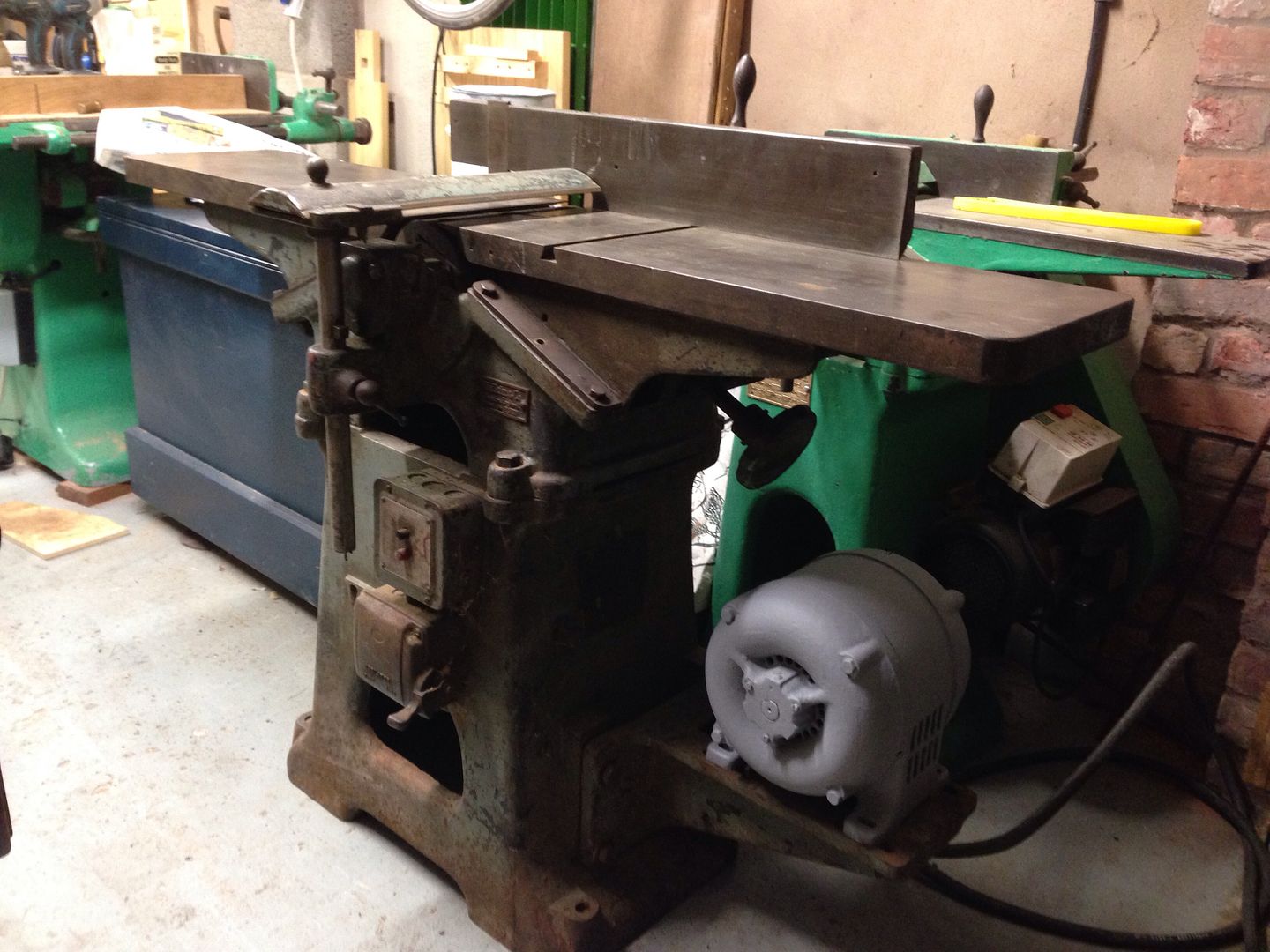

You can't beat old English iron for value for money. I won this Wadkin RB surface planer on ebay for £55.00 last month.

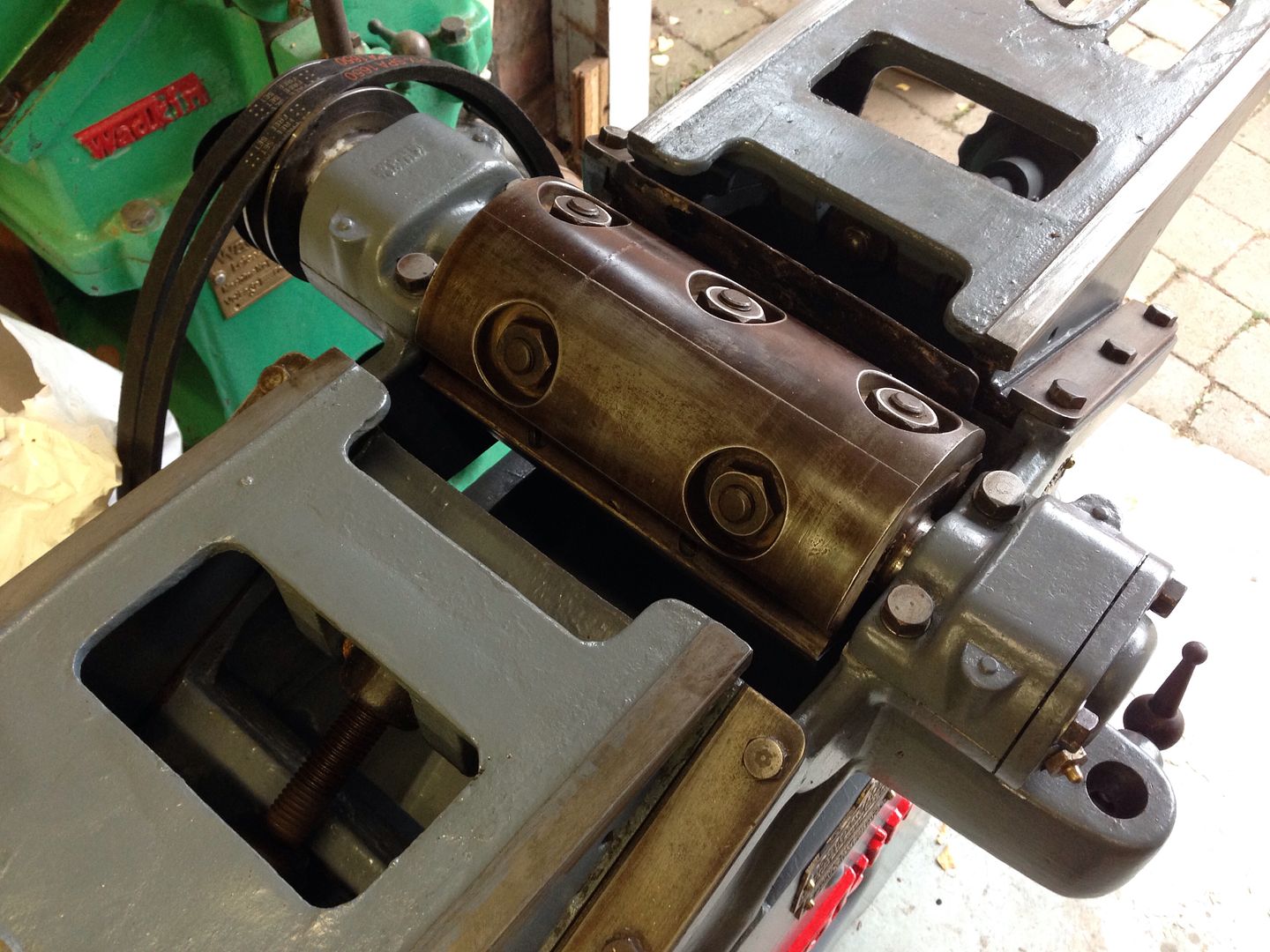

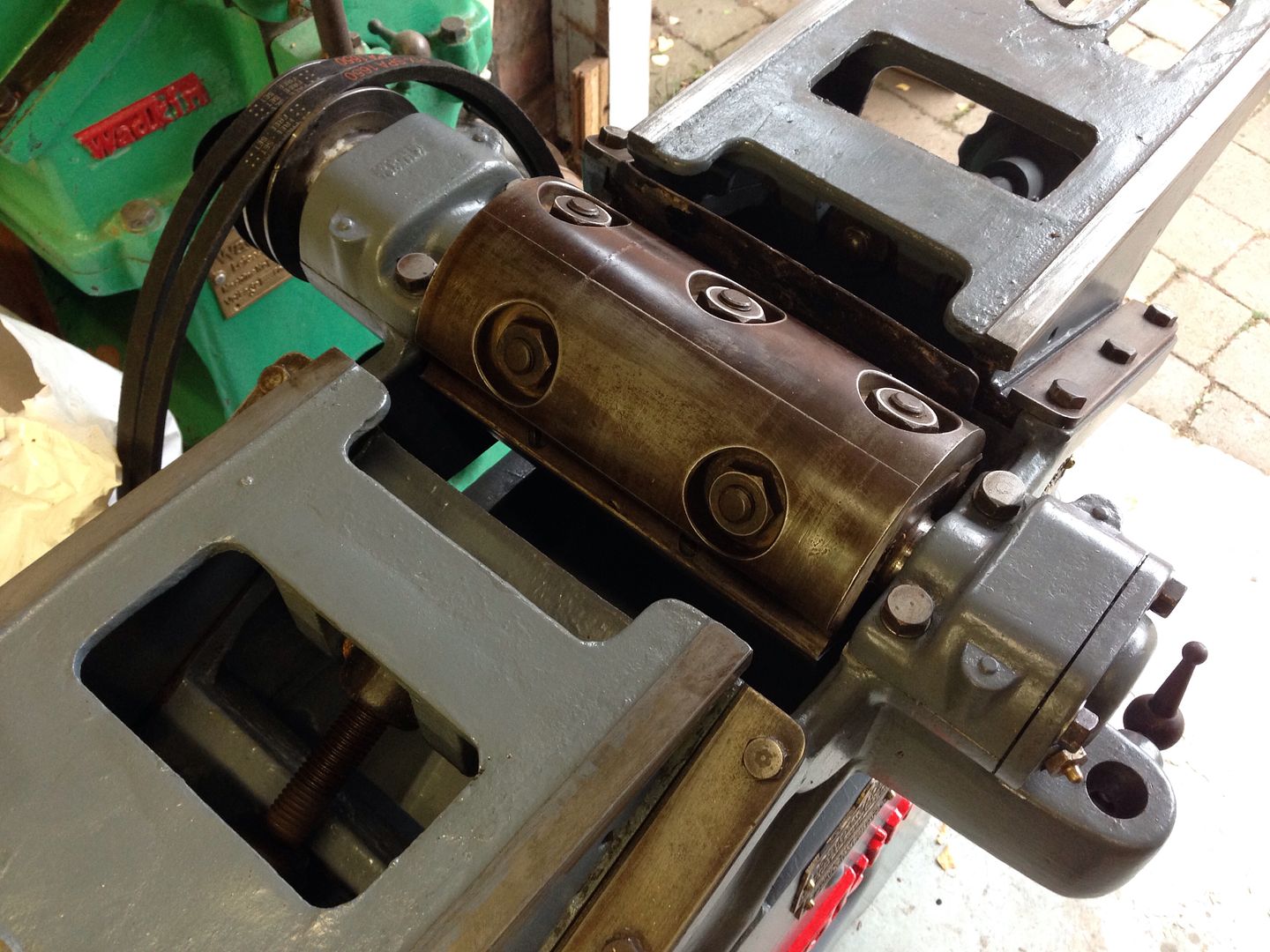

This machine dates from 1937, I don't know when production started however the fence tells me this is one of the earlier machines. It will plane boards up to 9" in width. The segmented head allows moulding cutters to be fitted without disturbing the planing knives, the tables retract to give the required clearance when moulding cutters and allow quick access to the head.

The head is 5" in diameter with a skewed cut, the finish it leaves is impressive.

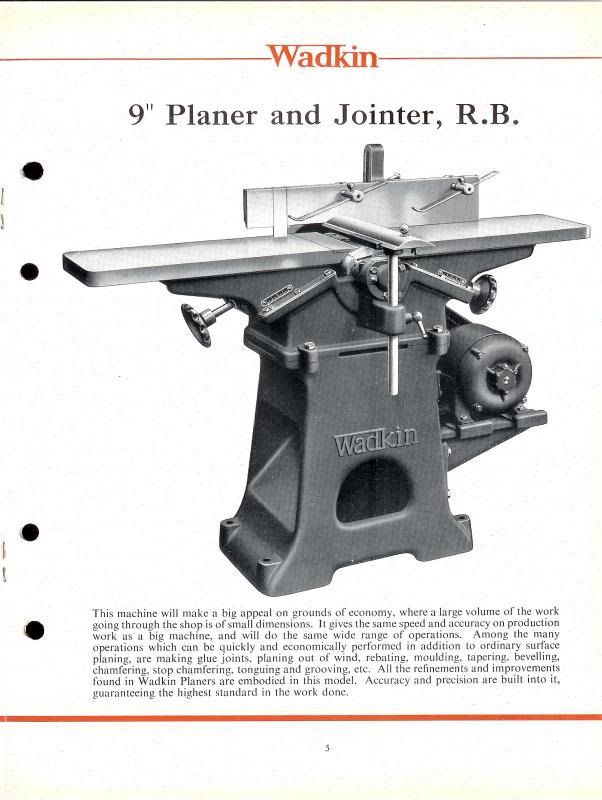

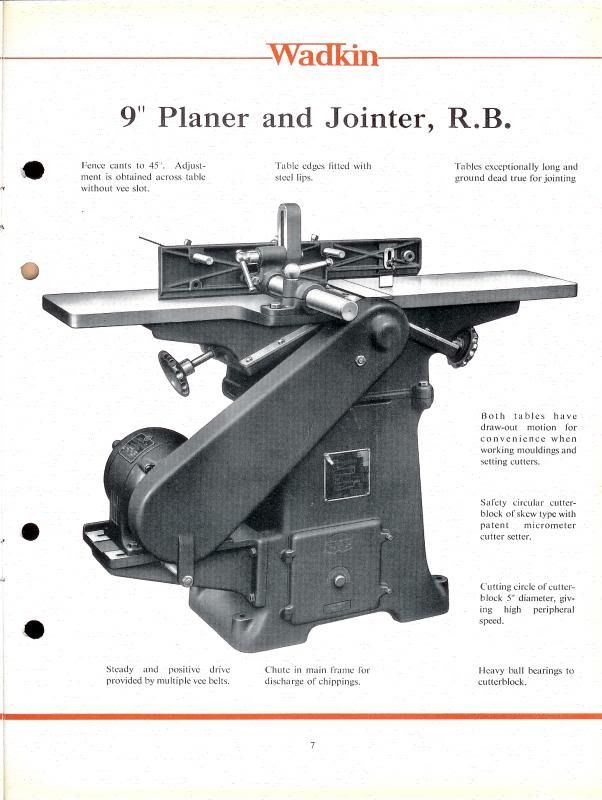

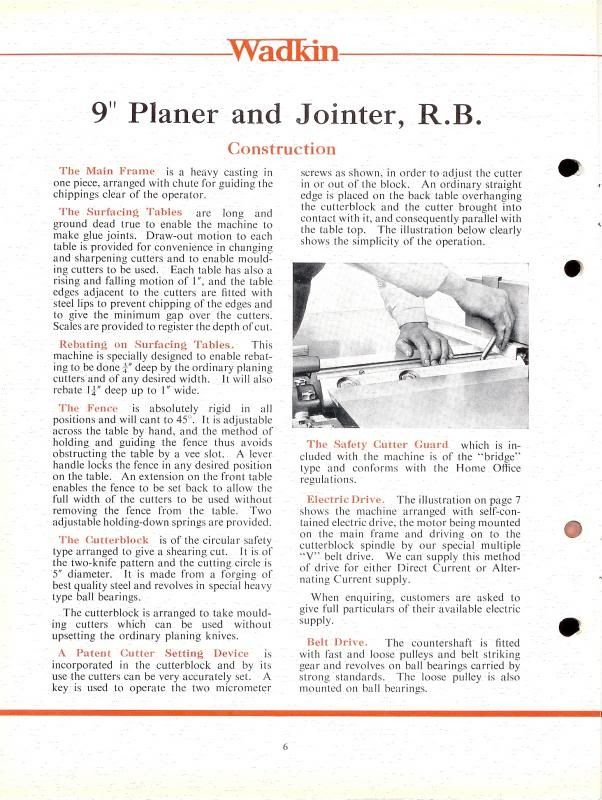

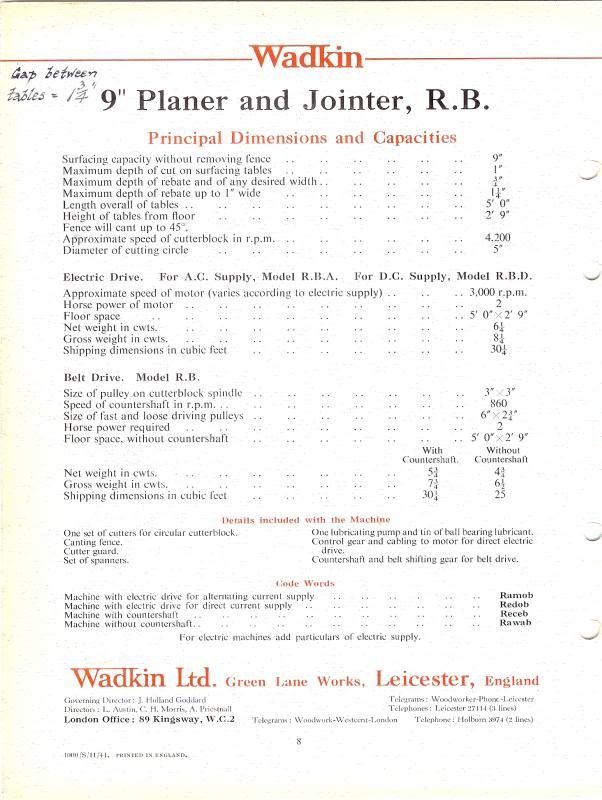

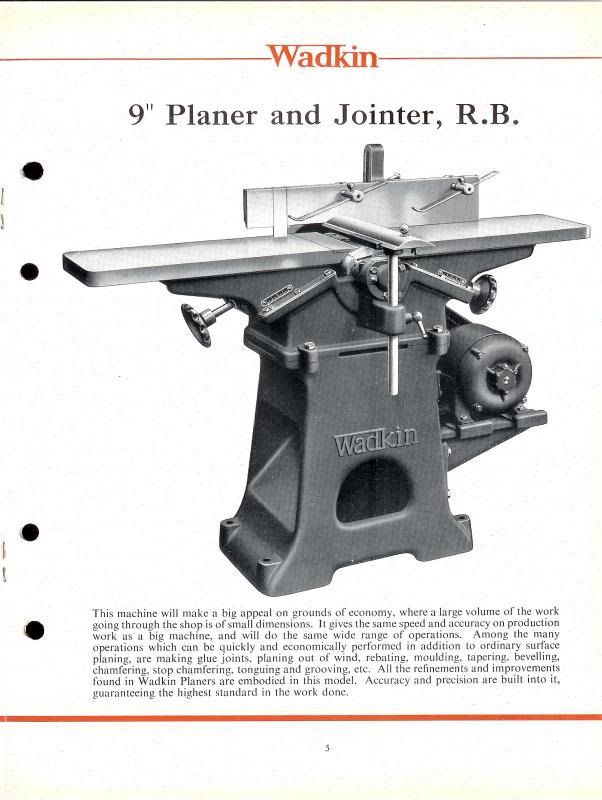

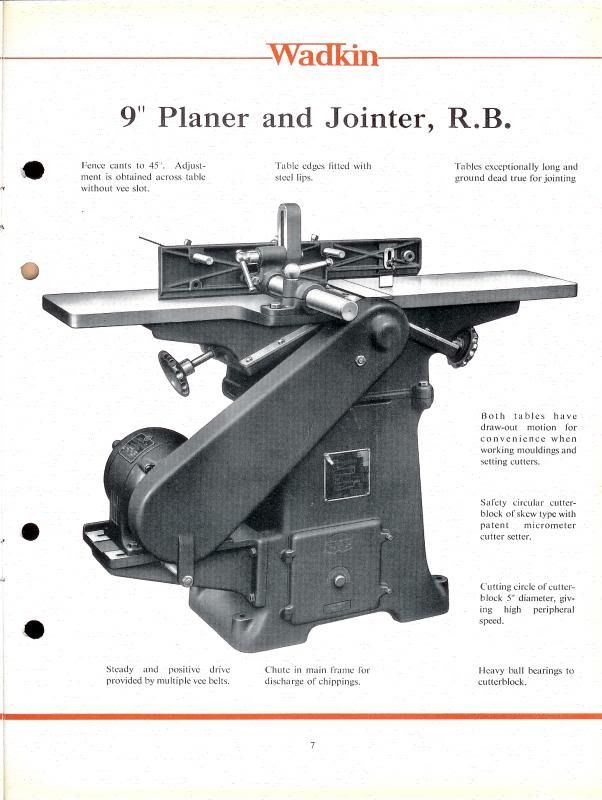

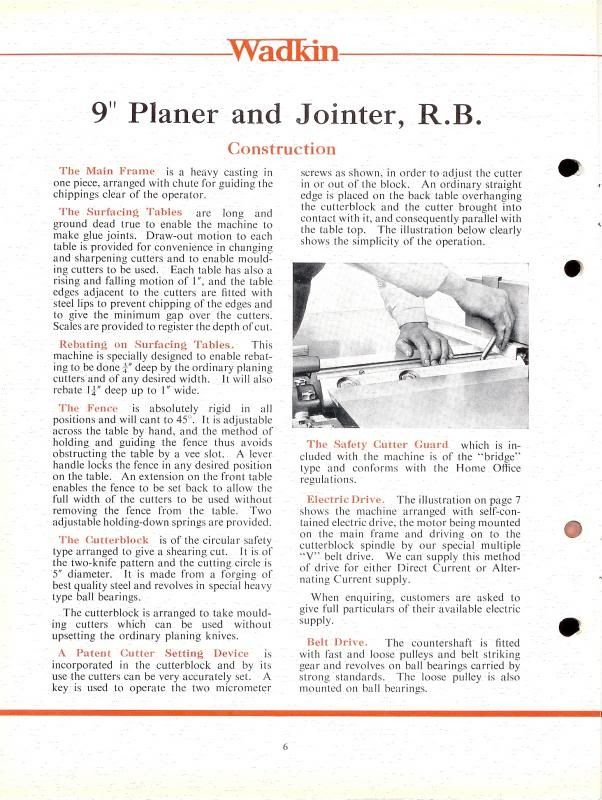

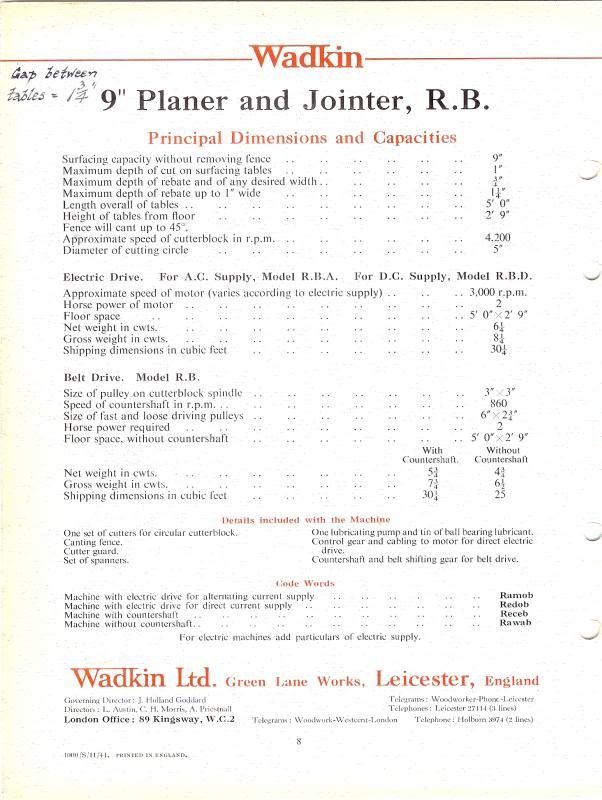

This catalogue scan from 1941 shows an updated model with a rack and pinon fence;

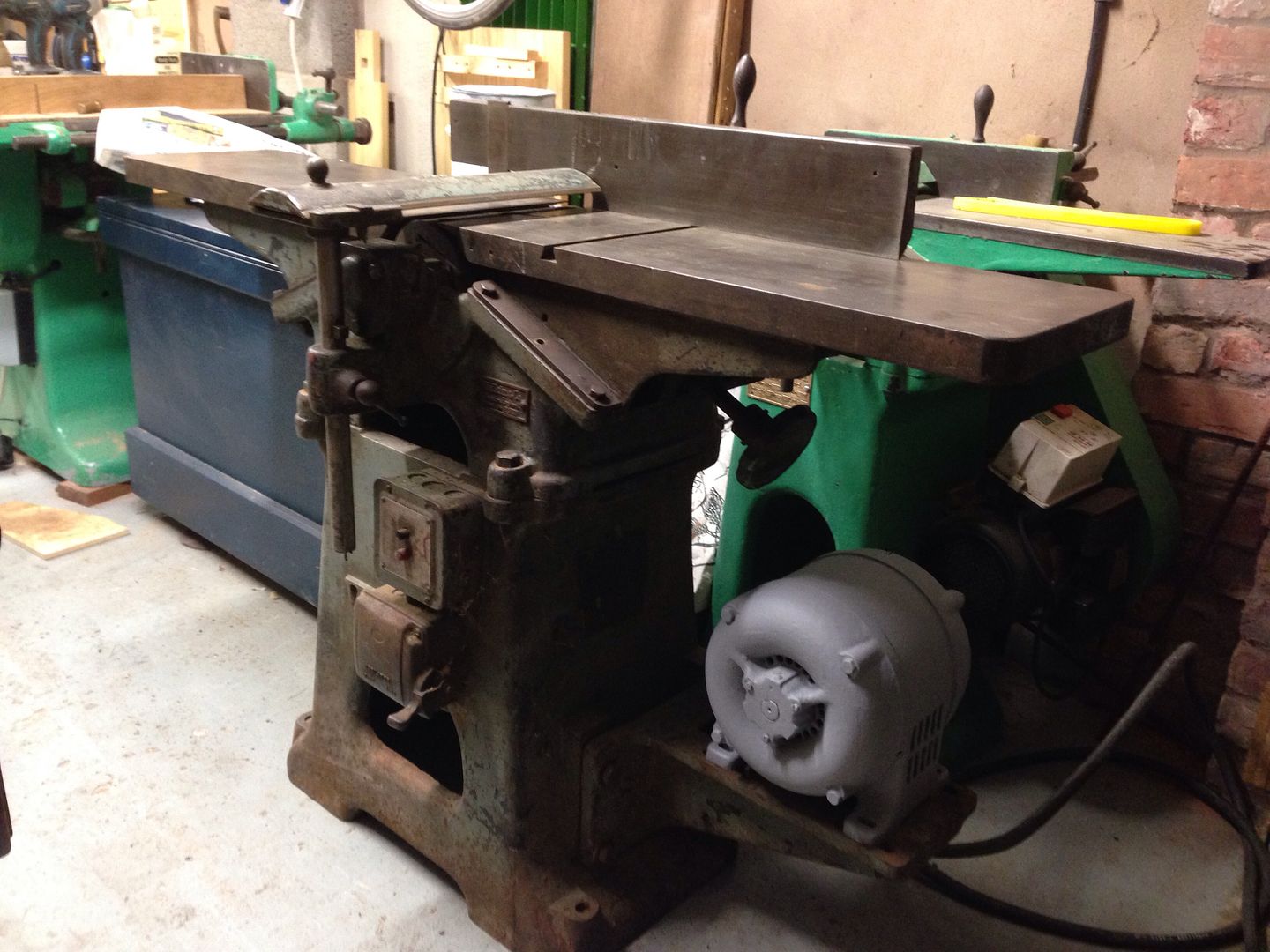

Here's the machine as it got it, it came with a single phase motor however I happened to have an original motor kicking around, while it looks rough, it was mechanically fine.

A blast with the pressure washer removed most of the poorly applied green paint and dust;

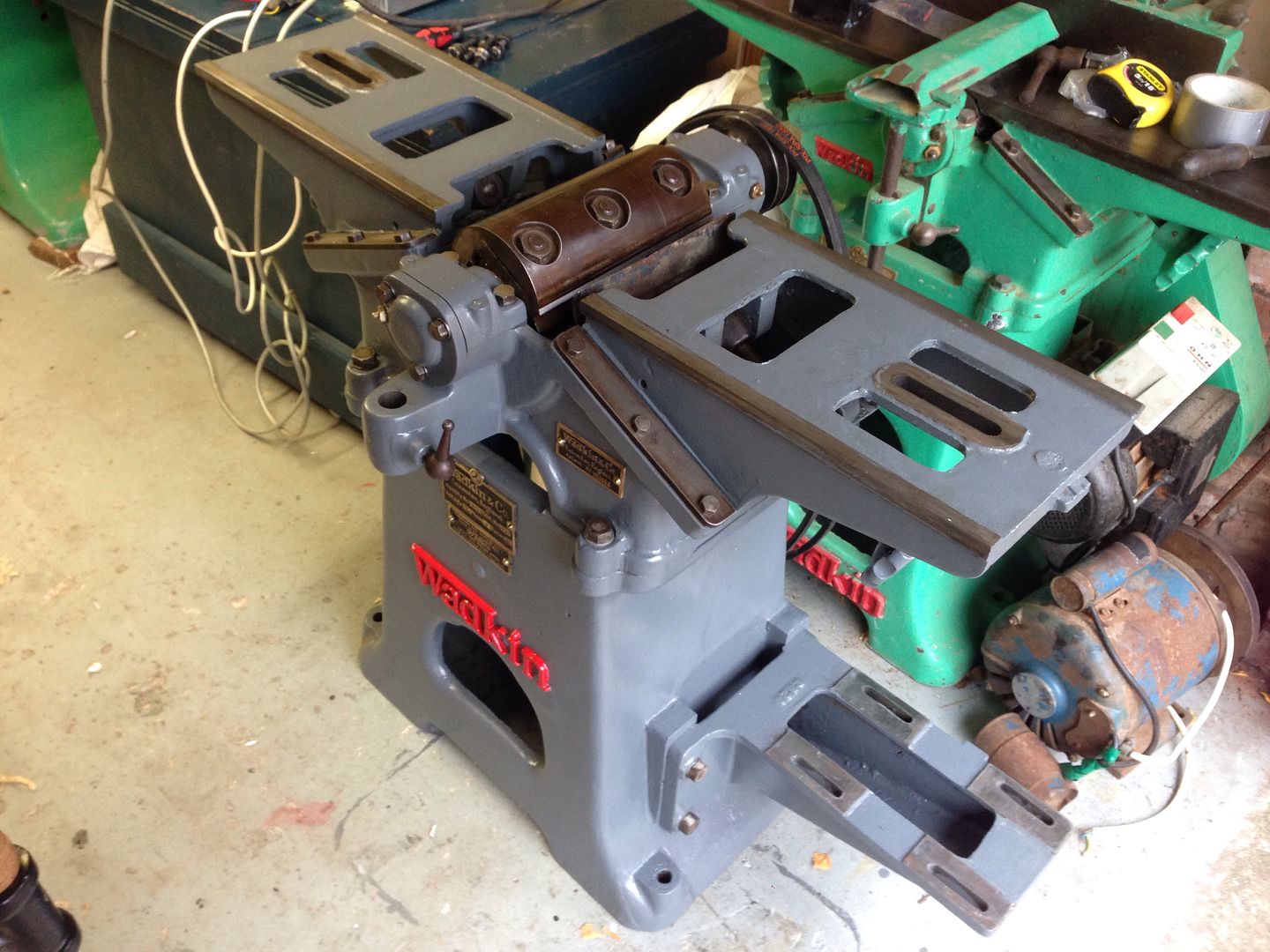

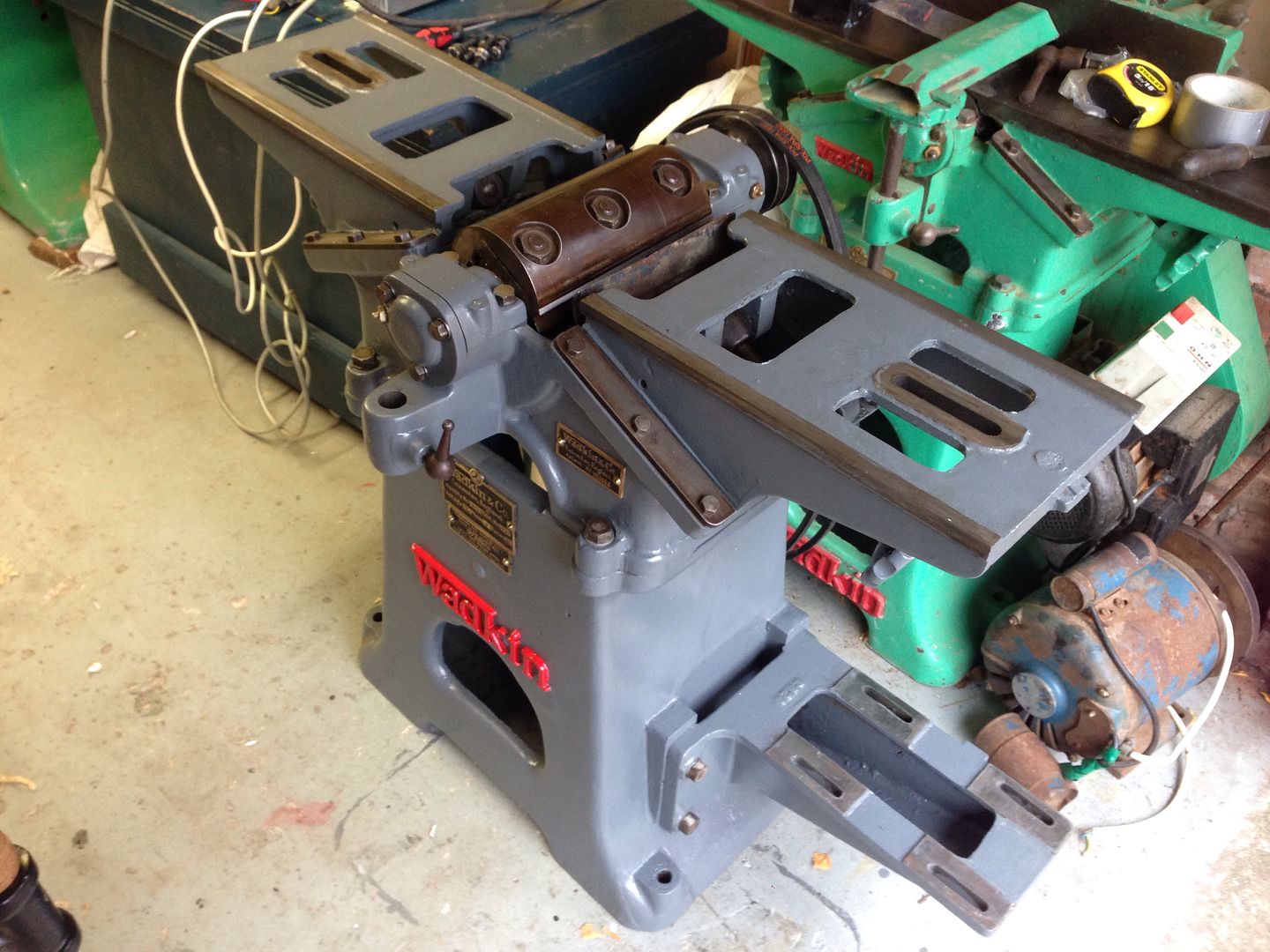

Everything was rubbed down and painted with machinery enamel, the type i'm using doesn't require a primer. Skip forward a couple of weeks and it's mostly painted and the head is back in. The bearings are Swedish made SKF 2306 double row self-aligning so are very likely to be replacements. The head was clocked up and with some 'encouraged' no movement was found so the bearings appeared to be in good condition.

The motor I'm using was originally 415v three phase, I wanted to run it using 240v single phase, to do this the star point is extracted from the motor windings and three additional wires are connected, this allows the motor to be run at 240v in delta configuration. The motor is controlled via a Bosch Rexroth digital inverter which is located in the machine base.

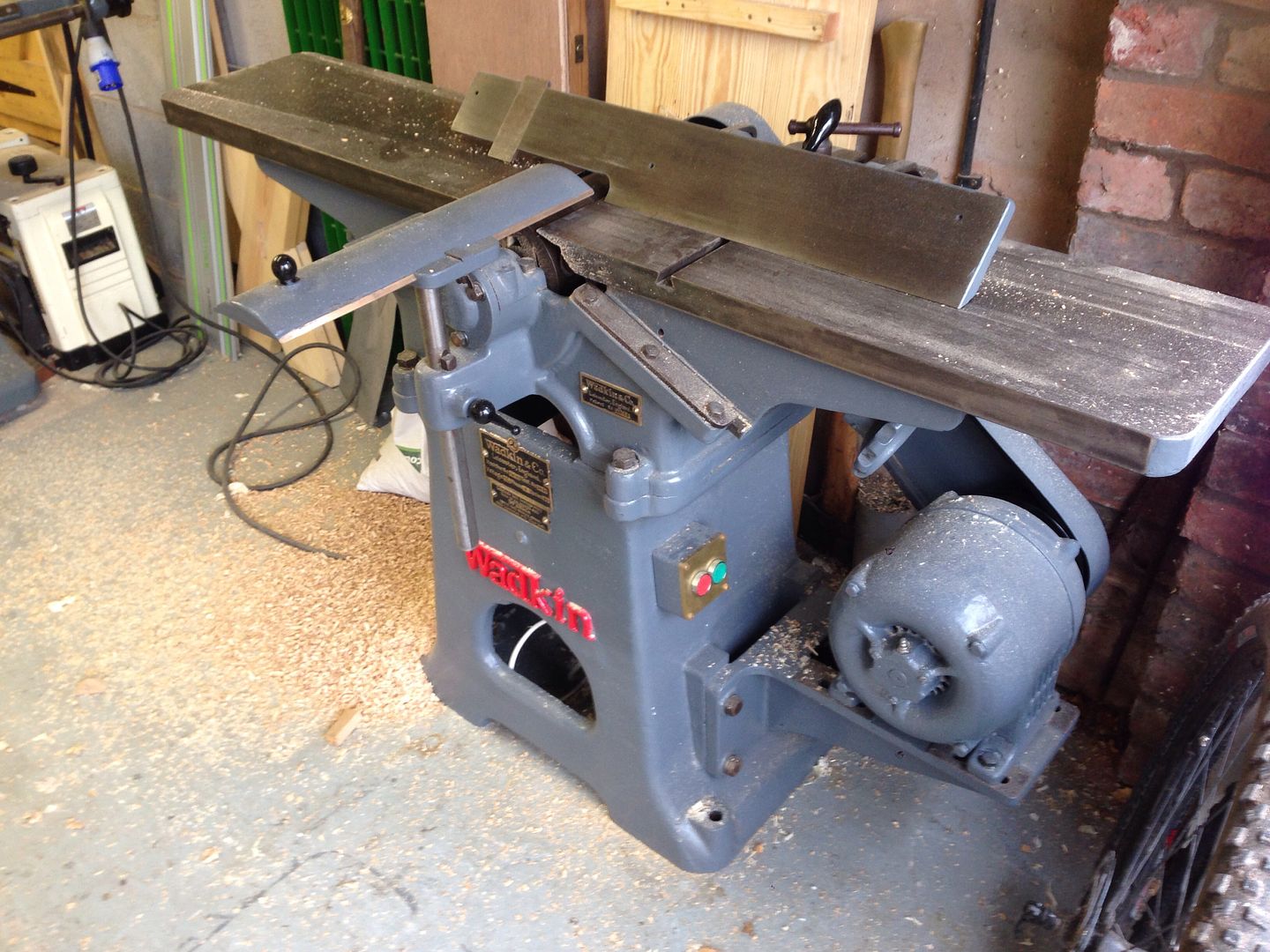

Finally the finished machine (well almost, I've fitted a brass cover for the controls since taking these pictures);

The shewed head makes some big shavings!

Cheers (hammer)

This machine dates from 1937, I don't know when production started however the fence tells me this is one of the earlier machines. It will plane boards up to 9" in width. The segmented head allows moulding cutters to be fitted without disturbing the planing knives, the tables retract to give the required clearance when moulding cutters and allow quick access to the head.

The head is 5" in diameter with a skewed cut, the finish it leaves is impressive.

This catalogue scan from 1941 shows an updated model with a rack and pinon fence;

Here's the machine as it got it, it came with a single phase motor however I happened to have an original motor kicking around, while it looks rough, it was mechanically fine.

A blast with the pressure washer removed most of the poorly applied green paint and dust;

Everything was rubbed down and painted with machinery enamel, the type i'm using doesn't require a primer. Skip forward a couple of weeks and it's mostly painted and the head is back in. The bearings are Swedish made SKF 2306 double row self-aligning so are very likely to be replacements. The head was clocked up and with some 'encouraged' no movement was found so the bearings appeared to be in good condition.

The motor I'm using was originally 415v three phase, I wanted to run it using 240v single phase, to do this the star point is extracted from the motor windings and three additional wires are connected, this allows the motor to be run at 240v in delta configuration. The motor is controlled via a Bosch Rexroth digital inverter which is located in the machine base.

Finally the finished machine (well almost, I've fitted a brass cover for the controls since taking these pictures);

The shewed head makes some big shavings!

Cheers (hammer)