You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

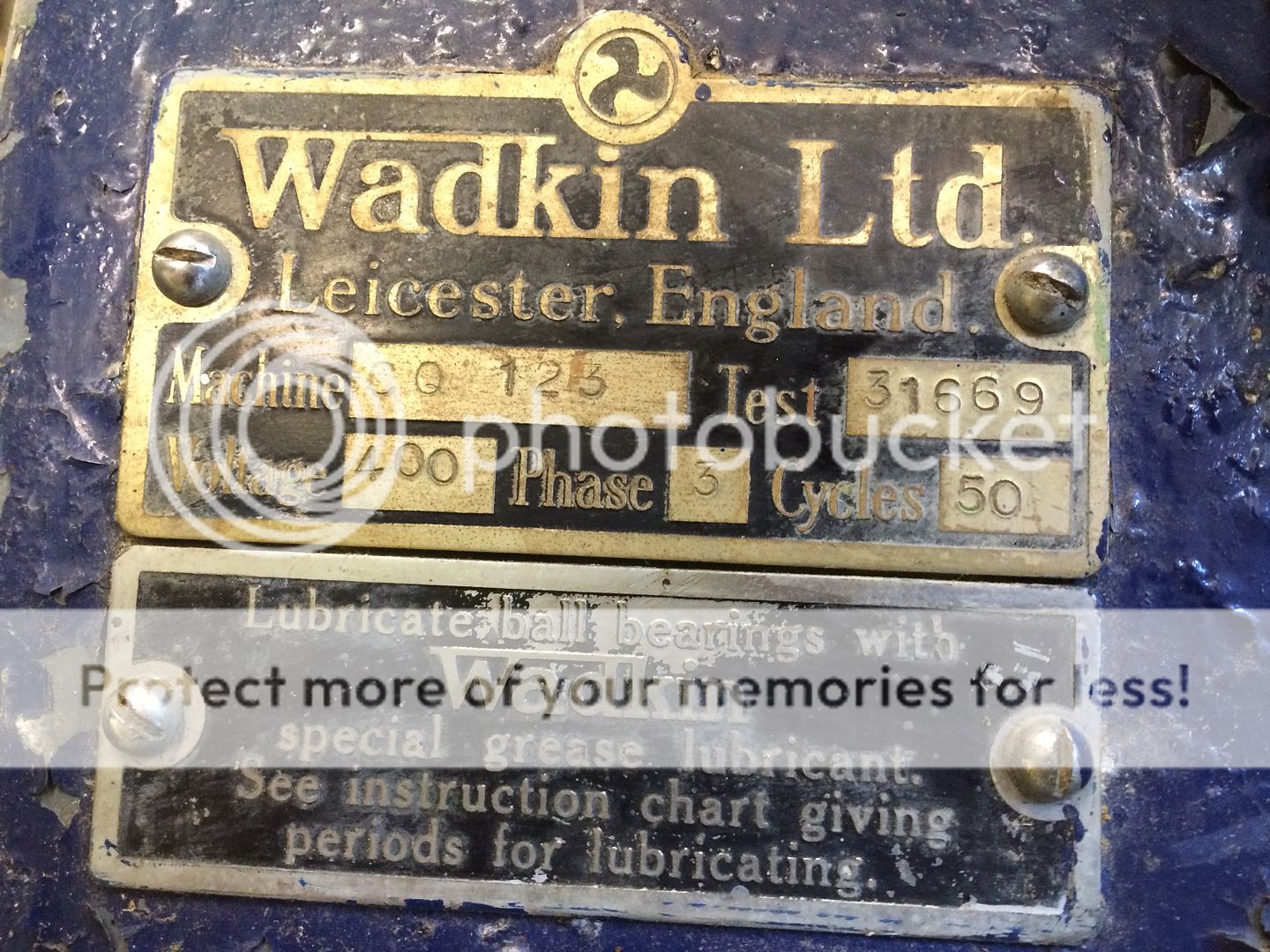

Wadkin CO restoration

- Thread starter wallace

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Random Orbital Bob

Established Member

Strap in and lock on folks....here we go again

One thing I seem to remember from somewhere is that in the immediate post-war period aluminium was a lot easier to obtain than steel; the reason that many relatively low production cars of the period which were not likelly to contribute to exports were made largely from aluminium.

Jim

Jim

Excellent. Looking forward to that beast coming back to life.

Also. That's a really good comment there giantbeast. How about some youtube videos?

I've been to the supermarket and bought some Doritos, dip and a few tins. Now let's see the magic happen.

Jonny

Also. That's a really good comment there giantbeast. How about some youtube videos?

I've been to the supermarket and bought some Doritos, dip and a few tins. Now let's see the magic happen.

Jonny

wallace

Established Member

I did think about some vids but not sure how interesting it would be to watch me sit and sand a chunk of metal for 2hrs

Random Orbital Bob

Established Member

wallace":19mbxynt said:I did think about some vids but not sure how interesting it would be to watch me sit and sand a chunk of metal for 2hrs

If well edited they could work but I think just more gratuitous pictures of hefty lumps of beautifully restored (before and after) cast iron in all its glorious shapes is what the kids want

wallace

Established Member

I find the taking to bits really fun for some reason. I used to always get wrong for taking my toys to bits as a kid

On trying to take the spindle to bits I had some problems getting the blade clamp off. It would normally just come off with a puller, but it was having none of it. And then I bent the disc. You normally get a feel for how much pressure to put on something and I didn't think I'd gone too heavy handed.

I took the spindle out and it became clear why I bent it. It had been repaired by brazing. To get the spindle out I put the nut back on to protect the threads, cover with wood and hit with a big boy hammer oh and heat it up.

On trying to take the spindle to bits I had some problems getting the blade clamp off. It would normally just come off with a puller, but it was having none of it. And then I bent the disc. You normally get a feel for how much pressure to put on something and I didn't think I'd gone too heavy handed.

I took the spindle out and it became clear why I bent it. It had been repaired by brazing. To get the spindle out I put the nut back on to protect the threads, cover with wood and hit with a big boy hammer oh and heat it up.

Woodmonkey

Established Member

If it's not a stupid question (or even if it is) what is it??

wallace

Established Member

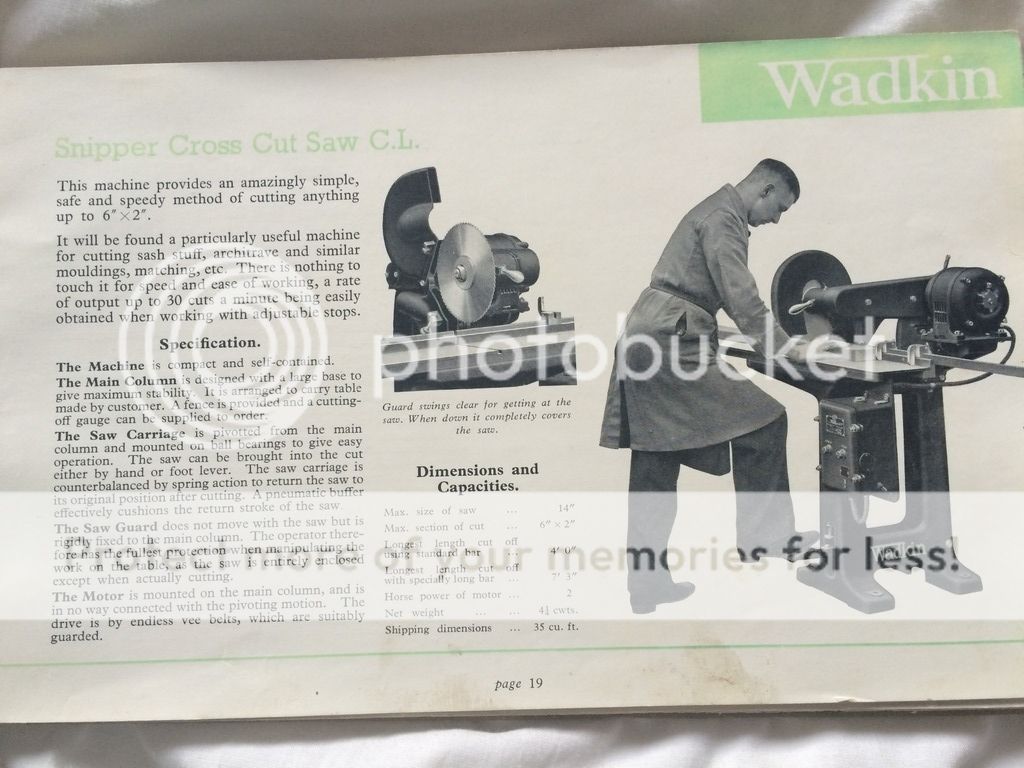

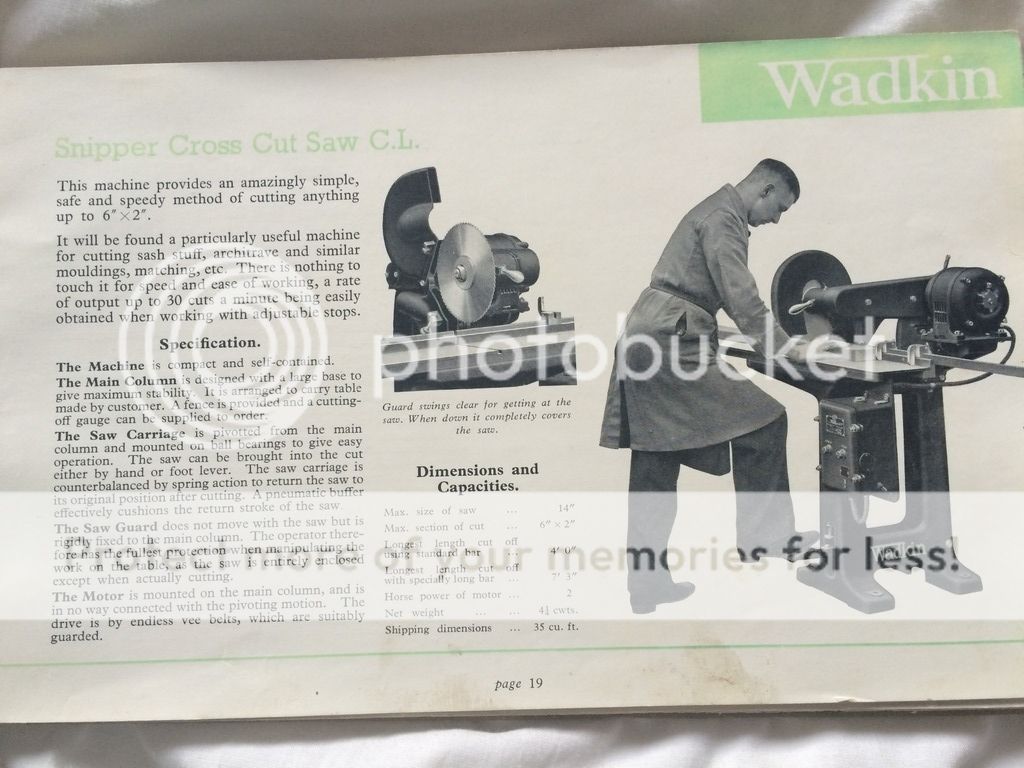

Its a chop saw, it has a 14" blade. Its meant for fast production of straight cuts. The catalogue says upto 30 cuts per minute using the foot pedal

Woodmonkey

Established Member

Wow sounds deadly!

Random Orbital Bob":3gdlgfou said:wallace":3gdlgfou said:I did think about some vids but not sure how interesting it would be to watch me sit and sand a chunk of metal for 2hrs

If well edited they could work but I think just more gratuitous pictures of hefty lumps of beautifully restored (before and after) cast iron in all its glorious shapes is what the kids want

thats what i was thinking, just set up a cam & edit it down, or another good one is the time lapse camera, that would be good.

i do enjoy a good video, watching somone scrape away rust & rebuild something is far better than James Martins British Cooking Bake Sunday Oven Bunch or whatever my other half keeps watching which seems to be on every day with only a 5 minute break.

Was going to ask that myself if noone admitted to similar ignorance!!Woodmonkey":2mls6ymp said:If it's not a stupid question (or even if it is) what is it??

But intrigued by the TWO vee belts used to drive it. What sort of power is there to need that much muscle?

t8hants

Established Member

+1, I was to shy to ask!

thick_mike

Wood Shortener

t8hants":2xqshws3 said:+1, I was to shy to ask!

He asked what we were all wondering!

wallace

Established Member

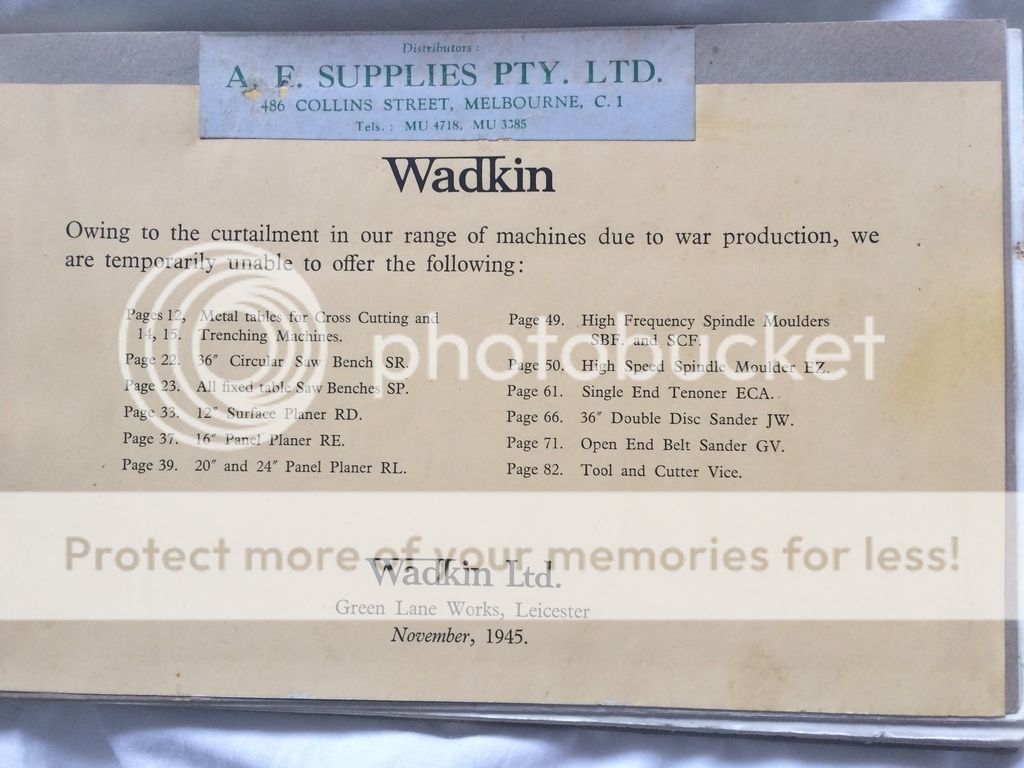

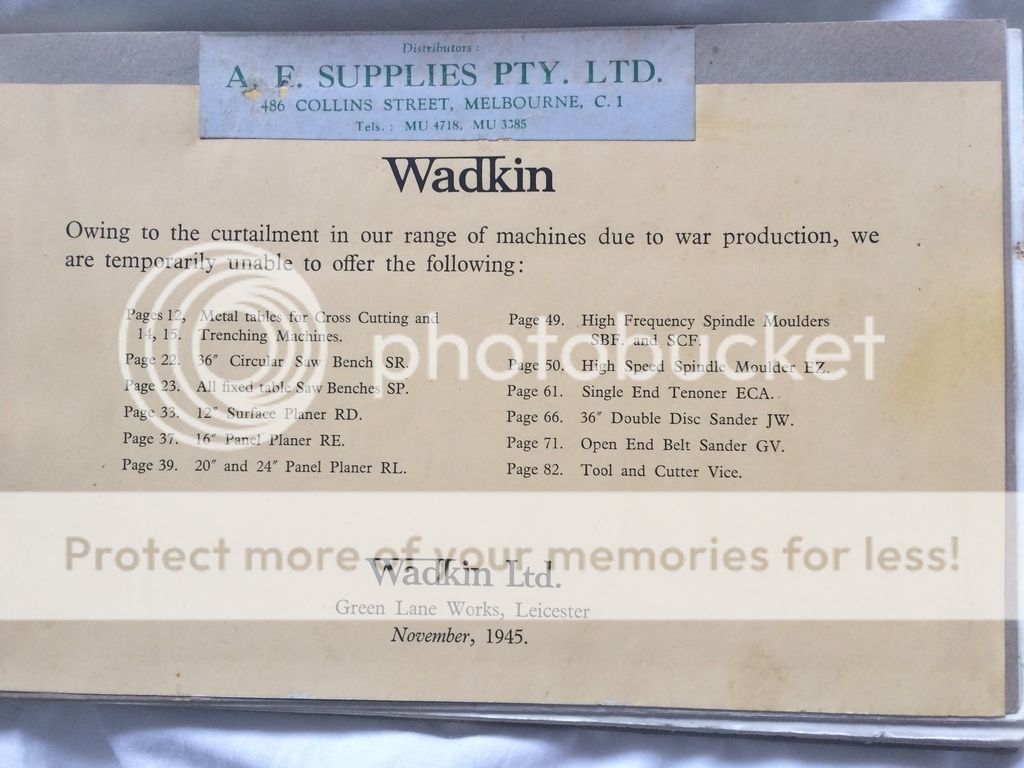

Heres a close relative of the saw I'm doing a CL

For the Australian contingent, this was stuck into the same catalogue

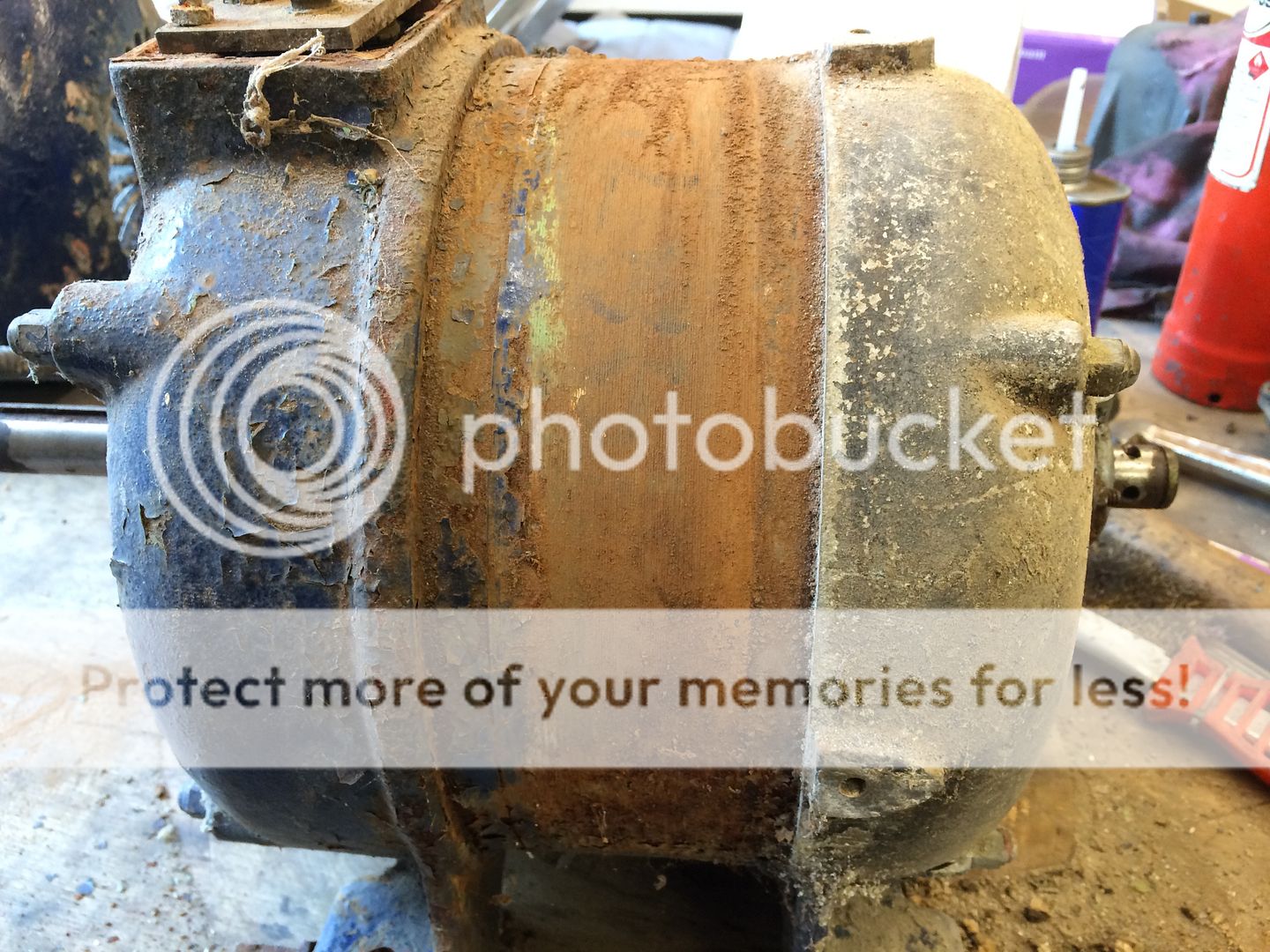

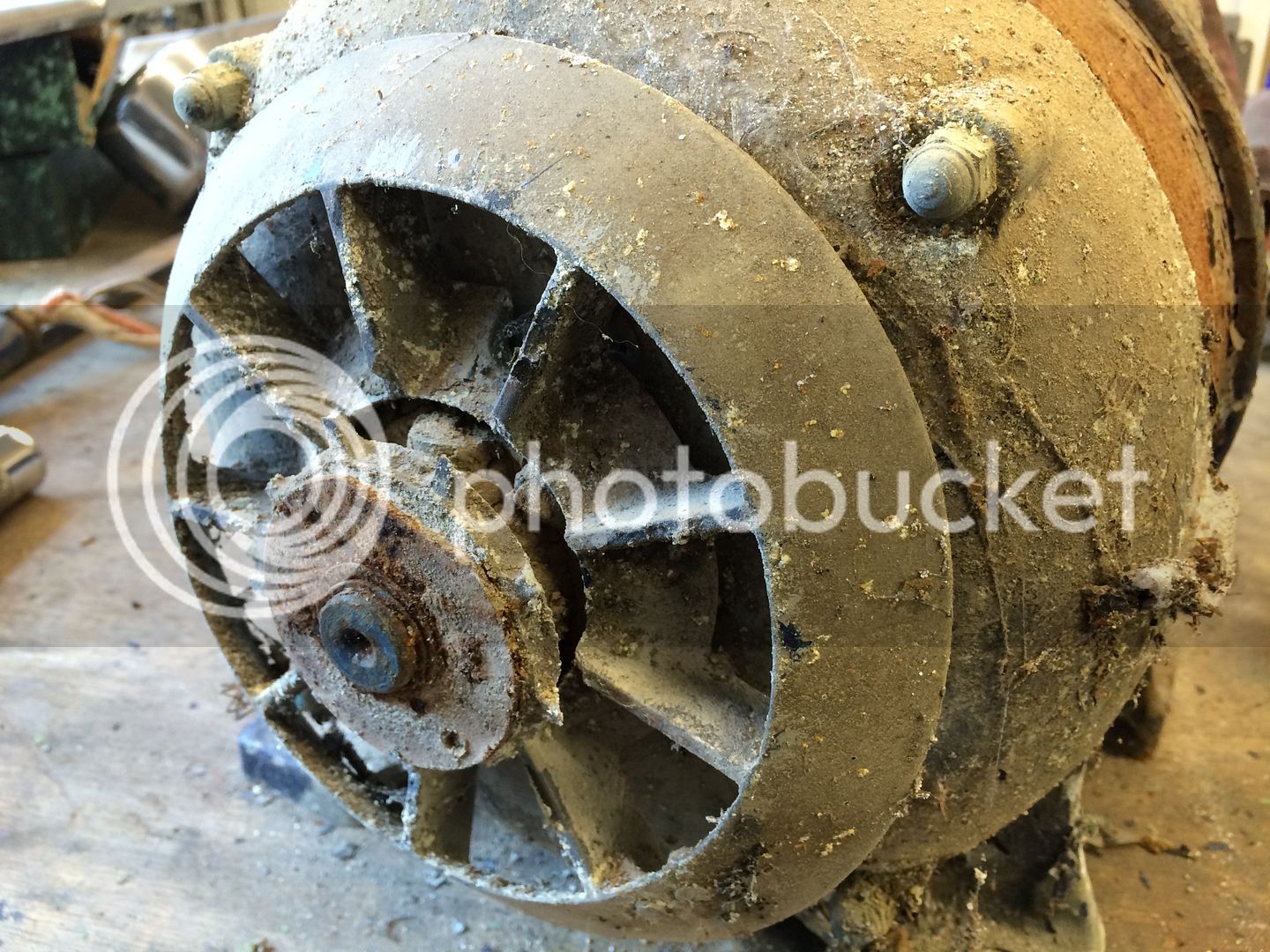

Because this is cast aluminium I'm taking extra precautions when dismantling. Things are getting a good soak in plus gas and like this bit a little heat.

I thought the bearings in the pivot a little overkill. The pivot on the mitre saw I did was just a bushing.

I was taking a pic of a box of parts and noticed the end cap for the pivot broken.

Looks like its been cracked for a while.

Everything is stripped ready to de gunge

For the Australian contingent, this was stuck into the same catalogue

Because this is cast aluminium I'm taking extra precautions when dismantling. Things are getting a good soak in plus gas and like this bit a little heat.

I thought the bearings in the pivot a little overkill. The pivot on the mitre saw I did was just a bushing.

I was taking a pic of a box of parts and noticed the end cap for the pivot broken.

Looks like its been cracked for a while.

Everything is stripped ready to de gunge

wallace

Established Member

wallace

Established Member

MattRoberts

Established Member

I could look at your progress for hours - it's remarkably therapeutic!

Similar threads

- Replies

- 1

- Views

- 123

- Replies

- 0

- Views

- 280