wallace

Established Member

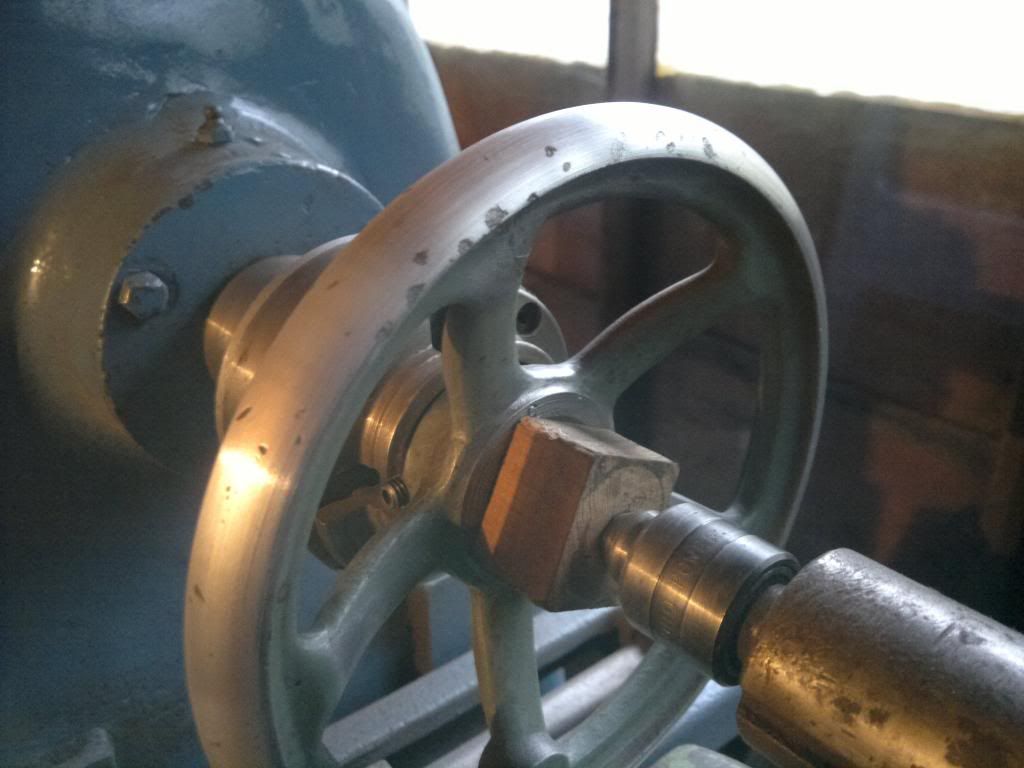

I bought this a little while ago and had no intention of restoring it because it looked in good nick. That was until I tried to start it and the motor went really slowly and the bobbin did not go up and down. It needed to be stripped cleaned and lubed up. So I thought I may as well 'wallace' it while I was on.

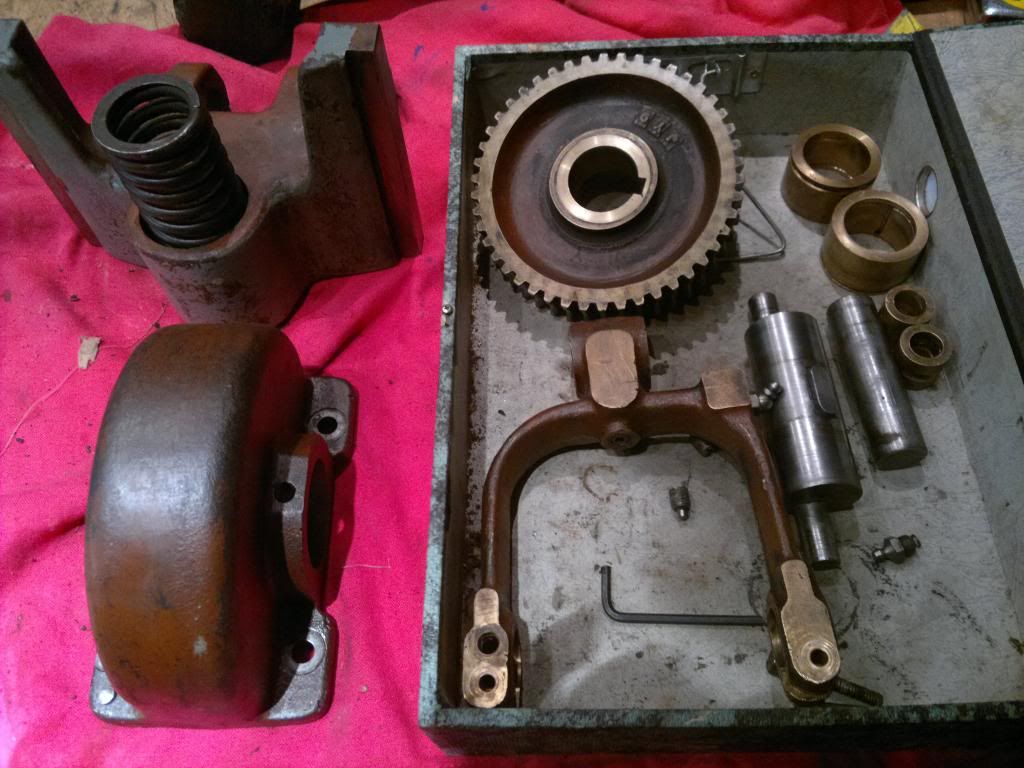

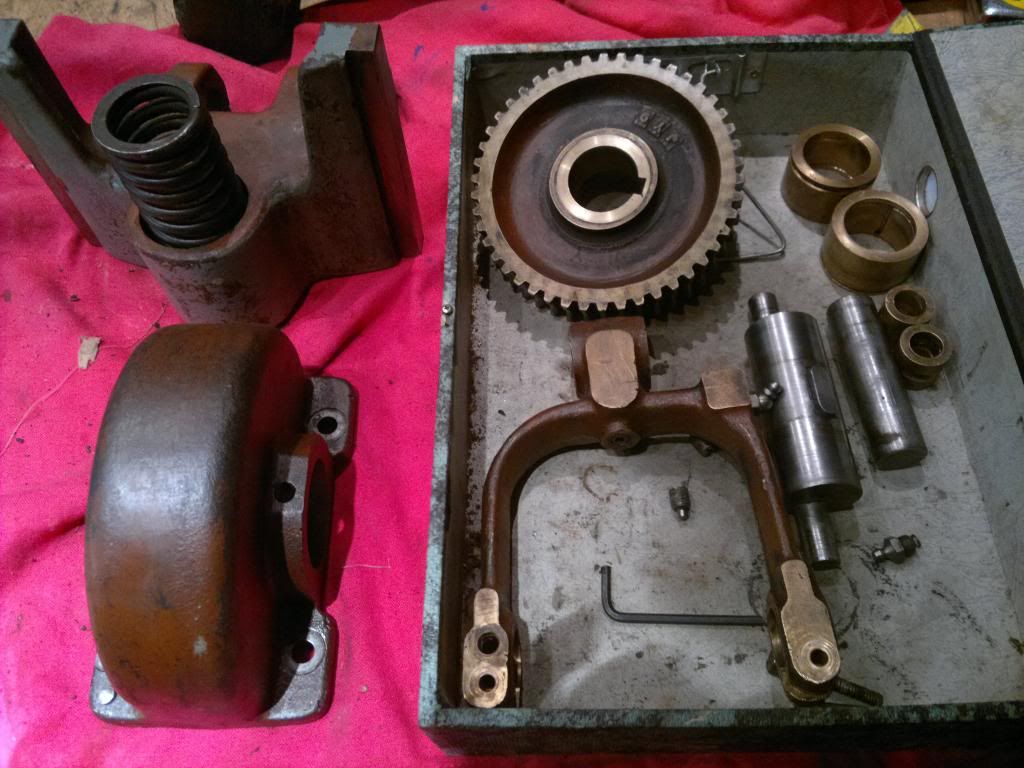

Everything is packed solid with a plaster type powder

There are six wires coming from the motor but 3 are taped off. Maybe these were two speed? Anyone have one to clarify

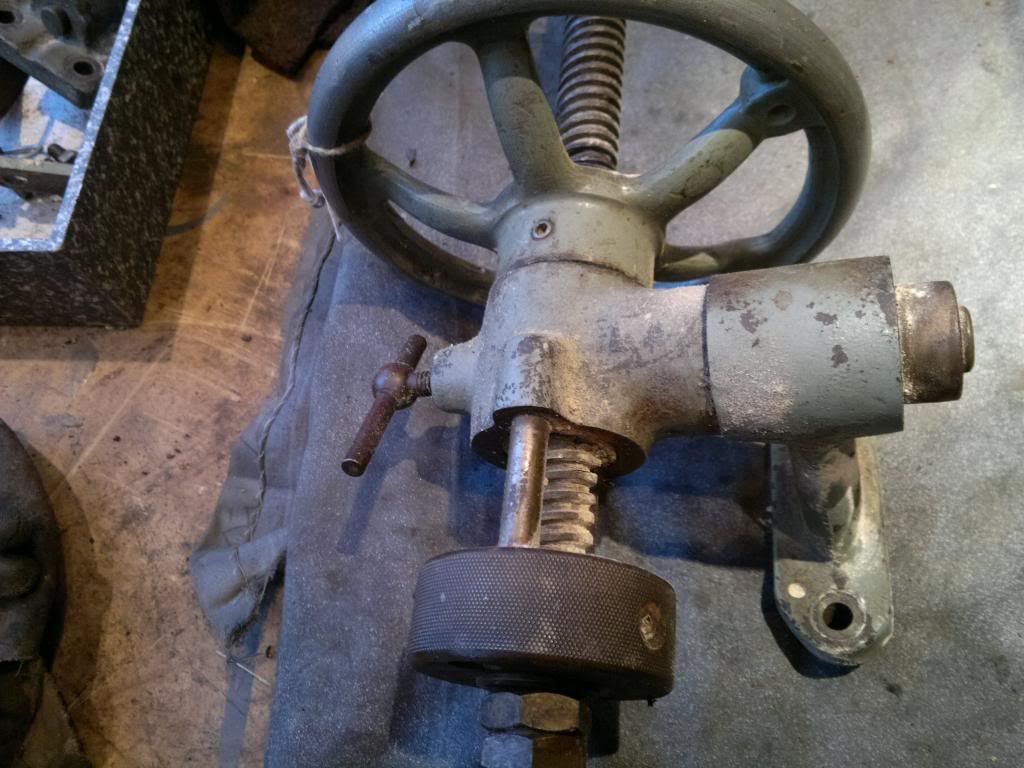

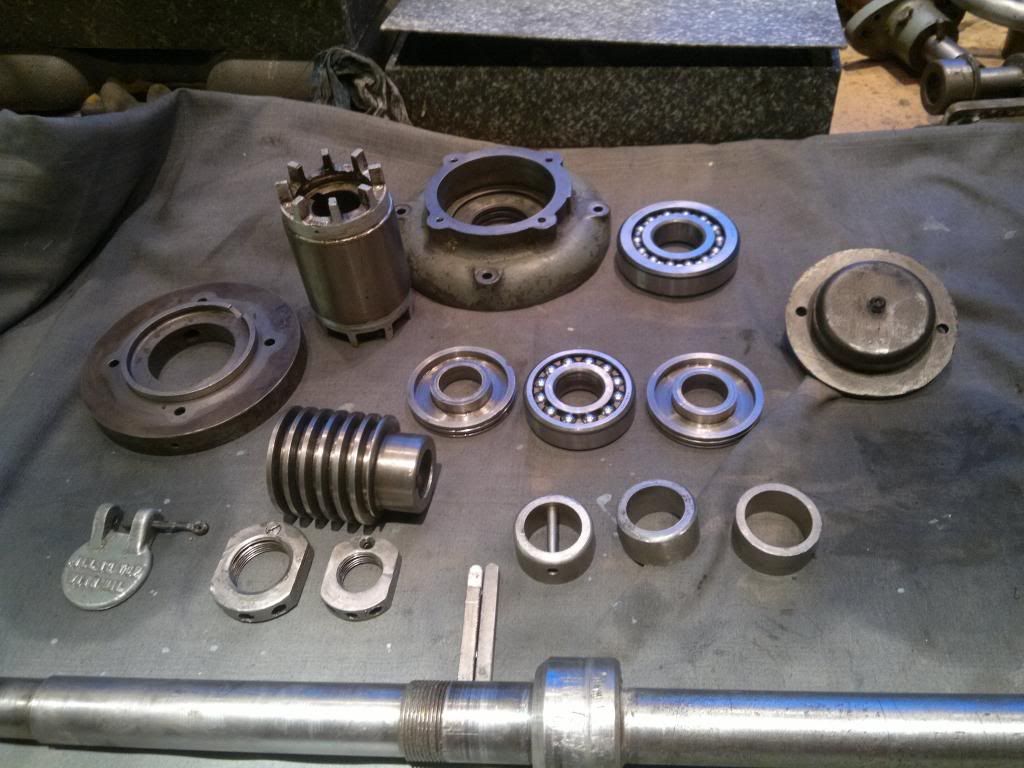

It took about 1.5hrs to get everything stripped off

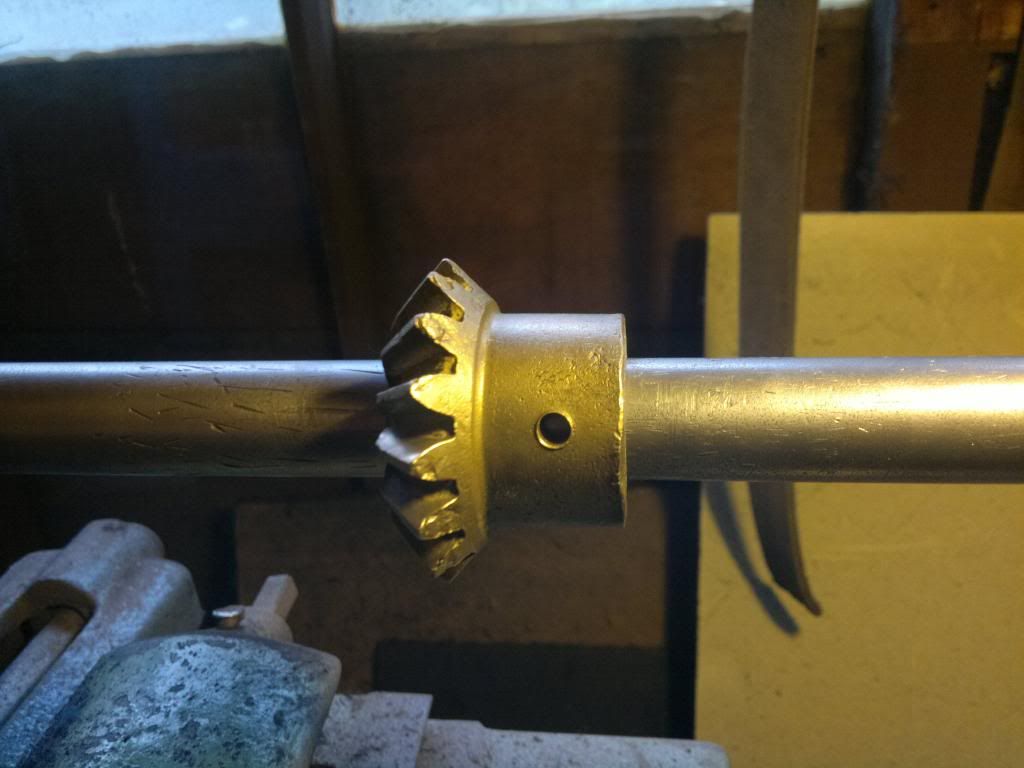

This is the bit that makes the bobbin bob all stripped and cleaned

Everything is packed solid with a plaster type powder

There are six wires coming from the motor but 3 are taped off. Maybe these were two speed? Anyone have one to clarify

It took about 1.5hrs to get everything stripped off

This is the bit that makes the bobbin bob all stripped and cleaned