White House Workshop

Established Member

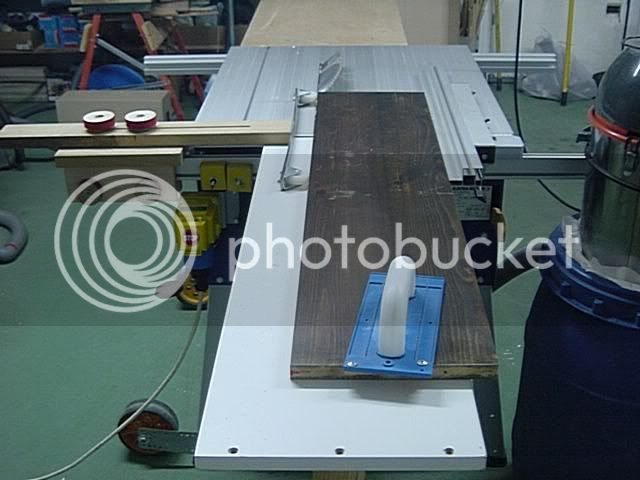

On long versus short fences... When I was being taught to use the tablesaw the instructor stressed that there were always two measurements to take, the first was at the front of the blade for the correct width of cut and the second was at the back of the blade to make sure it was the same! Most tablesaws come with fences that are notoriously inaccurate and that clamp front and back. One day I'll be able to afford a Biesemeyer fence set-up......