Hi all,

I agreed to make my work mates son a toy farm for his birthday. I use to have one when i was a nipper so dragged it out from the attic.

I must have smashed the fence out at some point, so the plan was to make this one a lot more hardwearing- Cue massive over engineering :lol:

The cupboard its got to fit in is 1200 ish x 600 ish so i'm a little restricted for size. The basic plan is 2 pieces of 18mm mdf for the base and some straw and grass coloured carpets for the sides.

A picture speaks a thousand words so heres some so far of progress.

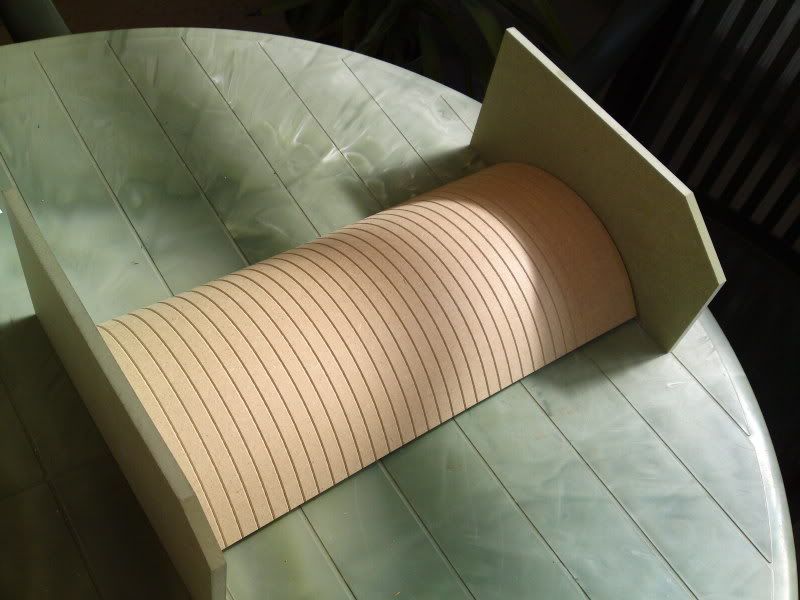

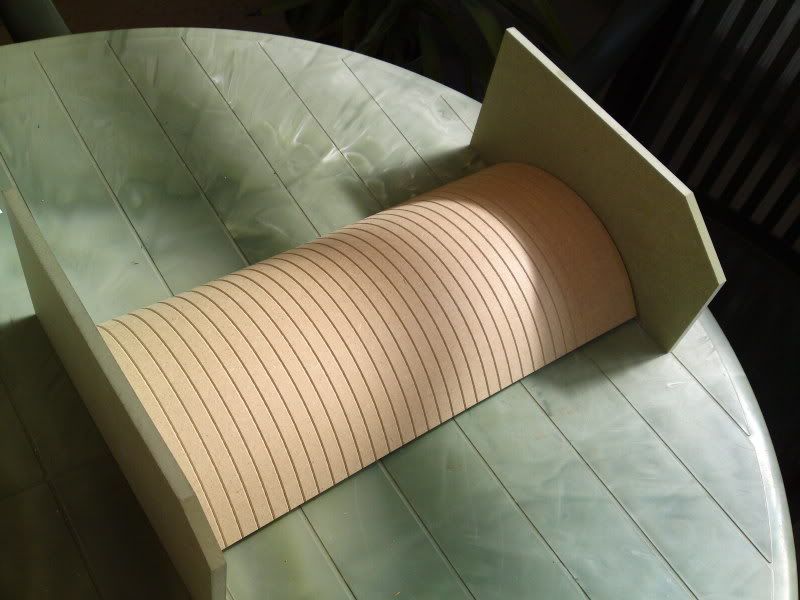

Flexi mdf for the roof

glued on some ends to hide the grooves

The glue started letting go a bit, so i took it home in the conservatory to cook.

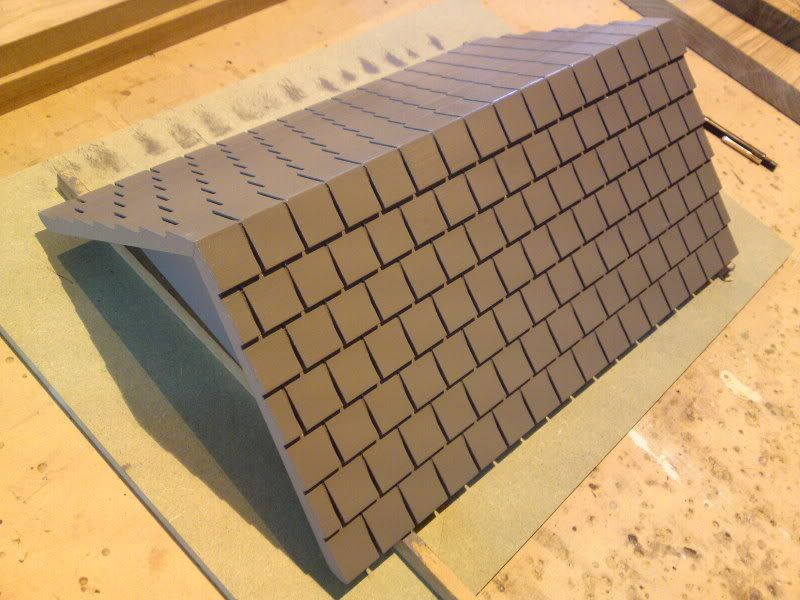

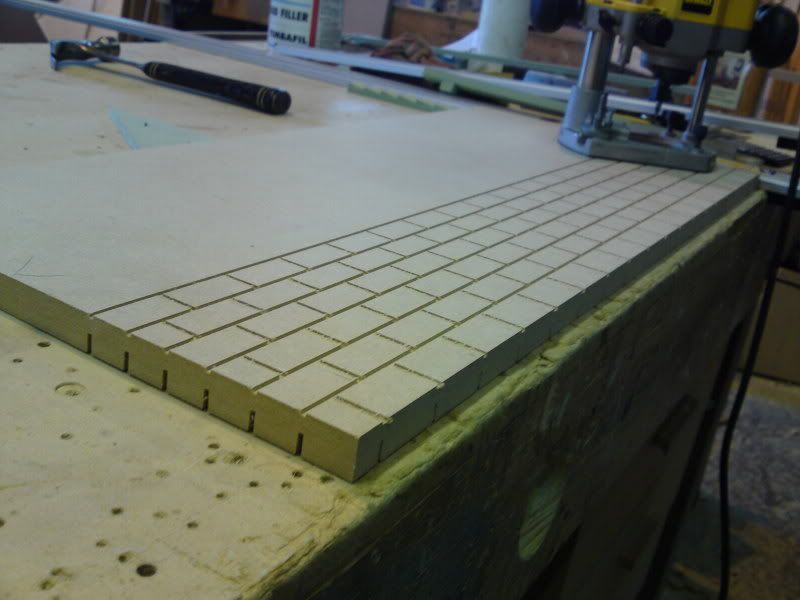

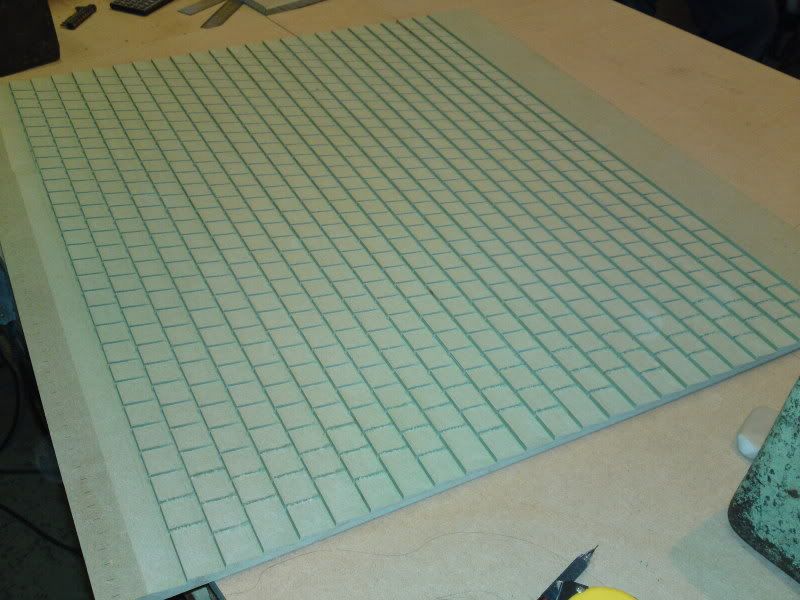

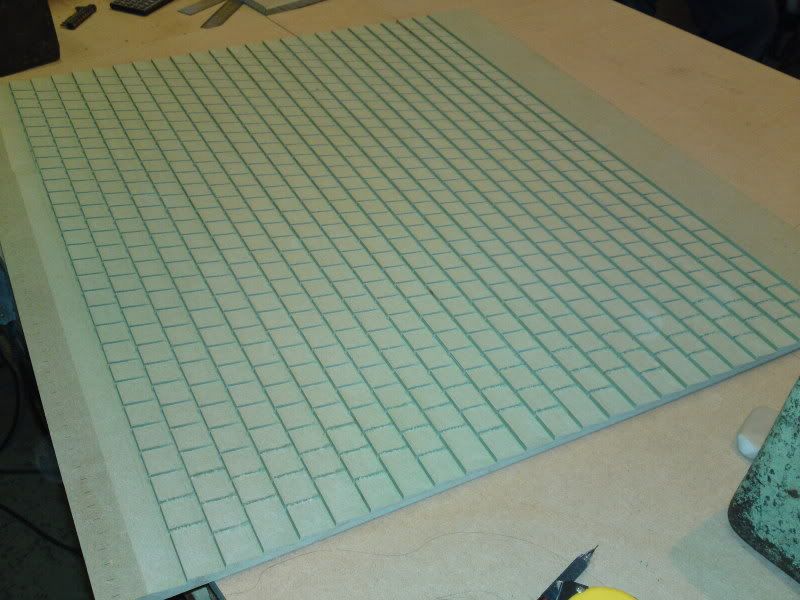

The farm house was next on the list. I wanted to make it a little more realistic then my paper covered one and had the gormless idea of routing a slate roof.

I so wish i had a cnc machine :!: 4 hours later and i had finally finished

Now i had the roof sorted i could work out what size to make the house. For this i just used 12mm mdf screwed together.

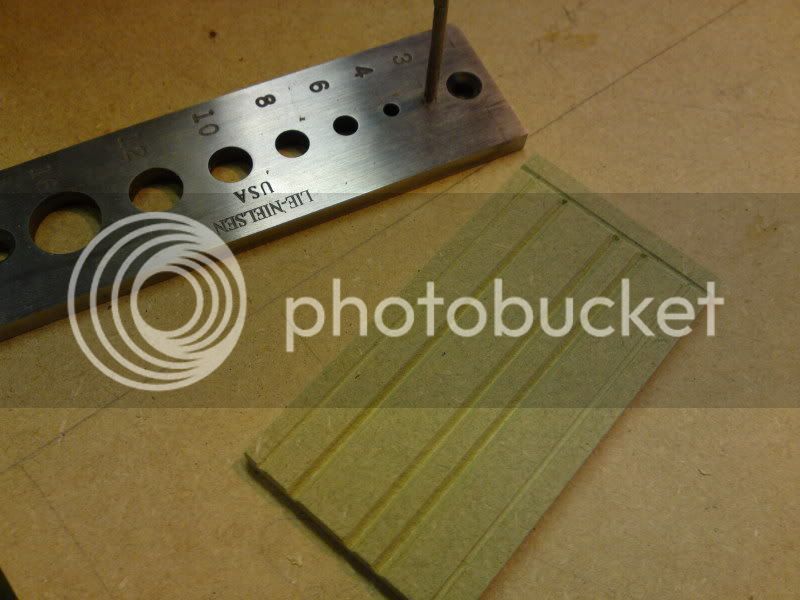

This is the jig i used for making the windows

It was using a 60 degree v groove cutter and bush, piercing right through 6mm mdf.

At this point i'm already regretting agreeing to make the thing. Its gonna take ruddy ages

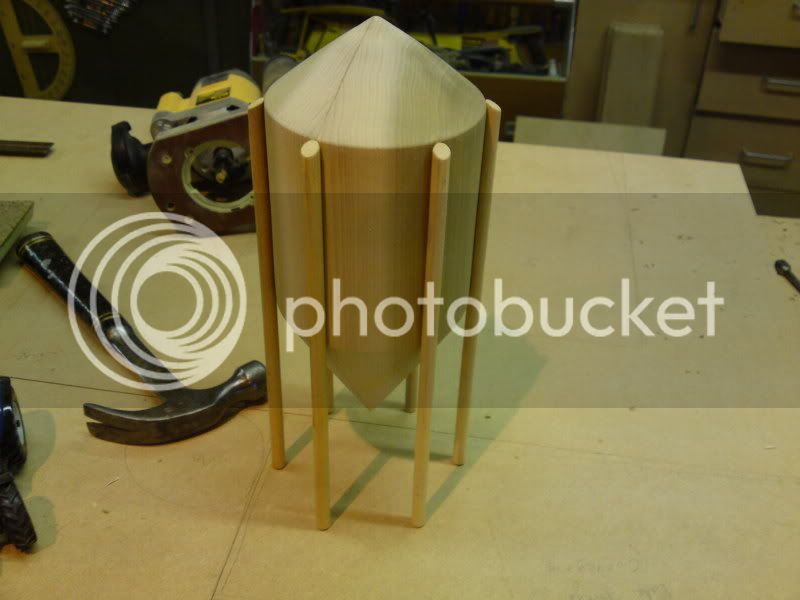

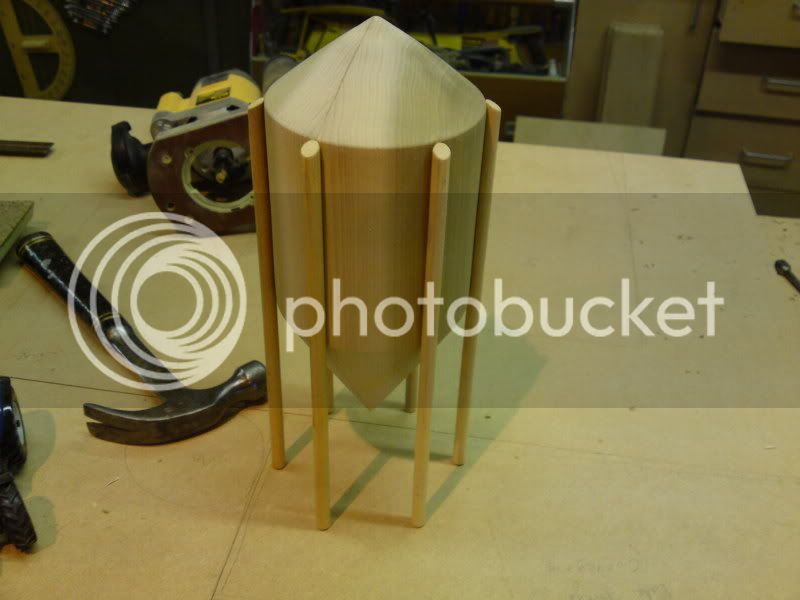

This is meant to be a silo (second attempt) I thought i'd glued up some tulip wood, only to find when i started turning it was ruddy idigbo. I had chunks flying off everywhere ](*,) I so badly dislike that stuff. His boy helped me nail on the dowel legs- Lets just say im glad he's only got a small hammer :lol:

I've got a oak cupboard i'm meant to be making for myself, but doing this is just eating up my hours :roll: His boys been over a few times and twigged onto what i'm doing. 'Simon. why have you got my tractor? That looks like a shed Simon' etc etc Gives me a bit more encouragement to get going.

I tend to start a job, lose interest half way through (usually when it gets to the painting stage :lol: ) so am determined to see this one right through with no big long breaks........

well maybe

This is where i'm at so far. Done a little more painting than the pictures show, will update when i do a little more.

Cheers

Simon

I agreed to make my work mates son a toy farm for his birthday. I use to have one when i was a nipper so dragged it out from the attic.

I must have smashed the fence out at some point, so the plan was to make this one a lot more hardwearing- Cue massive over engineering :lol:

The cupboard its got to fit in is 1200 ish x 600 ish so i'm a little restricted for size. The basic plan is 2 pieces of 18mm mdf for the base and some straw and grass coloured carpets for the sides.

A picture speaks a thousand words so heres some so far of progress.

Flexi mdf for the roof

glued on some ends to hide the grooves

The glue started letting go a bit, so i took it home in the conservatory to cook.

The farm house was next on the list. I wanted to make it a little more realistic then my paper covered one and had the gormless idea of routing a slate roof.

I so wish i had a cnc machine :!: 4 hours later and i had finally finished

Now i had the roof sorted i could work out what size to make the house. For this i just used 12mm mdf screwed together.

This is the jig i used for making the windows

It was using a 60 degree v groove cutter and bush, piercing right through 6mm mdf.

At this point i'm already regretting agreeing to make the thing. Its gonna take ruddy ages

This is meant to be a silo (second attempt) I thought i'd glued up some tulip wood, only to find when i started turning it was ruddy idigbo. I had chunks flying off everywhere ](*,) I so badly dislike that stuff. His boy helped me nail on the dowel legs- Lets just say im glad he's only got a small hammer :lol:

I've got a oak cupboard i'm meant to be making for myself, but doing this is just eating up my hours :roll: His boys been over a few times and twigged onto what i'm doing. 'Simon. why have you got my tractor? That looks like a shed Simon' etc etc Gives me a bit more encouragement to get going.

I tend to start a job, lose interest half way through (usually when it gets to the painting stage :lol: ) so am determined to see this one right through with no big long breaks........

well maybe

This is where i'm at so far. Done a little more painting than the pictures show, will update when i do a little more.

Cheers

Simon