devonwoody

Established Member

I know what you mean C. but I have been getting away with this sort of thing the past five years, watch my avatar (left hand side) and there some real shockers.

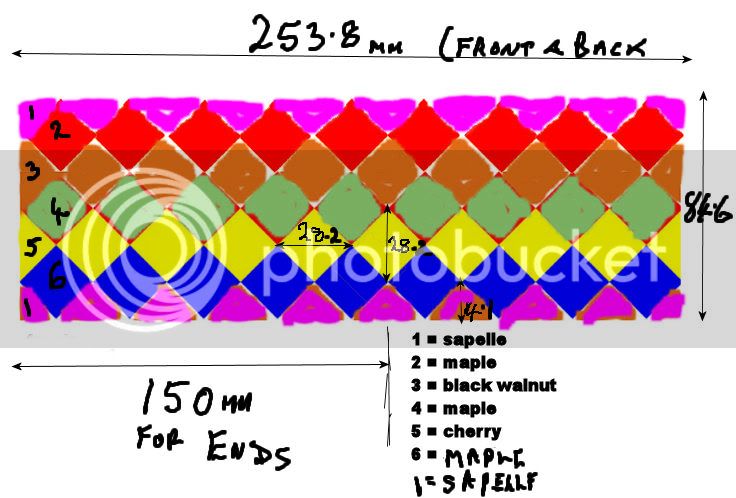

I went out to the W/S around 5pm and thought I would make a start, pulled out some different timbers and my head started swimming trying to work out the colour co ordination of the harlequin patterns. Had to come in and do a drawing and print out as per this.

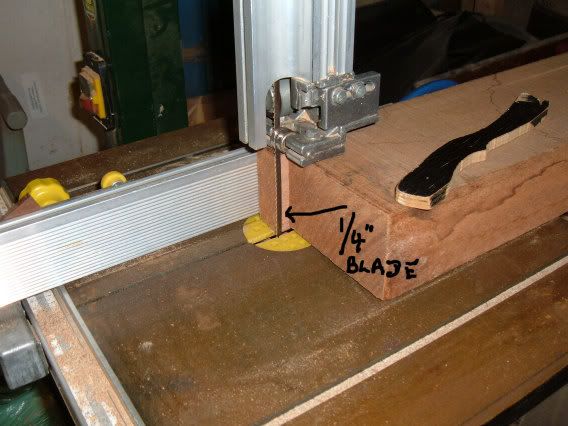

This time I am going to make the blocks around 25 mm thick and then resaw to half thickness to double up the front and ends.

I went out to the W/S around 5pm and thought I would make a start, pulled out some different timbers and my head started swimming trying to work out the colour co ordination of the harlequin patterns. Had to come in and do a drawing and print out as per this.

This time I am going to make the blocks around 25 mm thick and then resaw to half thickness to double up the front and ends.