Hello all! I'm new to posting though I have read many posts on this forum and learned a lot. I'm a retired academic/industrial engineer, who used to design very high precision equipment ... but in those days I had someone to make them for me  . I've had formal training in both metal and woodwork, but haven't had the long hours of experience that many forum members have had, and I find the contributions on this forum really helpful.

. I've had formal training in both metal and woodwork, but haven't had the long hours of experience that many forum members have had, and I find the contributions on this forum really helpful.

I've recently become a happy owner of a 1960s ish Wadkin AGS10 (serial 622988) and am putting it into service. I wouldn't call it a restoration as it is in excellent shape: flat table, fence running and adjusting smoothly, bearings seem sound as do the mechanisms, apart from a bit of play in the rise-and-fall but I guess that is normal for the age and seems quite acceptable. However I have a question on the pinion that does the fine adjustment on the fence (parts 18, 19 and 20 on page 3 of the 'older AGS model' manual in the Wadkin Library). This item is worn almost conical at the end and could do with replacing or at least reversing if that is possible. I have a two questions on this:

1. Does anyone know the pitch of the rack (D.P. of the pinion gear)?

2. Does anyone know how the pinion, shaft and handle are assembled? Can the pinion be reversed on the shaft or is it integral? I can't see any screw or pin holes, so it may have been pressed together inside its Oilite bush and the whole pressed into the rip fence front bracket (part 17). But I thought I'd ask before applying force to get it out!

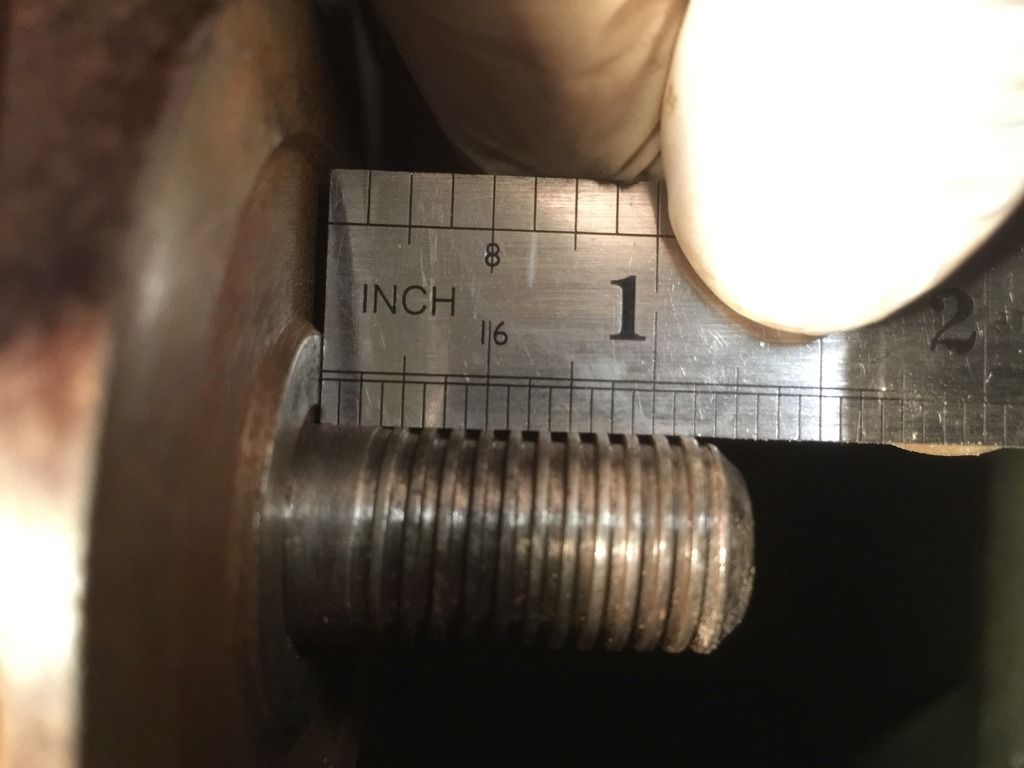

It is also missing the 3/8" BSW x 1" bolt, part 15 on page 2, which goes into the spindle housing. I removed this bolt to move the spindle so that the blade and riving knife are aligned, and found that it was actually a metric bolt that did not engage any threads but appeared to have been stuck on with the repaint job! I presume this should be the proper bolt, and that the through hole is large enough to allow a little adjustment for this alignment. Can someone confirm that this is how it would work? It is unsurprising that the arbor had crept a little to far out of the housing if this bolt was not making contact. I am not sunning up the motor till a replacement bolt arrives.

Finally, the Wadkin manual talks about 'ranging down' a blade, by what seems a pretty hairy procedure. I have never heard of this process but presume it is to make sure that the blade is cutting on all teeth evenly and not just the highest one. Does anyone still do this? Or is it not necessary with modern blades? (presumably never with TCT blades).

Many thanks in advance for any replies

Keith

I've recently become a happy owner of a 1960s ish Wadkin AGS10 (serial 622988) and am putting it into service. I wouldn't call it a restoration as it is in excellent shape: flat table, fence running and adjusting smoothly, bearings seem sound as do the mechanisms, apart from a bit of play in the rise-and-fall but I guess that is normal for the age and seems quite acceptable. However I have a question on the pinion that does the fine adjustment on the fence (parts 18, 19 and 20 on page 3 of the 'older AGS model' manual in the Wadkin Library). This item is worn almost conical at the end and could do with replacing or at least reversing if that is possible. I have a two questions on this:

1. Does anyone know the pitch of the rack (D.P. of the pinion gear)?

2. Does anyone know how the pinion, shaft and handle are assembled? Can the pinion be reversed on the shaft or is it integral? I can't see any screw or pin holes, so it may have been pressed together inside its Oilite bush and the whole pressed into the rip fence front bracket (part 17). But I thought I'd ask before applying force to get it out!

It is also missing the 3/8" BSW x 1" bolt, part 15 on page 2, which goes into the spindle housing. I removed this bolt to move the spindle so that the blade and riving knife are aligned, and found that it was actually a metric bolt that did not engage any threads but appeared to have been stuck on with the repaint job! I presume this should be the proper bolt, and that the through hole is large enough to allow a little adjustment for this alignment. Can someone confirm that this is how it would work? It is unsurprising that the arbor had crept a little to far out of the housing if this bolt was not making contact. I am not sunning up the motor till a replacement bolt arrives.

Finally, the Wadkin manual talks about 'ranging down' a blade, by what seems a pretty hairy procedure. I have never heard of this process but presume it is to make sure that the blade is cutting on all teeth evenly and not just the highest one. Does anyone still do this? Or is it not necessary with modern blades? (presumably never with TCT blades).

Many thanks in advance for any replies

Keith