As a result of not really finding what I wanted in the way of thumbscrews, I have somewhat embarked on a journey into engineering. Yes I know this is a woodworking forum, but it is related and hopefully of interest to some members.

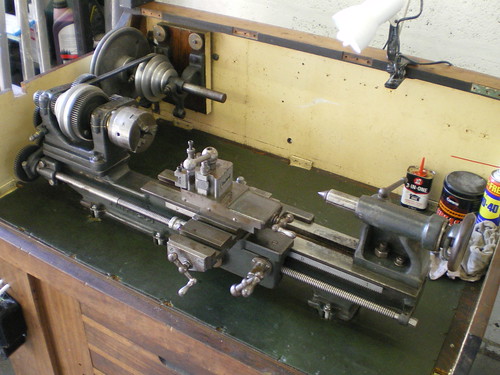

Since the last round of posts on this thread I have acquired a metalworking lathe, complete with a collection of tooling, from a fellow forum member;

After a considerable amount of cleaning and setting up the machine is operational and appears to be running nicely, so I have made a start on my first items, namely brass thumbscrews.

Here is my second effort (I'll keep the first one to myself - lets just say it was a valuable learning experience!)

I'm quite pleased with it and also found the process of making it really enjoyable. Now in terms of man hours its not efficient (yet) and amortising my investment so far these currently stand as the 2 most expensive bolts I've ever handled at just over £50 each, but hey I'm on a journey.

The engineers among you will notice that the knurling is not perfect - I had real trouble getting the pattern to match up. I understood that when this happens the thing to do is reduce the diameter slightly and try again - I did this several times and never quite got there. Any tips would be greatly appreciated - I'm not an engineer so you can safely assume pretty limited knowledge on my part.

I'm now thinking about the turned metal parts I can incorporate into my furniture. I'm also thinking that I can make some small wooden parts on this machine (within reason) when the need arises.

Any comments / suggestions for improvement appreciated.

Cheers, Ed.