I am going to start a new TV bench for my home cinema, and i am currently at the plaaning stage.

the design looks something simple, like this:

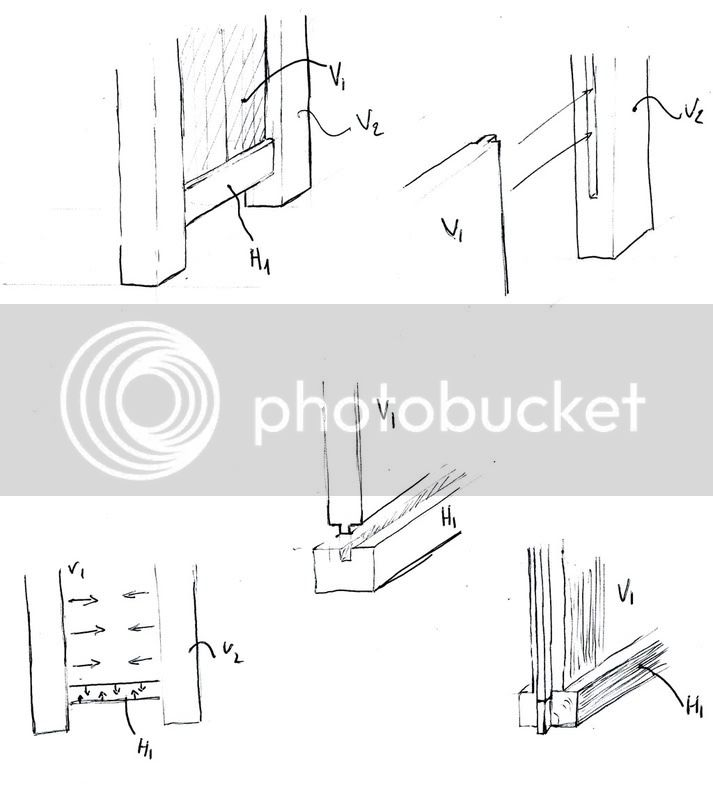

i am having doubts on the sides though, on the joinery, more specifically.

the sides are like this:

my question relates to the shrinkage of the wood, the vertical panel (v1) will shrink in the horizontal direction, but the horizontal bar at the bottom (H1) will stop this from happening. i am worried that this is a receipe for trouble and that gaps will appear between the side panel (V1) and the corner posts (v2) (which are neatly joined)

comments ?

the design looks something simple, like this:

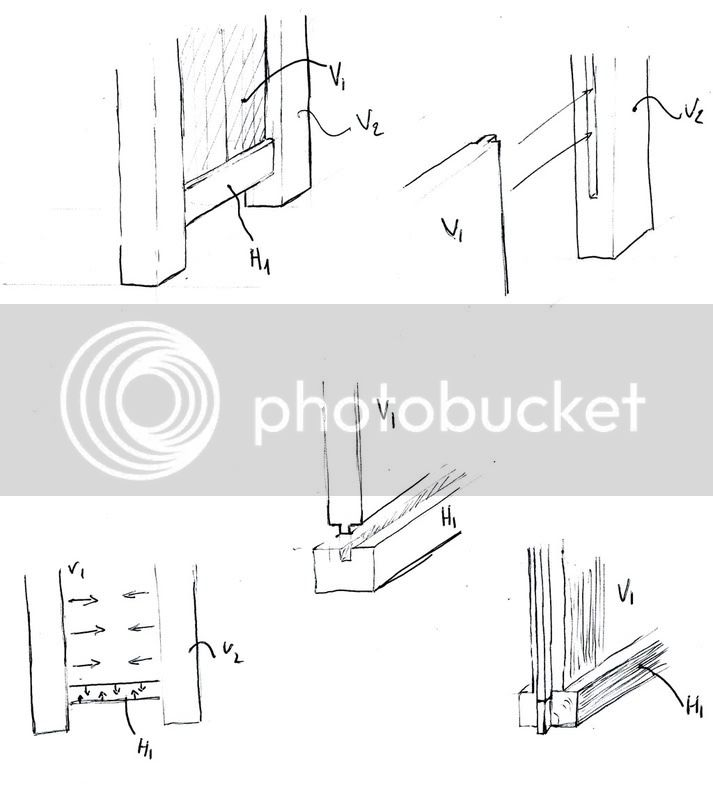

i am having doubts on the sides though, on the joinery, more specifically.

the sides are like this:

my question relates to the shrinkage of the wood, the vertical panel (v1) will shrink in the horizontal direction, but the horizontal bar at the bottom (H1) will stop this from happening. i am worried that this is a receipe for trouble and that gaps will appear between the side panel (V1) and the corner posts (v2) (which are neatly joined)

comments ?