Philly

Established Member

Hi Folks

Following a conversation with Jimi I thought I'd post these pics in a separate thread - hopefully they will be of use to someone.

Recently Tormek have been advertising a kit to allow you to use the tormek guides on your highspeed grinder. And, needing a second guide for my grinder I was tempted to get one (especially as my Tormek sits around un-used). But, being lazy, I thought I'd have a go at making one myself.

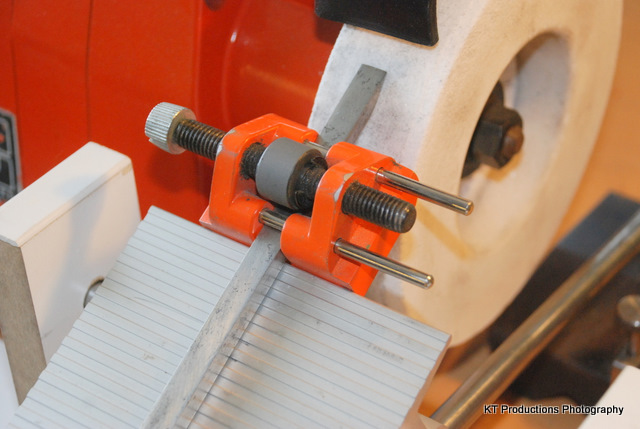

So, after bashing a couple of pieces of wood around and drilling a couple of holes, we end up with this.....

I used metal threaded inserts from Screwfix (M6) and a couple of Philly Planes brass knobs to lock the arm in position. And in practise it works great! All the usual jigs fit and you can use the angle finder jig to set it exactly where you want it.

Hope this helps - if anyone needs any more details just ask.

Cheers

Philly

Following a conversation with Jimi I thought I'd post these pics in a separate thread - hopefully they will be of use to someone.

Recently Tormek have been advertising a kit to allow you to use the tormek guides on your highspeed grinder. And, needing a second guide for my grinder I was tempted to get one (especially as my Tormek sits around un-used). But, being lazy, I thought I'd have a go at making one myself.

So, after bashing a couple of pieces of wood around and drilling a couple of holes, we end up with this.....

I used metal threaded inserts from Screwfix (M6) and a couple of Philly Planes brass knobs to lock the arm in position. And in practise it works great! All the usual jigs fit and you can use the angle finder jig to set it exactly where you want it.

Hope this helps - if anyone needs any more details just ask.

Cheers

Philly