wallace

Established Member

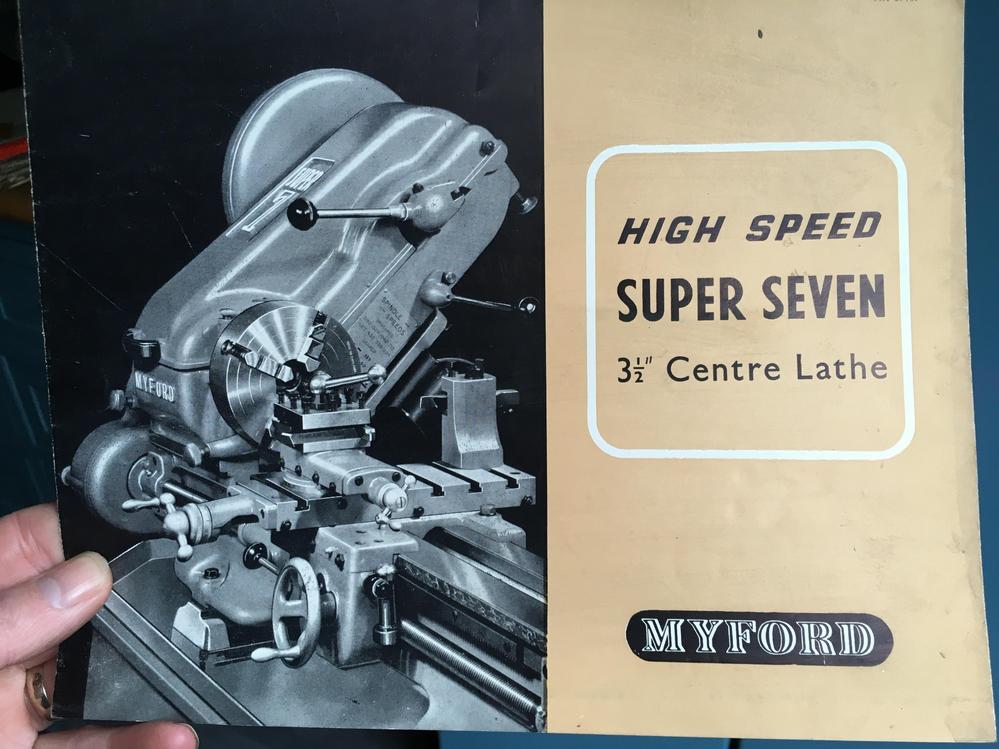

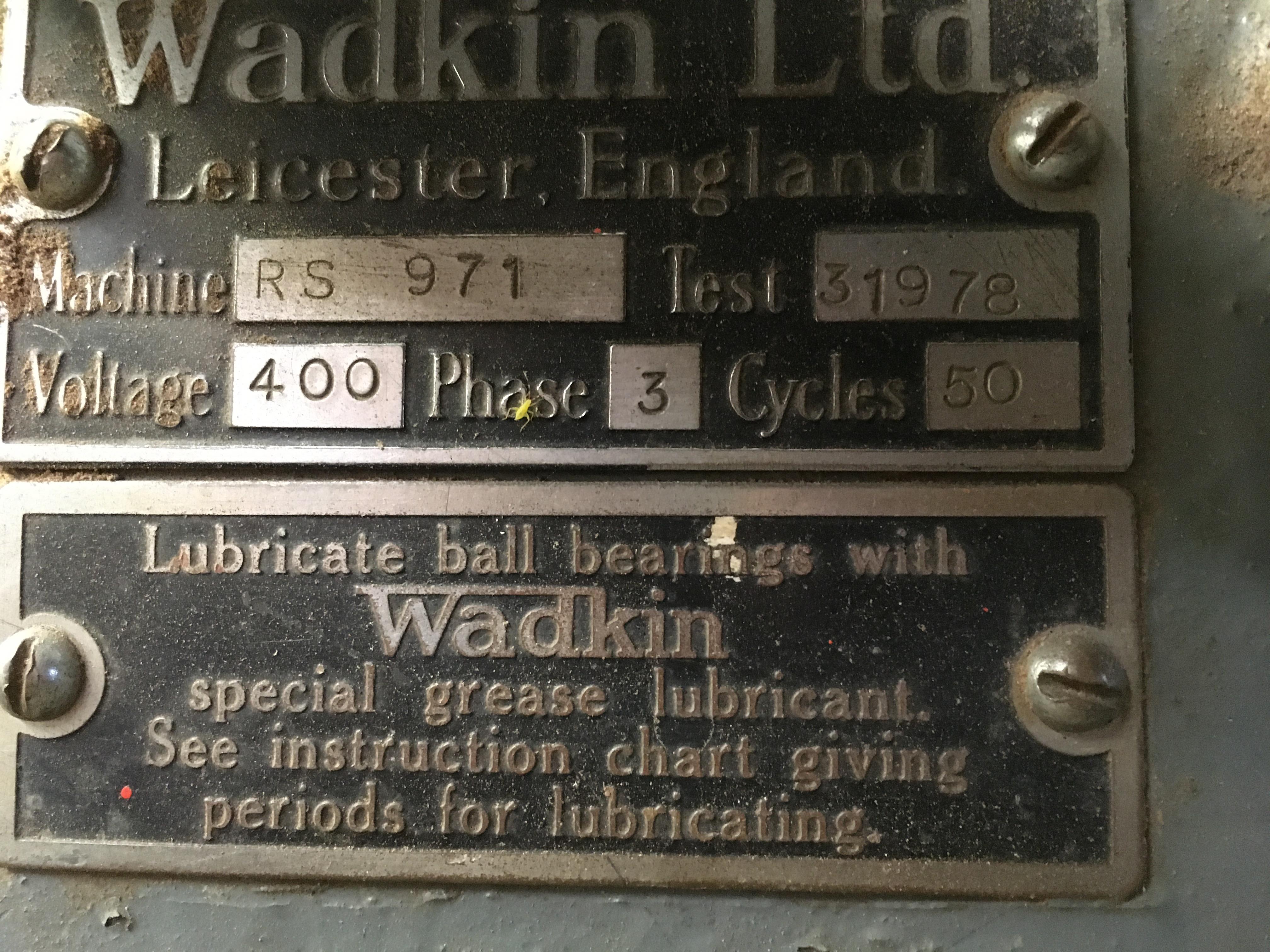

Next on the list is a spontaneous purchase I made off facebook. A rough little RS6". It came from a master wheelwright in devon. Its missing its tool banjo which is going to hard to find. I had one in my stash but used it on another lathe a couple of months ago.

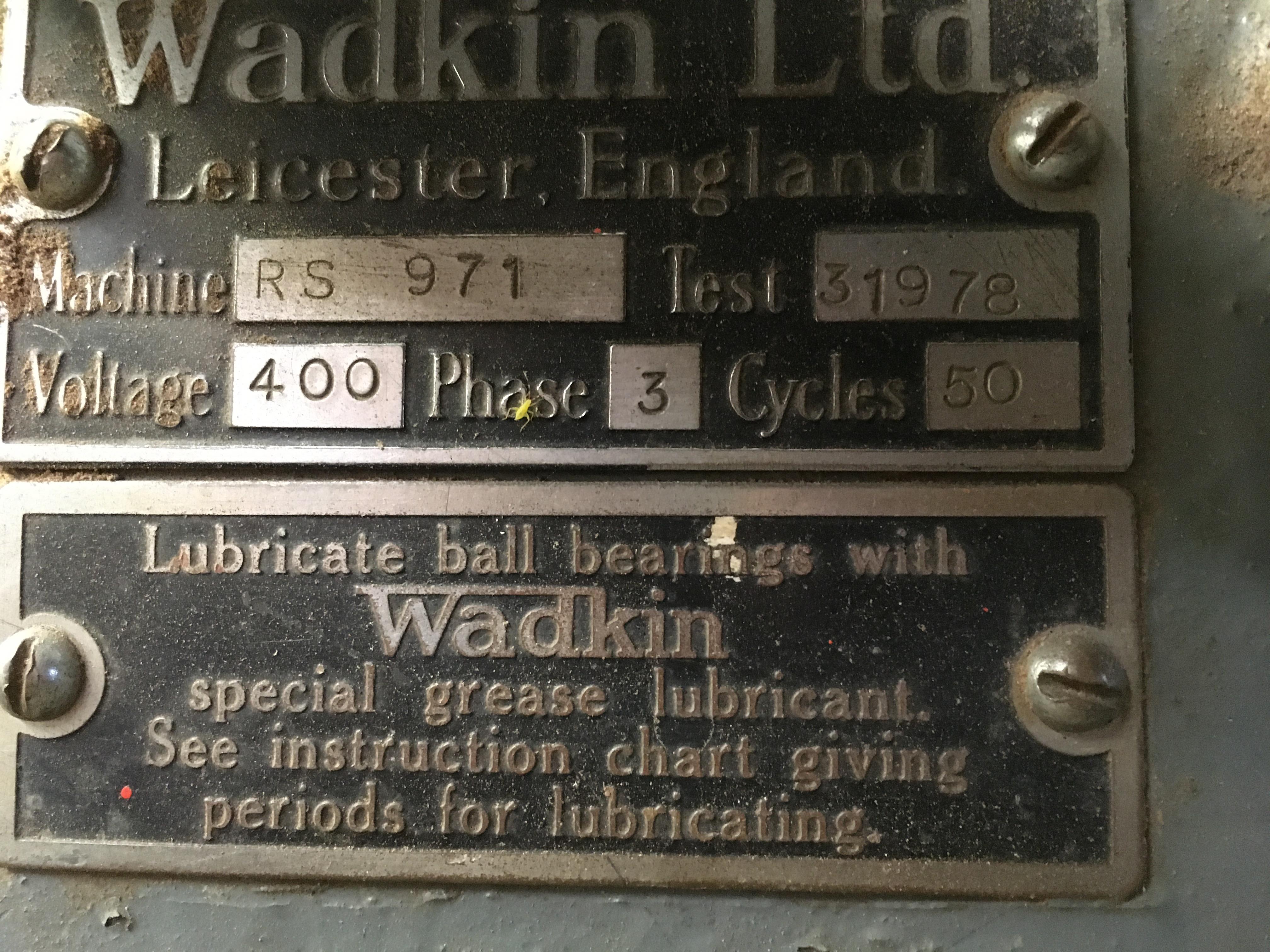

It dates from 1948 which I was surprised at, I thought it would be older due to the window in the main casting.

It was extended a bit

For some reason the pins that hold the motor bracket were not in their right place, and had been hammered on.

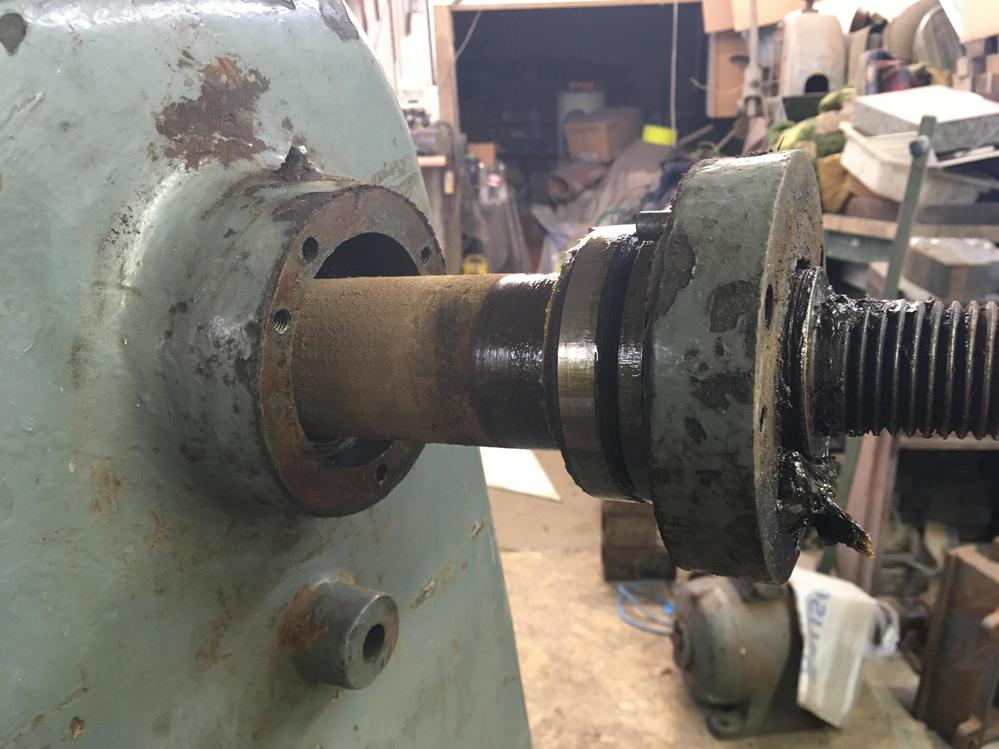

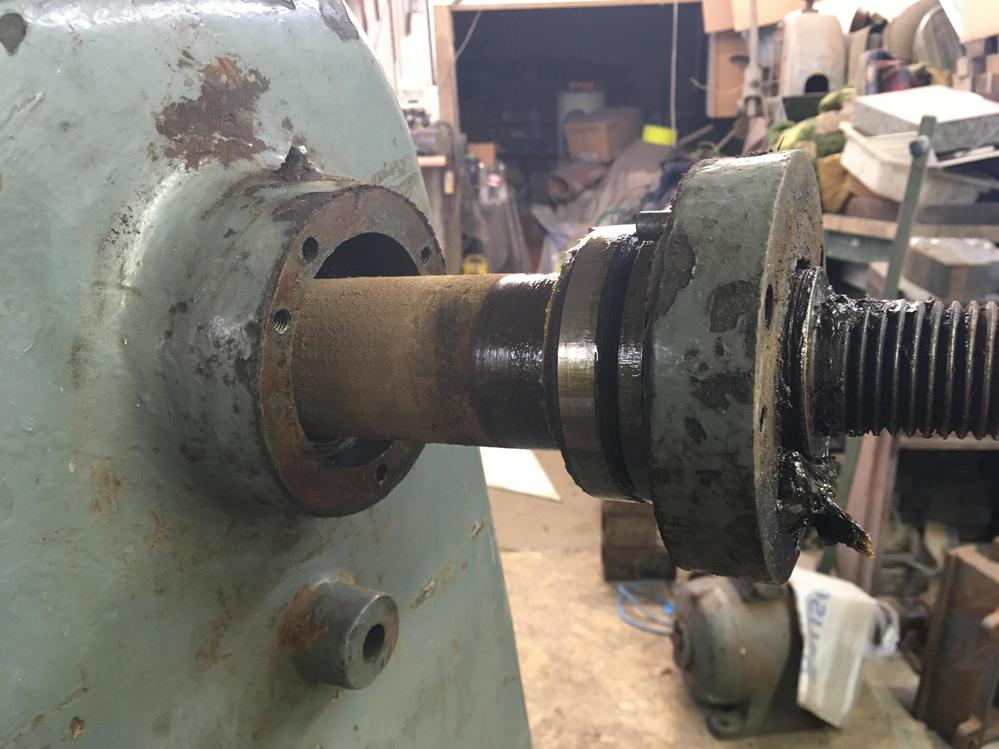

Its supposed to have a collar on this end.

The pins will need some work

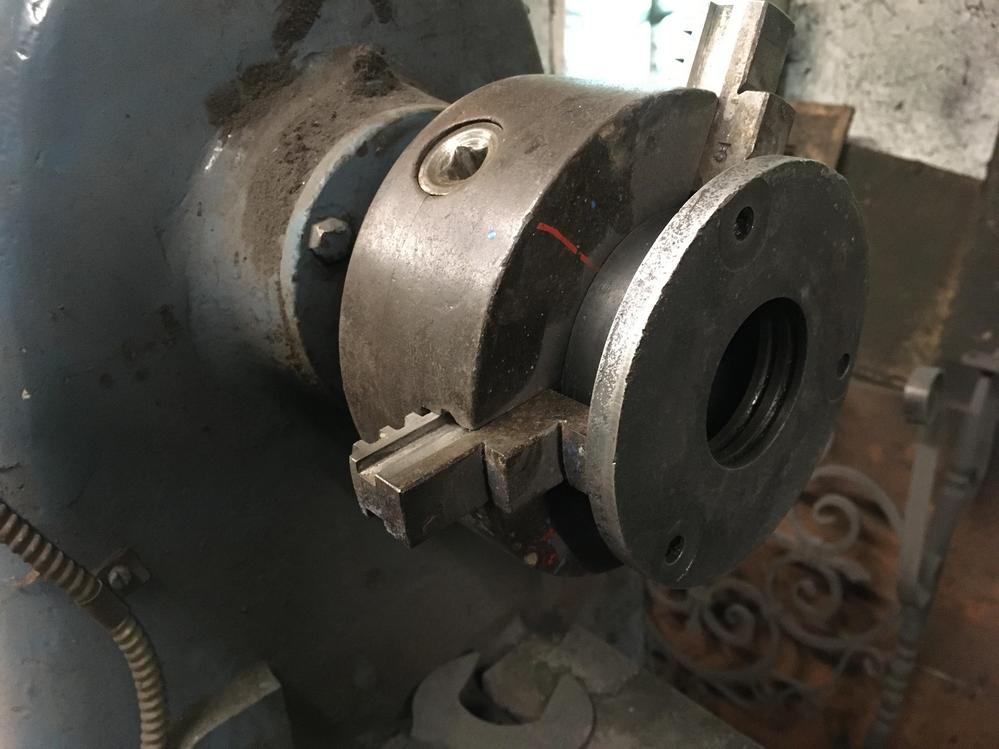

To check the bearings you just grab hold of the spindle and lift it, if theirs any movement it needs bearings. This one does.

A good sign of dodgy bearings is copious amounts of grease as that fixes everything.

This is my home made tool for unscrewing the nut

Then stick a long thing in the hole and hit with a hammer

And voila, the other end cap comes off

The stepped pulleys do not have a grub screw

Then you have to pull the spindle with one hand and catch the stepped pulley with the other.

I don't normally remove all of the existing paint but this is a bit nasty. I had a bad experience with a lathe I did a little while back. I spent along time prepping everything and got a horrible reaction when doing the top coat. This cost about £7O in wasted materials.

To keep dust to a minimum I scraped everything off, it would be nice to have it shot blasted but its not an option. After an hour of scraping my elbows regretted my decision to remove everything. Tennis elbow and repetitive motions don't mix

Then I had a bright idea to use my elcheapo carving machine. Works well but blunts quickly

One of the bargains of the week was these, the company must of listed them incorrectly on ebay, with a 99p starting bid. I paid £1.7O for a box.

Another Aldi special tool.

Time taken 5hrs

It dates from 1948 which I was surprised at, I thought it would be older due to the window in the main casting.

It was extended a bit

For some reason the pins that hold the motor bracket were not in their right place, and had been hammered on.

Its supposed to have a collar on this end.

The pins will need some work

To check the bearings you just grab hold of the spindle and lift it, if theirs any movement it needs bearings. This one does.

A good sign of dodgy bearings is copious amounts of grease as that fixes everything.

This is my home made tool for unscrewing the nut

Then stick a long thing in the hole and hit with a hammer

And voila, the other end cap comes off

The stepped pulleys do not have a grub screw

Then you have to pull the spindle with one hand and catch the stepped pulley with the other.

I don't normally remove all of the existing paint but this is a bit nasty. I had a bad experience with a lathe I did a little while back. I spent along time prepping everything and got a horrible reaction when doing the top coat. This cost about £7O in wasted materials.

To keep dust to a minimum I scraped everything off, it would be nice to have it shot blasted but its not an option. After an hour of scraping my elbows regretted my decision to remove everything. Tennis elbow and repetitive motions don't mix

Then I had a bright idea to use my elcheapo carving machine. Works well but blunts quickly

One of the bargains of the week was these, the company must of listed them incorrectly on ebay, with a 99p starting bid. I paid £1.7O for a box.

Another Aldi special tool.

Time taken 5hrs