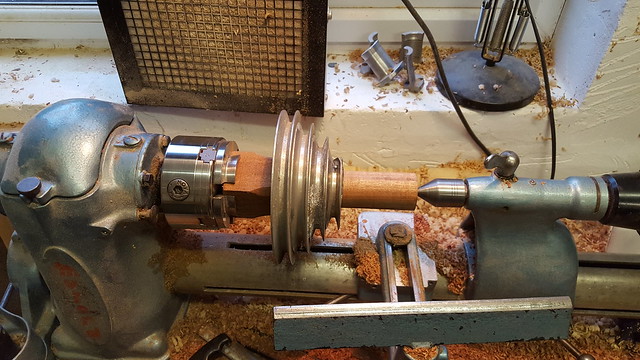

I've bought a slightly rough (read-very rough!) graduate on ebay to do up to be my "forever" lathe. It's big enough and heavy enough to tackle anything I'm going to want to do. It all started when the bearings gave up on my myford's motor. I bought a 3 phase motor and inverter to make it variable speed, then spotted this union lathe about 20 miles from me. Man maths prevailed and I decided I could better use the inverter and 3 phase motor in it rather than my myford.... Replaced the motor in the myford with a 240v one so I could continue turning while I got the big 'un running. It's not going to be up to the standards of one of wallace's wadkin resto's but it should look pretty when I'm done! So without further ado, here she is:

2016-11-06_10-43-59

2016-11-06_10-43-59

20161103_184126

20161103_184126

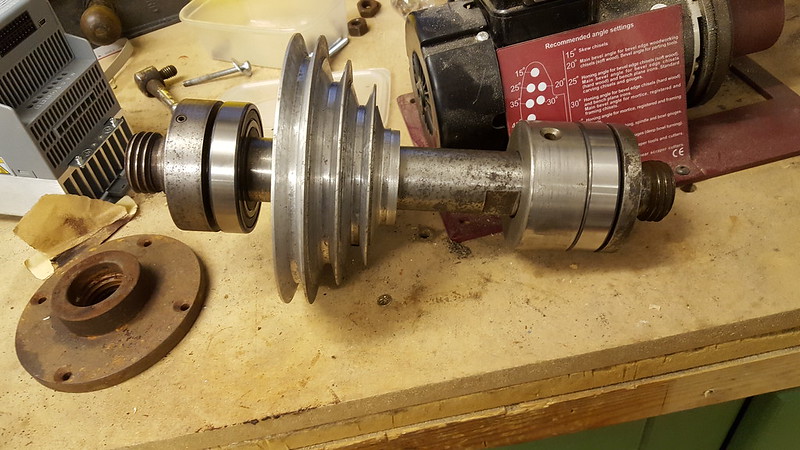

The Drive centre was firmly rusted in. Progressively bigger hammers took care of that. I then set about removing the spindle. After much lump hammer action, it was all moving apart from the outboard spacer. The one that holds it all in! I drilled and tapped the two existing holes in it to get a puller on it:

20161106_141934

20161106_141934

I got so much tension on it I was worried about stripping the threads. Called for reinforcements - dad with the propane gun! Tapped it all through from the inboard side so we could get heat directly on the offending part:

20161106_163437

20161106_163437

Once it had cooled I could get a man sized puller on it!

20161106_211217

20161106_211217

It still put up a fight but its off now. I've collected pretty much all the bits I need for it already, except the tailstock. One will turn up somewhere. The drive pulleys are both damaged but I can hopefully get them welded. The only other bit I seem to be missing is the turnbuckle arrangement that tensions the motor. I'm sure I can fabricate something for that though if I can get some measurements.

2016-11-06_10-43-59

2016-11-06_10-43-59  20161103_184126

20161103_184126 The Drive centre was firmly rusted in. Progressively bigger hammers took care of that. I then set about removing the spindle. After much lump hammer action, it was all moving apart from the outboard spacer. The one that holds it all in! I drilled and tapped the two existing holes in it to get a puller on it:

20161106_141934

20161106_141934 I got so much tension on it I was worried about stripping the threads. Called for reinforcements - dad with the propane gun! Tapped it all through from the inboard side so we could get heat directly on the offending part:

20161106_163437

20161106_163437Once it had cooled I could get a man sized puller on it!

20161106_211217

20161106_211217 It still put up a fight but its off now. I've collected pretty much all the bits I need for it already, except the tailstock. One will turn up somewhere. The drive pulleys are both damaged but I can hopefully get them welded. The only other bit I seem to be missing is the turnbuckle arrangement that tensions the motor. I'm sure I can fabricate something for that though if I can get some measurements.