Klaus Kretschmar

Established Member

Hi Handtoolers,

who doesn't know the situation while dovetailing or while doing some other jobs where you'd like to have a little more clamping height than a bench allows. The double screw vice (also called Moxon vice), that can be mounted onto the bench might be the solution. I say it might be because it's important that the additional vice offers clamping qualities as you are used from your bench as there is the easy handling and most important the reliable clamping power that is easy to handle. A quick built vice that moves while sawing dovetails or that doesn't clamp powerful probably won't see too much use...

That to be said, I was lucky enough to get the d-vice from Douglas Coates to do some testing work with it. I've the vice in use and want to report my first impressions here. When I unpacked the parcel and saw it the first time, I was immediately impressed with the obvious quality it shows as there is the perfect workmanship that you can spot on every detail. Sturdy oak legs (65 x 50 x 360 mm) that allow to alter the working height on my bench from 103 cm up to about 120 cm. Not less stable the beech cheeks (37 x 100 x 560 mm).

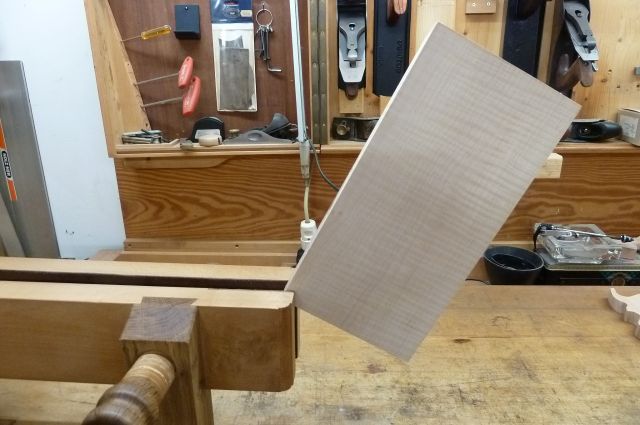

The dovetailed joint between legs and cheeks is done second to none. The following pic shows it clearly and it shows another very nice feature. The screws have bosses at the front and at the back. The bosses themselves are out of holm oak that was turned with high attention to detail, very nice to behold and very comfortable to touch and to use.

A close-up of the front boss with ebony peg that not only serves as thumb rest while clamping. The pegs on both front bosses are aligned in a way that they show clearly when the jaws are parallel. That is a very nice feature that shines when you need to pre adjust the opening before inserting the workpiece. Just open the jaws a little more than the thickness of the workpiece by keeping them parallel. Then a little turn of both front (or rear) bosses by leaving the pegs aligned and the workpiece is clamped the best possible way.

The clamping power is surprisingly high by turning the bosses effortlessly, rather amazing.

One of the keys for the stunning clamping power might be the leather coat of the front cheek.

Two more features: into the left end of the rear jaw a thick leather piece is inserted and the rear jaw has a vertical vee, that allows the proper claamping of round stock.

There is another most important and really impressive feature that can't be seen. The front cheek is gartered. While opening the vice the front cheek is running back (unlike all other double svrew vices I've seen so far). This little feature is shining bright if you use the far ends for clamping. Just close the near boss and open the far a little bit and the workpiece is clamped perfectly.

As you will probably spot, the vice is flipped backside in front while using the double leather coated end. My bench is standing rather near to the left wall so there is little space to work at the left side. No problem with the d-vice. The both sided bosses allow it to mount the vice in both ways into the bench vice without comfort loss.

One last word to the tool quality. The operating of it is pure joy. The screws are running very smoothly with extremely little play. I really don't know how Douglas managed it to make it run that easy and smooth unlike many other wood screw driven vices that I came across so long. The vice is a very useful -and joyful- addition to my bench that will see lots of use for sure.

If you'd ask me if I didn't find a downside I'd say no I didn't indeed.

My sincerest compliments to you Douglas!

Klaus

who doesn't know the situation while dovetailing or while doing some other jobs where you'd like to have a little more clamping height than a bench allows. The double screw vice (also called Moxon vice), that can be mounted onto the bench might be the solution. I say it might be because it's important that the additional vice offers clamping qualities as you are used from your bench as there is the easy handling and most important the reliable clamping power that is easy to handle. A quick built vice that moves while sawing dovetails or that doesn't clamp powerful probably won't see too much use...

That to be said, I was lucky enough to get the d-vice from Douglas Coates to do some testing work with it. I've the vice in use and want to report my first impressions here. When I unpacked the parcel and saw it the first time, I was immediately impressed with the obvious quality it shows as there is the perfect workmanship that you can spot on every detail. Sturdy oak legs (65 x 50 x 360 mm) that allow to alter the working height on my bench from 103 cm up to about 120 cm. Not less stable the beech cheeks (37 x 100 x 560 mm).

The dovetailed joint between legs and cheeks is done second to none. The following pic shows it clearly and it shows another very nice feature. The screws have bosses at the front and at the back. The bosses themselves are out of holm oak that was turned with high attention to detail, very nice to behold and very comfortable to touch and to use.

A close-up of the front boss with ebony peg that not only serves as thumb rest while clamping. The pegs on both front bosses are aligned in a way that they show clearly when the jaws are parallel. That is a very nice feature that shines when you need to pre adjust the opening before inserting the workpiece. Just open the jaws a little more than the thickness of the workpiece by keeping them parallel. Then a little turn of both front (or rear) bosses by leaving the pegs aligned and the workpiece is clamped the best possible way.

The clamping power is surprisingly high by turning the bosses effortlessly, rather amazing.

One of the keys for the stunning clamping power might be the leather coat of the front cheek.

Two more features: into the left end of the rear jaw a thick leather piece is inserted and the rear jaw has a vertical vee, that allows the proper claamping of round stock.

There is another most important and really impressive feature that can't be seen. The front cheek is gartered. While opening the vice the front cheek is running back (unlike all other double svrew vices I've seen so far). This little feature is shining bright if you use the far ends for clamping. Just close the near boss and open the far a little bit and the workpiece is clamped perfectly.

As you will probably spot, the vice is flipped backside in front while using the double leather coated end. My bench is standing rather near to the left wall so there is little space to work at the left side. No problem with the d-vice. The both sided bosses allow it to mount the vice in both ways into the bench vice without comfort loss.

One last word to the tool quality. The operating of it is pure joy. The screws are running very smoothly with extremely little play. I really don't know how Douglas managed it to make it run that easy and smooth unlike many other wood screw driven vices that I came across so long. The vice is a very useful -and joyful- addition to my bench that will see lots of use for sure.

If you'd ask me if I didn't find a downside I'd say no I didn't indeed.

My sincerest compliments to you Douglas!

Klaus