devonwoody

Established Member

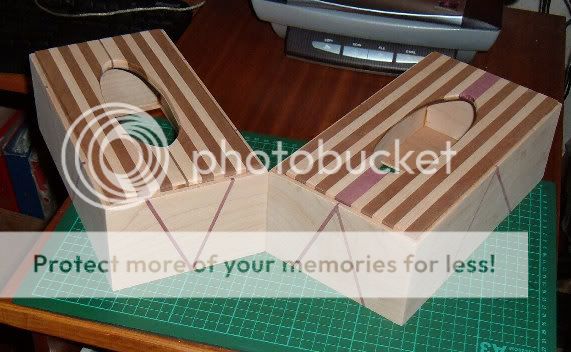

V for Victory tissue box to celebrate the English test match win at Lords over Australia 20th July 09 first since 1934.

Started a new box with intarsia design. V or Victory.

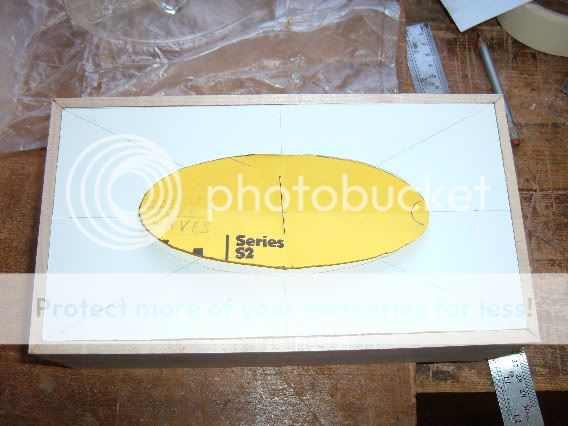

Prepared 4 Sycamore boards to 10mm thickness to make some more tissue boxes.

Then marked up boards ready for routering dadoes to v design. Put three boards down to give support to hand held router and fixed a spacing board over timbers to guide router and cut out.

Various screws and clamps were needed to hold everything in position but things went very well.

So glued in the p/h , cut mitred corner joints and glued up the carcass.

Started a new box with intarsia design. V or Victory.

Prepared 4 Sycamore boards to 10mm thickness to make some more tissue boxes.

Then marked up boards ready for routering dadoes to v design. Put three boards down to give support to hand held router and fixed a spacing board over timbers to guide router and cut out.

Various screws and clamps were needed to hold everything in position but things went very well.

So glued in the p/h , cut mitred corner joints and glued up the carcass.