Just wondered what the general concensus was.

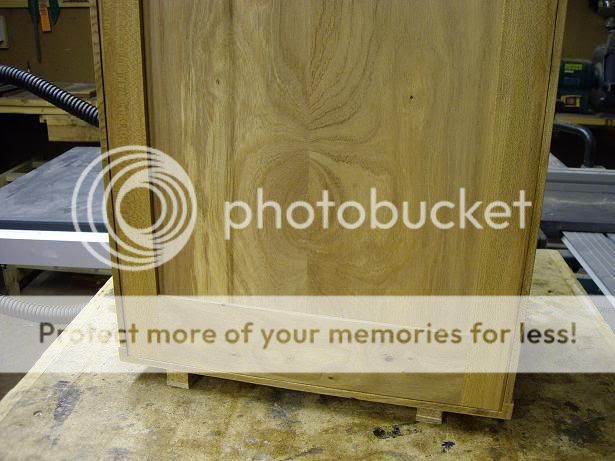

I've made numerous tables and unit tops and generally speaking I tend not to bother biscuiting the edges. Just a good plane and some decent glue and clamp for 24 hours.

Who biscuits and who doesnt?

Just wondered

Steve

I've made numerous tables and unit tops and generally speaking I tend not to bother biscuiting the edges. Just a good plane and some decent glue and clamp for 24 hours.

Who biscuits and who doesnt?

Just wondered

Steve