wallace

Established Member

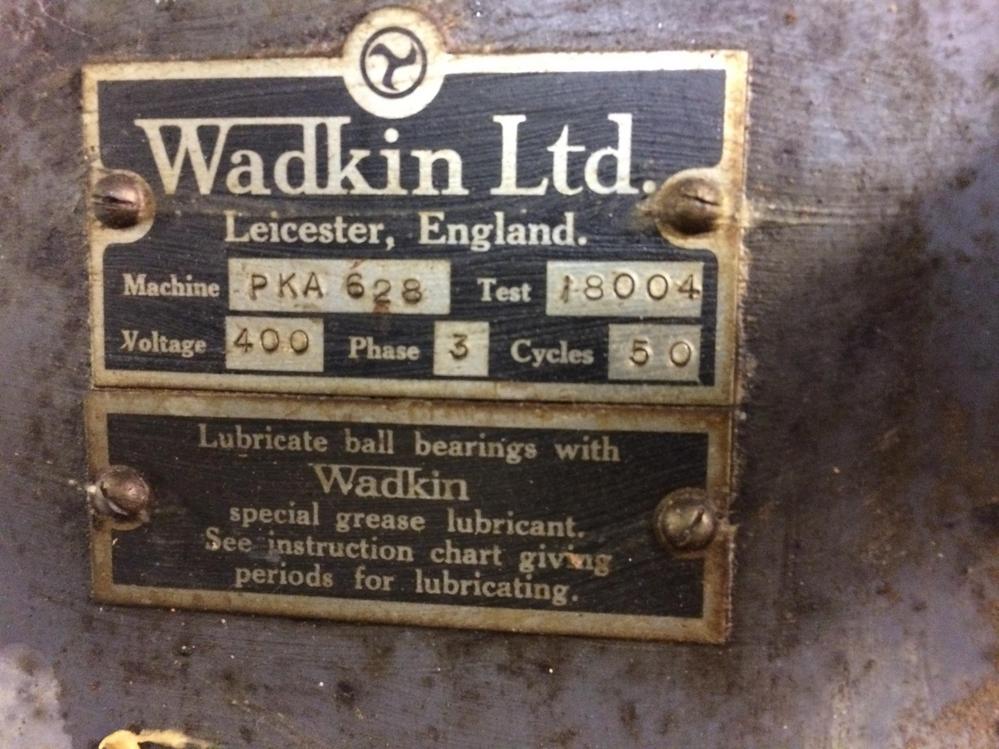

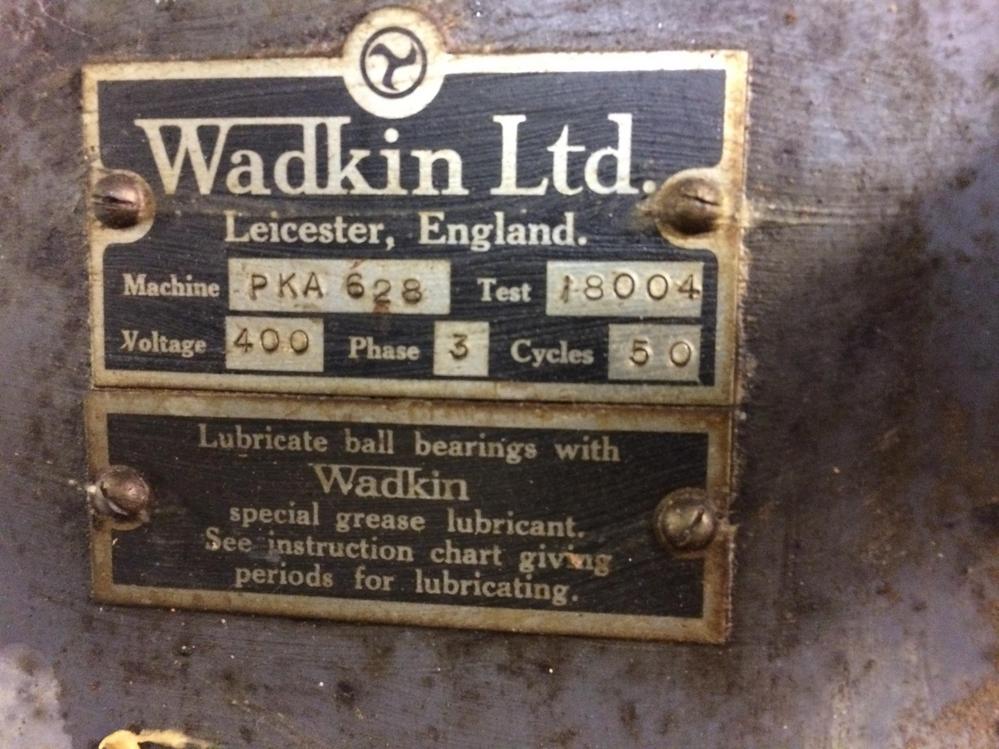

I sold my beloved pk recently so to cheer myself up I bought another one. The old one had really big tables and took up a lot of room in my shed. This one is normal sized.

Its a rough old thing

This one dates from 1941

some one never believed in extraction

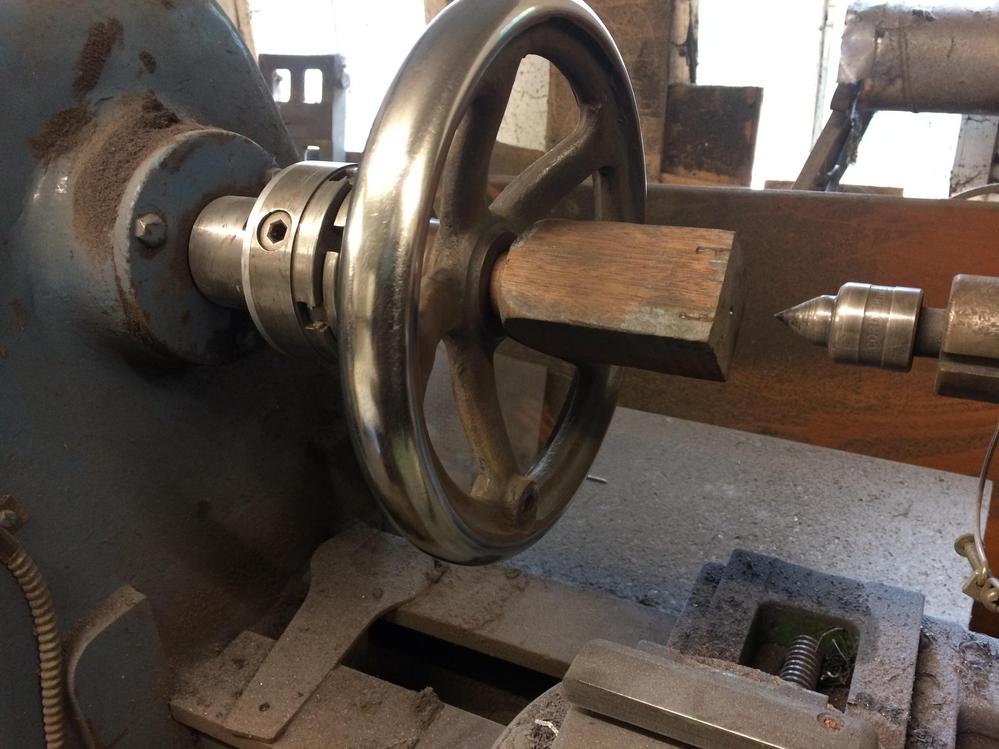

Im surprised the tilt and raise still worked

Its a rough old thing

This one dates from 1941

some one never believed in extraction

Im surprised the tilt and raise still worked