Best b/e chisel for cabinetmaking benchwork is the Ashley Iles, but it's not a 'site' chisel. Best for site work probably Marples unbreakable plastic handled jobby.

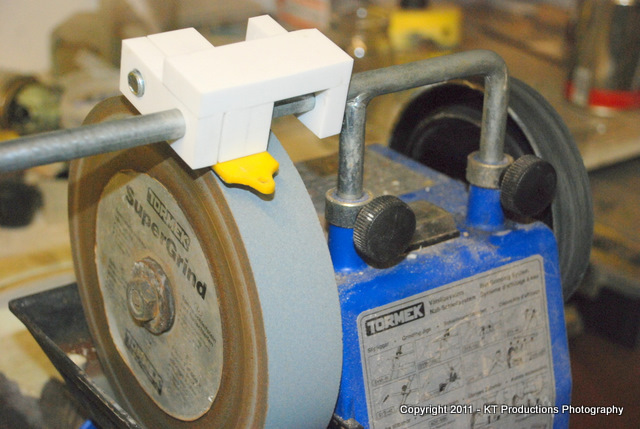

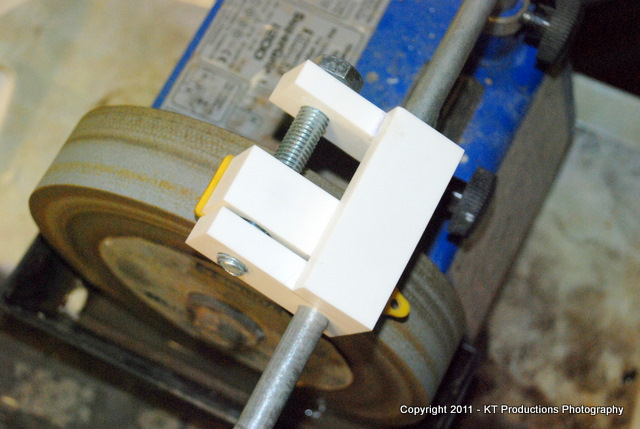

The Tormek is a super machine, but the soft, friable wheels do wear very quickly. There are two possible approaches, both with pros and cons.

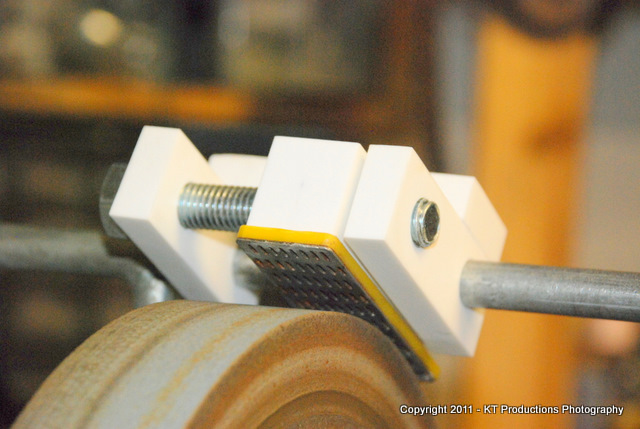

The first is to dress the wheel as stated above. You end up with a true surface, but the act of trueing takes off quite a bit of abrasive, which accelerates wheel wear, and Tormek replacement wheels are not cheap. Don't forget to move the job side-to-side to even out wear on the wheel during grinding, too.

The second approach is to become more freehand in your grinding technique. Just offer the edge to the wheel, keep it moving sideways, and bias grinding to where the wheel is least worn. Check progress of the partially-ground edge frequently with a small square and bevel angle gauge (mine is a piece of cardboard with notches at different bevel angles cut in the edges) until you have what you need. The advantages of this approach are speed (no jigs to set up) and slower wheel wear (all wear happens during grinding, none is lost during trueing). The downside is that you need to develop a bit of 'feel' for grinding to get a really straight edge, though for most chisels and cambered plane irons, you don't really need edges ground dead true anyway. (I've been using this freehand approach for years, and don't have any problems getting tool edges as straight and square as I need them.)

The two approaches could be combined by using freehand methods for most grinding, and trueing the wheel up before using a jigged set-up for anything that absolutely has to be straight and dead square (rebate plane irons, perhaps?).