PerranOak

Established Member

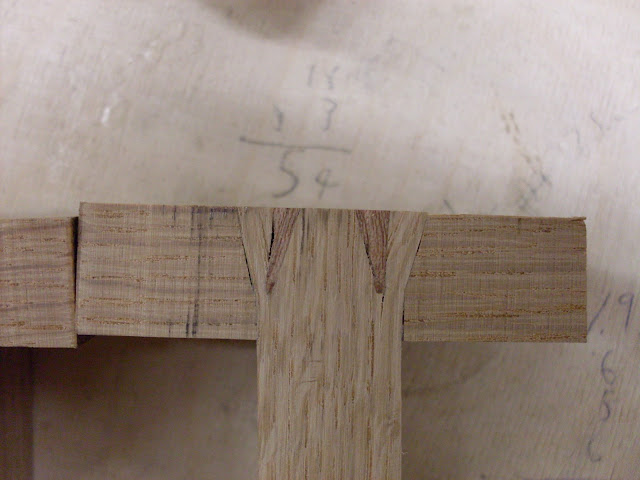

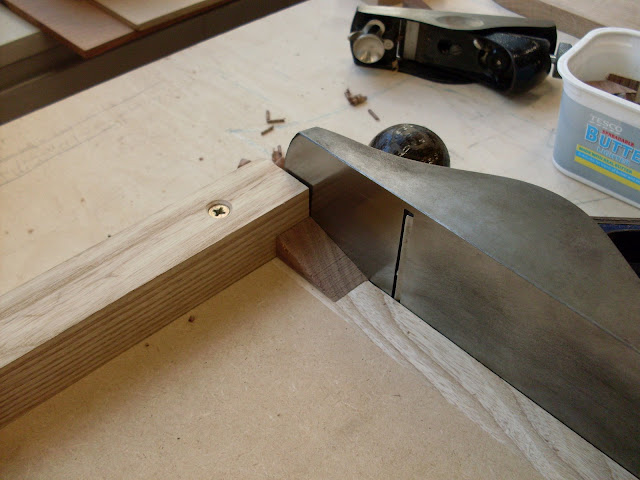

So, I want to do a wedged through tenon. I'm using softwood and the tenon will be about an 18mm "cube" in shape.

I presume that I cut the wedge along the grain so as to "open up" the tenon in a natural way? The grain on the mortice side will be at right angles to the wedge?

Now. Do I have to make the mortice a sort of dove tail shape to take the wedged tenon? How thick (at each end) should the wedge be in this case.

Thank you very much for the guidance.

Cheers.

I presume that I cut the wedge along the grain so as to "open up" the tenon in a natural way? The grain on the mortice side will be at right angles to the wedge?

Now. Do I have to make the mortice a sort of dove tail shape to take the wedged tenon? How thick (at each end) should the wedge be in this case.

Thank you very much for the guidance.

Cheers.