gidon

Established Member

Well you know that you can't leave a woodworking show empty handed and I didn't really need any more Bessey clamps  (did still pick up with of their mitre clamps though

(did still pick up with of their mitre clamps though  ) well ....

) well ....

I've never been 100% happy with grinding my primary bevels - I use a coarse DMT Duosharp or my bench grinder. The diamond stone is slow and I'm always a little nervous using the bench grinder with my better metal. I planned to try one of the Norton 3x stones but I saw a very cheap Tormek clone on the Scheppach stand at the Yandles show for £90 - the Tiger 2000s. Decided to give it a go.

Unfortunately my model was faulty - a phonecall to NMA and they kindly offered to swap it out. I decided to add some money for the German built Tiger 2500 (£159) - both the Tiger 2000 and the 2000s are made in China. This arrived next day and the 2000s was collected. Very efficient service from NMA - well impressed.

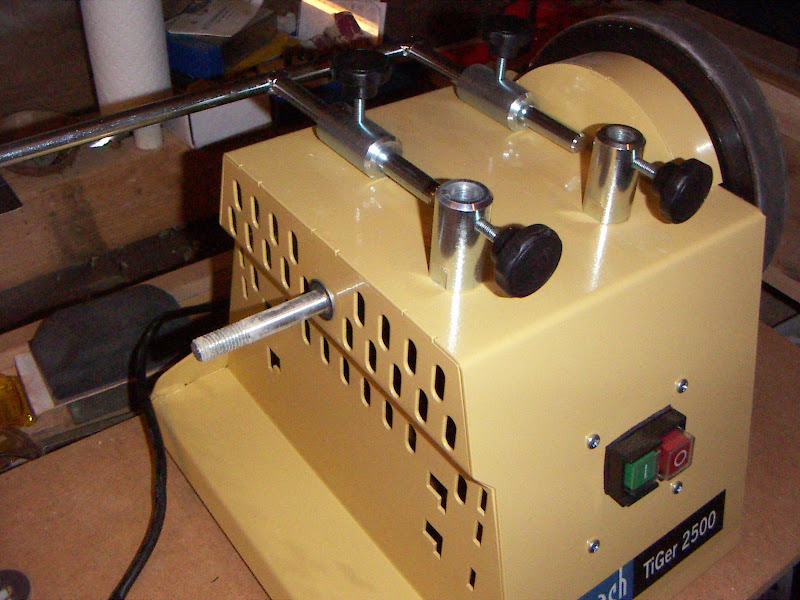

The Tiger 2500 was in another league all together (and £70 more expensive - typically it appears to be sold in the US as the Grizzly 10010 for $170 - arghh!!). Very well built with a larger 10" stone and a continuously rated motor.

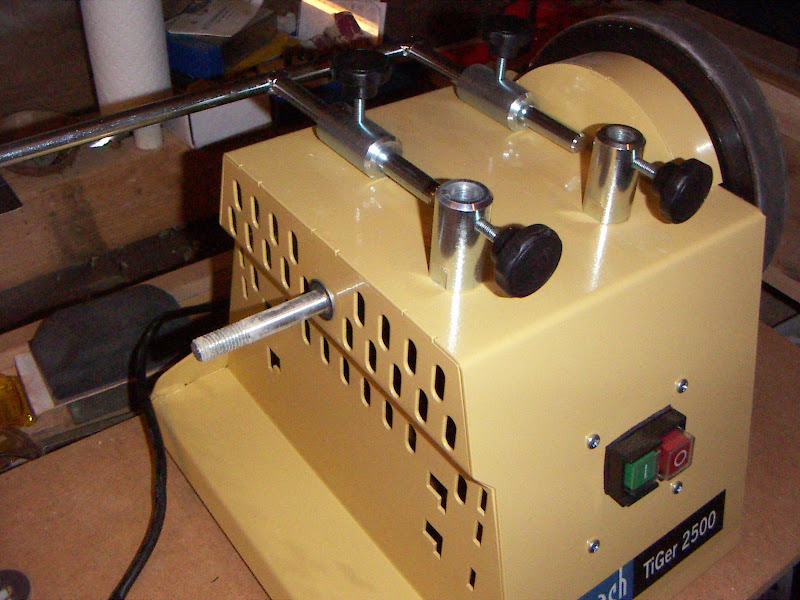

Tiger 2500:

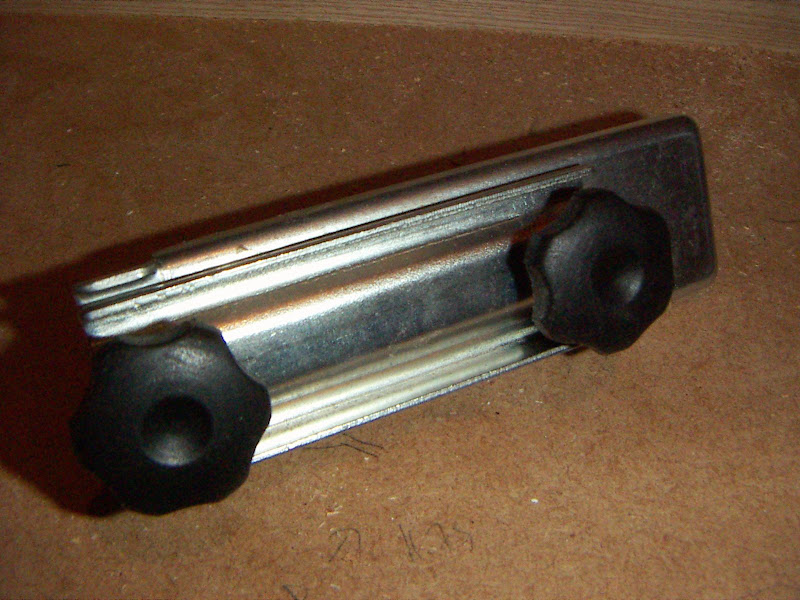

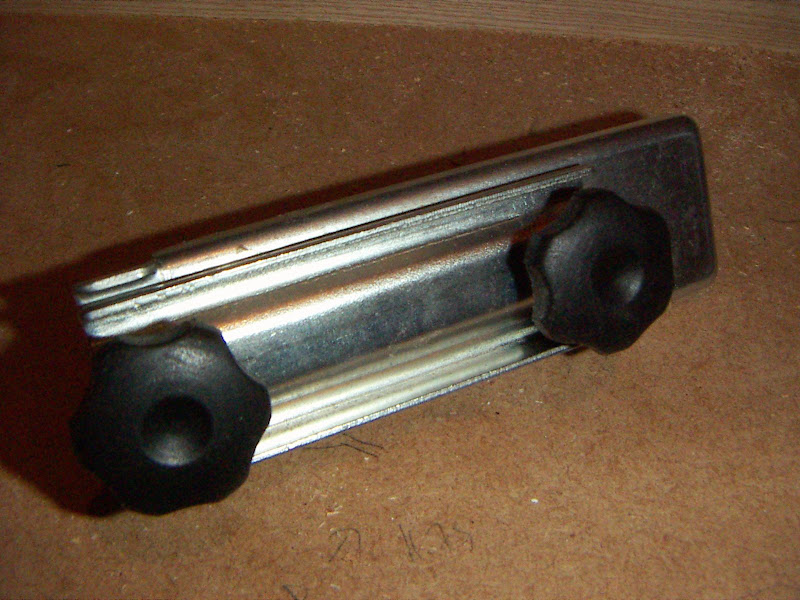

Scheppach square jig:

I wasn't having much luck though because although the support bar was square to the stone in the horizontal position it wasn't in the vertical position! So even if I paid another £40 for a truing tool it would always be off in the other position. I did consider fiddling about with the bushes to get things right but wasn't keen - felt this should work out of the box. Another phone call to NMA and reluctantly I returned the grinder to NMA for a refund (again excellent service from NMA). I did want to try another Tiger 2500 but couldn't face any more bad luck. It's a shame because although still pricey it's represents very good value against the Tormek (at about £100 less). I will do a few comparisons in the review of the Tormek below ...

I was a bit gutted - although a luxury I quite like the simplicity of grinding primary bevels on a wet grinder. No sparks , quiet, lots of fun jigs for the gadgeteer in me. So I considered alternatives. Axminster had 10% off so looked at the Jet grinder. Seems to have gone up in price - it's not much cheaper than a Tormek anymore. Can you see where this is going ?

?

I liked some of the features on the Jet but also read a lot of bad reports on the Amazon.com reviews. So somehow I persuaded myself to look at the Tormeks! With the 10% off the 2006 model was £90 more than the Tiger 2500. But by the time you added in the extra features of the T7 that proved better value. So onto the review ...

I'll start off by saying the T7 is complete overkill for me. It's a luxury pure and simple. There is no way I can justify spending this much just to grind a primary bevel! That said it's fantastic - it oozes quality. Plus I've always been quite fond of the Tormek story - as I write I've just had a personal response from the Tormek creator Torgny Jansson - that is impressive! How many times can you speak with a person who invented and continuously develops a tool like this? That attracts me to the Veritas and LN range too (unfortunately ).

).

The T7 is essentially the same as the later models of the 2006 - here are the differences (courtesy of Jeff Farris on SMC):

I knew I'd end up getting the extras that come with the T7 so with the 10% off I was betting off paying it up front. I also ordered the hand tool kit. I didn't realise this until after I ordered it but you get a free Swedish (Mora) chef's knife if you order these together worth 70 euros - I'll let you know what it's like.

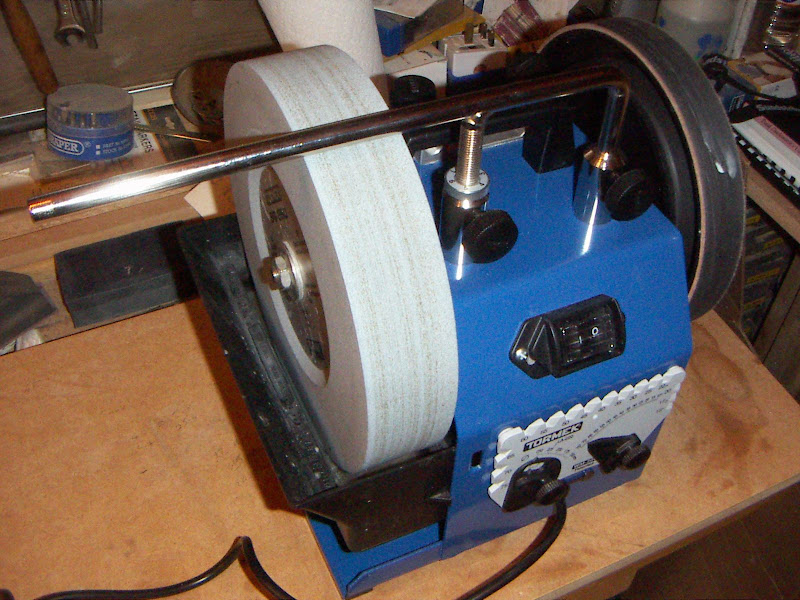

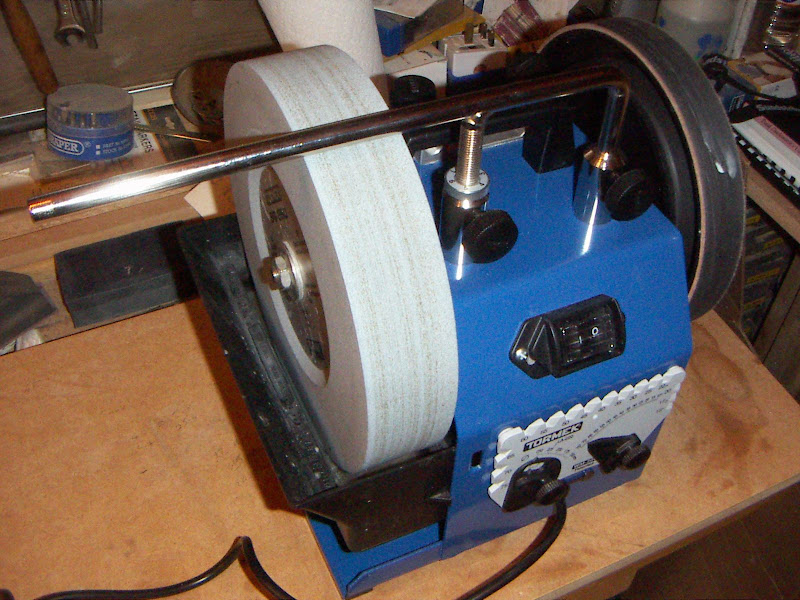

T-7 grinder:

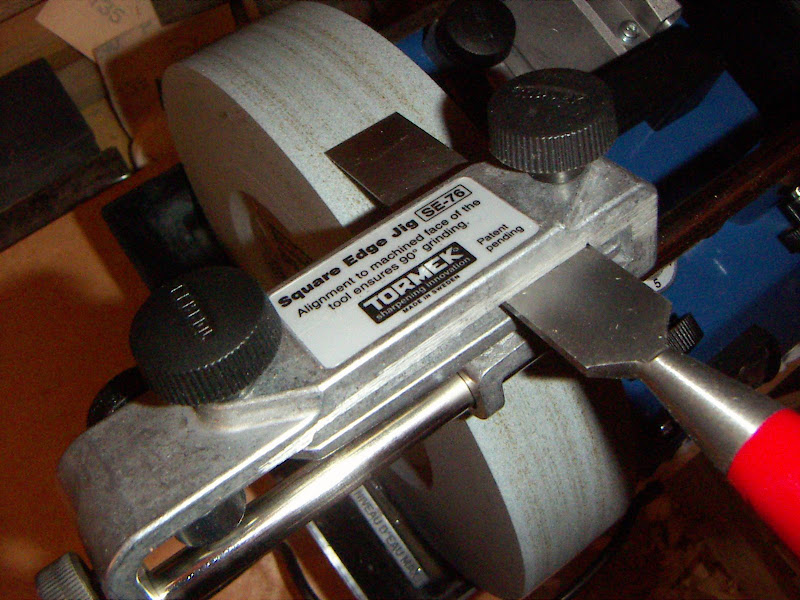

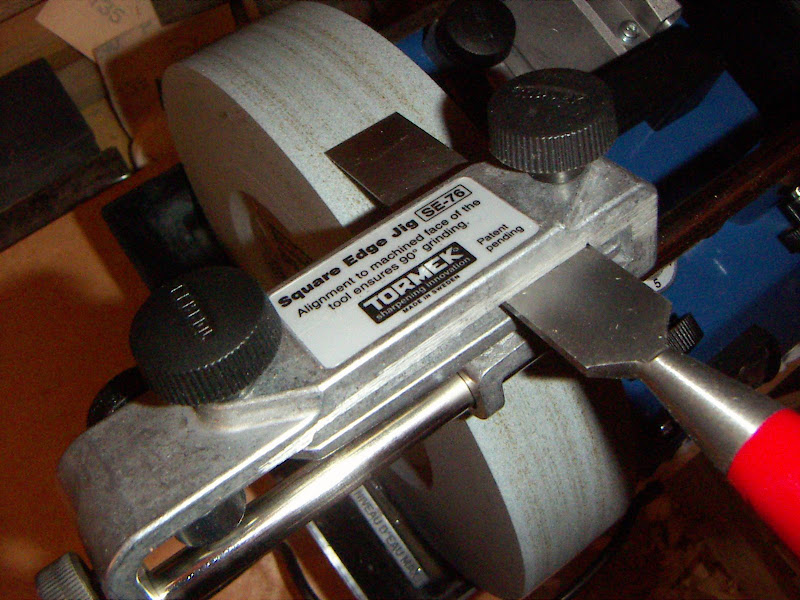

Chisel setup in new SE-76 jig:

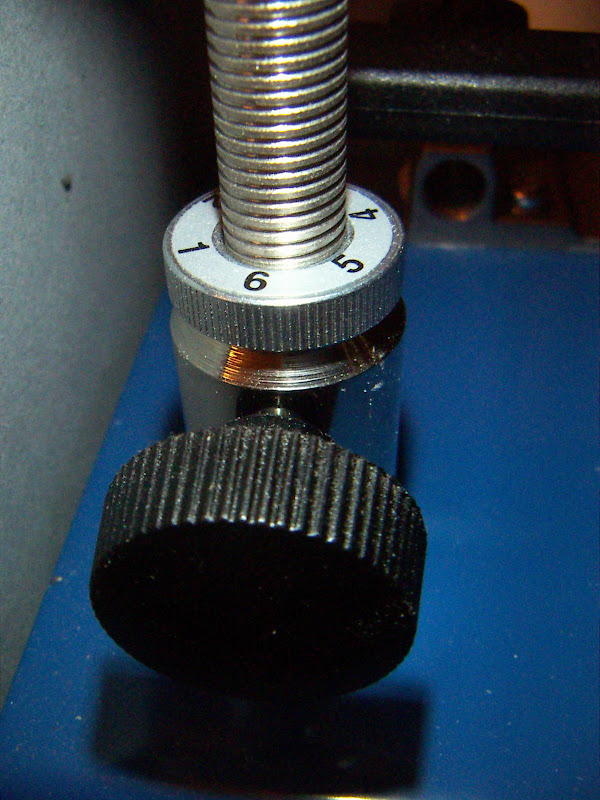

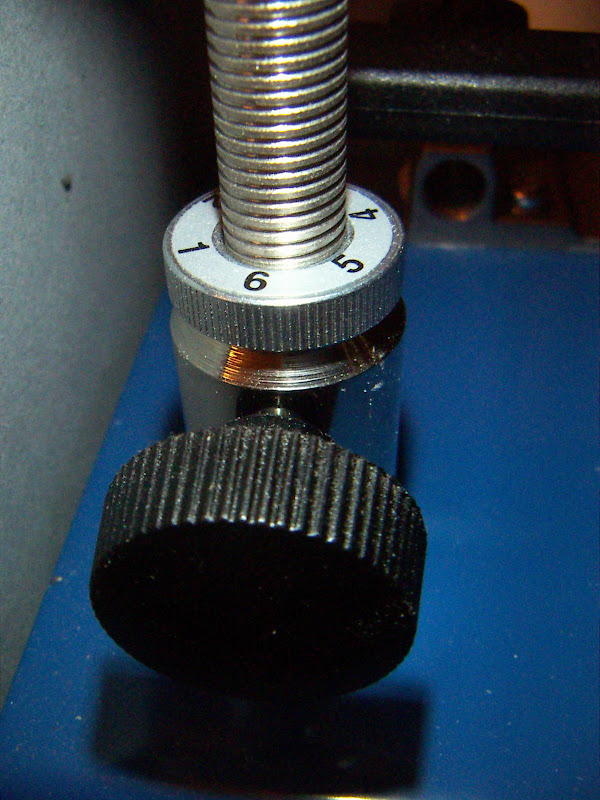

Micro-adjust (patented so not available on the clones):

T-7 included accessories:

Hand tool kit:

Now this is a well built machine - probably about the most carefully engineered machine in my workshop. The jigs are also impressive - all appear to made in Sweden like the machine itself. All carefully thought out and with instructions that put the Scheppach to shame. Of course you can download and use the Tormek manual and the Tormek jigs work on the Scheppach and Jet machines - all have a 12mm support bar - so this is sort of a moot point. Checking everything all seemed well - the support bar is square to the stone in both positions.

I was ready to grind my first chisels in minutes after letting the wheel soak up a fair bit of water. The new SE-76 jig is very nice - it references from the back the blade when clamping to ensure a square edge. The first thing I noticed was the stone on the Tormek cut quicker than on the Scheppach, plus I could put all my weight and not stall the motor or notice any significant slow down - which really speeds up grinding. The angle guide is so much better than the one that comes with the Scheppach - again you can purchase it seperately. It can be adjusted to work with any wheel size including the honing wheel. It's also much easier to use. The Scheppach one confused me - that could just be me!

Straight off the coarsely graded stone I went to my bench stones and went through my normal honing procedure in about 1 minute. It's very easy to freehand hone the nice big bevel if you feel so inclined and both freehand and with my Veritas MKII jig I had a razer sharp edge in a minute or two.

I'm going to come back to this review if there's any interest - after I've played around with it more and I'm interested to compare a complete edge created on the Tormek against my benchstones methods. Sorry Adam - I am one of this people that spends far too long sharpening and not enough time woodworking . What can I - I enjoy it - I found it such a revelation when I got my first truly sharp edge it's engaged me ever since!

. What can I - I enjoy it - I found it such a revelation when I got my first truly sharp edge it's engaged me ever since!

I realise I've done this Tormek thing in reverse formation - I think most people buy one first then try other methods later on. I don't regret for a minute buying one after I've been woodworking for 10 years - I've learnt a lot about sharpening in that time.

It is very expensive for what it is but it should last me for a long time (so gutted I missed the free stones for life offer ). Never has the addage you get what you pay for been more accurate. But that's not to say you couldn't get excellent results using the Scheppach Tiger 2500 (I'll reserve judgement on the 2000s) - I'm pretty sure I was just unlucky.

). Never has the addage you get what you pay for been more accurate. But that's not to say you couldn't get excellent results using the Scheppach Tiger 2500 (I'll reserve judgement on the 2000s) - I'm pretty sure I was just unlucky.

I know people criticie the Tormek for being slow but they can't have tried grinding on bench stones!

Cheers

Gidon

I've never been 100% happy with grinding my primary bevels - I use a coarse DMT Duosharp or my bench grinder. The diamond stone is slow and I'm always a little nervous using the bench grinder with my better metal. I planned to try one of the Norton 3x stones but I saw a very cheap Tormek clone on the Scheppach stand at the Yandles show for £90 - the Tiger 2000s. Decided to give it a go.

Unfortunately my model was faulty - a phonecall to NMA and they kindly offered to swap it out. I decided to add some money for the German built Tiger 2500 (£159) - both the Tiger 2000 and the 2000s are made in China. This arrived next day and the 2000s was collected. Very efficient service from NMA - well impressed.

The Tiger 2500 was in another league all together (and £70 more expensive - typically it appears to be sold in the US as the Grizzly 10010 for $170 - arghh!!). Very well built with a larger 10" stone and a continuously rated motor.

Tiger 2500:

Scheppach square jig:

I wasn't having much luck though because although the support bar was square to the stone in the horizontal position it wasn't in the vertical position! So even if I paid another £40 for a truing tool it would always be off in the other position. I did consider fiddling about with the bushes to get things right but wasn't keen - felt this should work out of the box. Another phone call to NMA and reluctantly I returned the grinder to NMA for a refund (again excellent service from NMA). I did want to try another Tiger 2500 but couldn't face any more bad luck. It's a shame because although still pricey it's represents very good value against the Tormek (at about £100 less). I will do a few comparisons in the review of the Tormek below ...

I was a bit gutted - although a luxury I quite like the simplicity of grinding primary bevels on a wet grinder. No sparks , quiet, lots of fun jigs for the gadgeteer in me. So I considered alternatives. Axminster had 10% off so looked at the Jet grinder. Seems to have gone up in price - it's not much cheaper than a Tormek anymore. Can you see where this is going

I liked some of the features on the Jet but also read a lot of bad reports on the Amazon.com reviews. So somehow I persuaded myself to look at the Tormeks! With the 10% off the 2006 model was £90 more than the Tiger 2500. But by the time you added in the extra features of the T7 that proved better value. So onto the review ...

I'll start off by saying the T7 is complete overkill for me. It's a luxury pure and simple. There is no way I can justify spending this much just to grind a primary bevel! That said it's fantastic - it oozes quality. Plus I've always been quite fond of the Tormek story - as I write I've just had a personal response from the Tormek creator Torgny Jansson - that is impressive! How many times can you speak with a person who invented and continuously develops a tool like this? That attracts me to the Veritas and LN range too (unfortunately

The T7 is essentially the same as the later models of the 2006 - here are the differences (courtesy of Jeff Farris on SMC):

The differences between the 2006 and the T-7 are as follows:

T-7 includes the TT-50 Truing Tool as a standard feature -- the 2006 does not.

T-7 includes the SP-650 Stone Grader as a standard feature -- the 2006 does not.

T-7 includes the new SE-76 Square Edge Jig. The 2006 includes the old design SVH-60 Straight Edge Jig.

T-7 Interior packaging is designed as a storage tray.

Several other features of the T-7 would be found on late production 2006 models. Those would be improved motor isolation, cast and machined horizontal base, stainless steel shaft and stone hardware, and square cut threads on the Universal Support.

I knew I'd end up getting the extras that come with the T7 so with the 10% off I was betting off paying it up front. I also ordered the hand tool kit. I didn't realise this until after I ordered it but you get a free Swedish (Mora) chef's knife if you order these together worth 70 euros - I'll let you know what it's like.

T-7 grinder:

Chisel setup in new SE-76 jig:

Micro-adjust (patented so not available on the clones):

T-7 included accessories:

Hand tool kit:

Now this is a well built machine - probably about the most carefully engineered machine in my workshop. The jigs are also impressive - all appear to made in Sweden like the machine itself. All carefully thought out and with instructions that put the Scheppach to shame. Of course you can download and use the Tormek manual and the Tormek jigs work on the Scheppach and Jet machines - all have a 12mm support bar - so this is sort of a moot point. Checking everything all seemed well - the support bar is square to the stone in both positions.

I was ready to grind my first chisels in minutes after letting the wheel soak up a fair bit of water. The new SE-76 jig is very nice - it references from the back the blade when clamping to ensure a square edge. The first thing I noticed was the stone on the Tormek cut quicker than on the Scheppach, plus I could put all my weight and not stall the motor or notice any significant slow down - which really speeds up grinding. The angle guide is so much better than the one that comes with the Scheppach - again you can purchase it seperately. It can be adjusted to work with any wheel size including the honing wheel. It's also much easier to use. The Scheppach one confused me - that could just be me!

Straight off the coarsely graded stone I went to my bench stones and went through my normal honing procedure in about 1 minute. It's very easy to freehand hone the nice big bevel if you feel so inclined and both freehand and with my Veritas MKII jig I had a razer sharp edge in a minute or two.

I'm going to come back to this review if there's any interest - after I've played around with it more and I'm interested to compare a complete edge created on the Tormek against my benchstones methods. Sorry Adam - I am one of this people that spends far too long sharpening and not enough time woodworking

I realise I've done this Tormek thing in reverse formation - I think most people buy one first then try other methods later on. I don't regret for a minute buying one after I've been woodworking for 10 years - I've learnt a lot about sharpening in that time.

It is very expensive for what it is but it should last me for a long time (so gutted I missed the free stones for life offer

I know people criticie the Tormek for being slow but they can't have tried grinding on bench stones!

Cheers

Gidon