to the real problem....how to fix a guide rail to the worktop without damaging what was going to remain!

Started out by making rail with stop ends that could be screwed into the inside of the area to be routed, turning it around to do each of the four sides and then stepping back for each pass.

Of course I soon found I ran out of waste board to fix to and suffered due to tilting with no support to the back either!! Nearest supports I could find to hand was a 15mm ply rip that kind of did the job once I readjusted the depth setting.

I was convinced I would find a solution to this on line - but nothing obvious on the search engines - lots of clamping systems, jigs and templates but all PRE-installation :?:

I called a supplier in Somerset who only dealt with Trend, whilst he couldn't offer a solution also thought it must be a common problem!

Surely, somebody somewhere must have a paralell guide rail system with a cross rail for the router to run up and down AND fix by suction??

After some serious searching I found that FRESTOOL do have a system, but its totally proprietary (Router, Rails, Clips, Adapters & Rails) and too expensive for me!

Anybody offer some advice before I end up having to replace my entire worktops and tiles!!

Oh and a second bit of help pls....The router bit, a Trend 1/2" 19mm dia x 25mm cut burnt out about 3/4 of the way through ripping the centre out. I had a fast speed setting, 5/6 about 22000 I think - is this right or should it be slower for this size? Did 2 passes, but also found that the depth gauge was moving as I was cutting. - Only the gauge, as it was locked off, but upon releasing it for the second pass made it out!!

Sorry to ramble on, promise to keep reply's shorter.

Any advice, tips n tricks or good book recommendations greatly appreciated.

Thanks in advance

Yan

New here and to the general world of 'hands on' semi-serious woodworking.

After a little miss-hap with a hot pan and the laminated worktop, I decided to put a chopping board into it!

The perfect excuse to add a router to my tool collection. Went to B&Q and settled on a MacAllister 1500W plunge Router, middle of the road I thought for £80. Then after being bamboozled with the myriad of bits, I settled on a set from Trend with a decent sized 1/2" straight bit Incl.

Got a granite 400x300 board from argos, thought simple mark out, set the depth and off I go - 1 hr tops Sorted!!!

Ok stop smirking

Thankfully I had a spare section of worktop and against my usual judgement decided to practice first. WOW, these things can really move. Decided I need a rail of some kind - impossible to do this freehand, especially as I need to make a couple of passes (although only taking out 14mm, found it dragged a bit at full depth straight off!!).

Now to the real problem....how to fix a guide rail to the worktop without damaging what was going to remain!

Started out by making rail with stop ends that could be screwed into the inside of the area to be routed, turning it around to do each of the four sides and then stepping back for each pass.

Of course I soon found I ran out of waste board to fix to and suffered due to tilting with no support to the back either!! Nearest supports I could find to hand was a 15mm ply rip that kind of did the job once I readjusted the depth setting.

I was convinced I would find a solution to this on line - but nothing obvious on the search engines - lots of clamping systems, jigs and templates but all PRE-installation :?:

I called a supplier in Somerset who only dealt with Trend, whilst he couldn't offer a solution also thought it must be a common problem!

Surely, somebody somewhere must have a paralell guide rail system with a cross rail for the router to run up and down AND fix by suction??

After some serious searching I found that FRESTOOL do have a system, but its totally proprietary (Router, Rails, Clips, Adapters & Rails) and too expensive for me!

Anybody offer some advice before I end up having to replace my entire worktops and tiles!!

Oh and a second bit of help pls....The router bit, a Trend 1/2" 19mm dia x 25mm cut burnt out about 3/4 of the way through ripping the centre out. I had a fast speed setting, 5/6 about 22000 I think - is this right or should it be slower for this size? Did 2 passes, but also found that the depth gauge was moving as I was cutting. - Only the gauge, as it was locked off, but upon releasing it for the second pass made it out!!

Sorry to ramble on, promise to keep reply's shorter.

Any advice, tips n tricks or good book recommendations greatly appreciated.

Thanks in advance

Yan