manxnorton

Established Member

Hi all,

Sorry if this thread is in the wrong place

Anyways, got thinking about the apple wood candle holders that cracked. :idea:

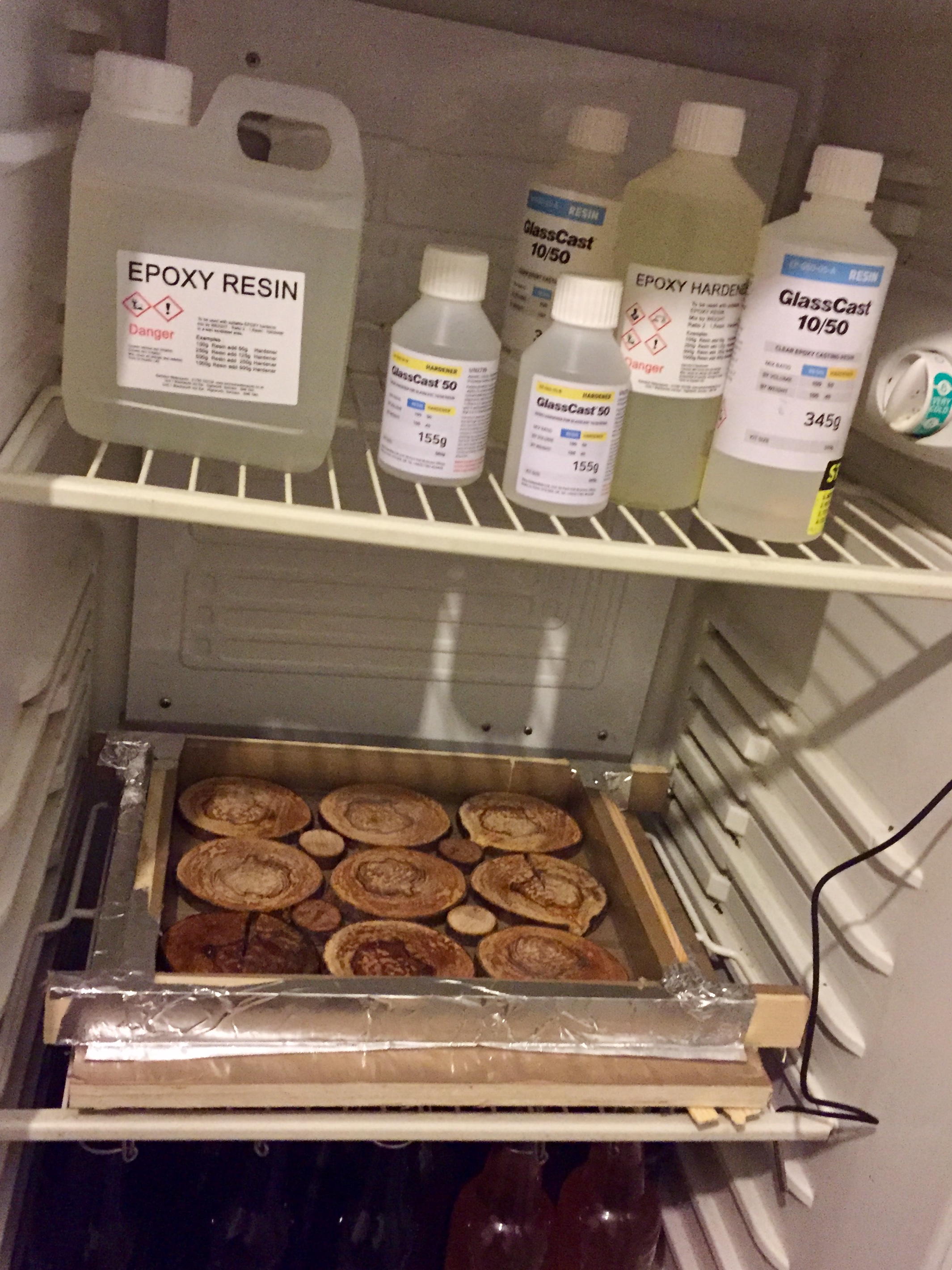

What about epoxy resin to fill the cracks.

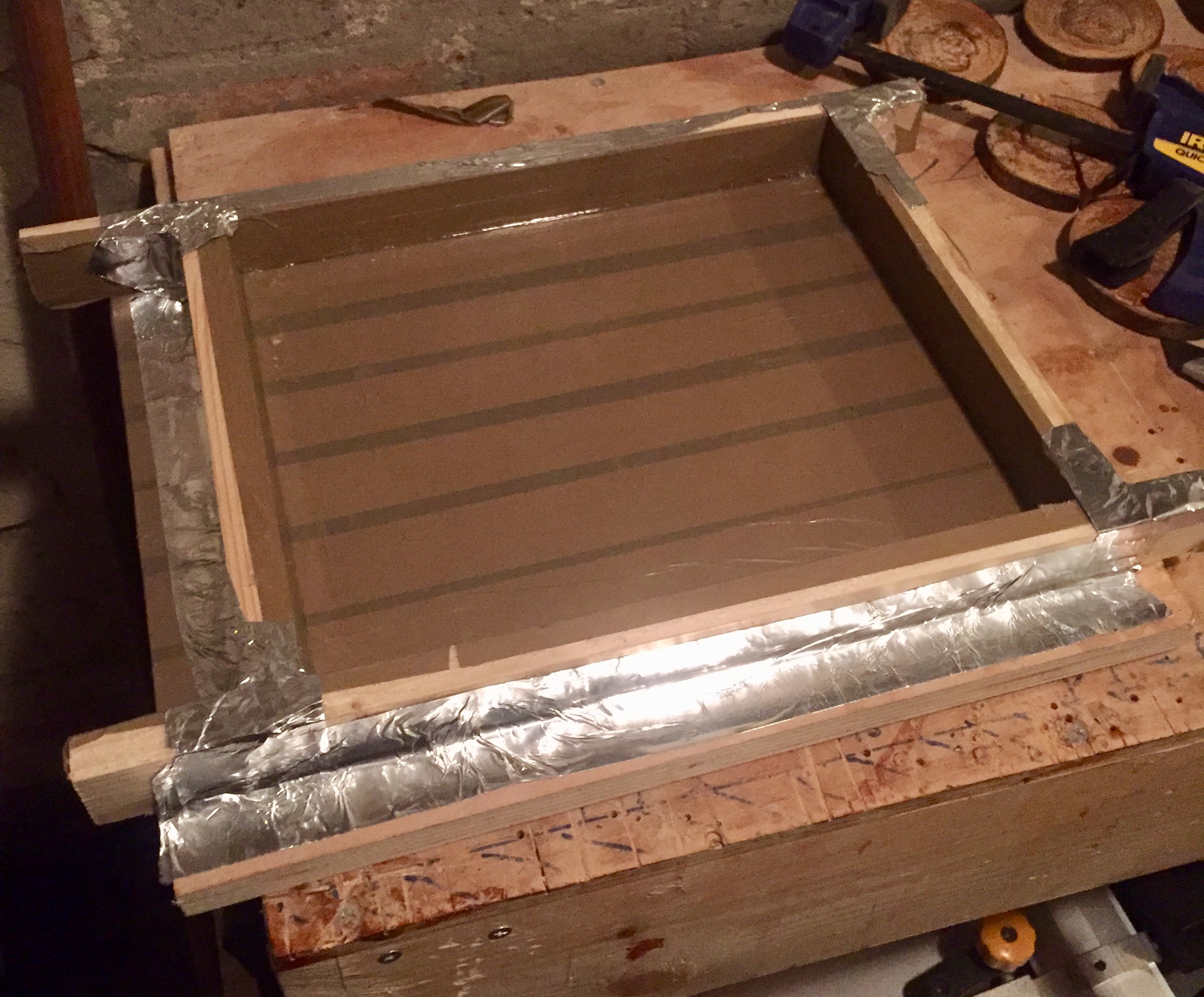

I would love to do small projects and one is a chopping board using the apple discs.

Ok got no idea the best Epoxy resin to buy in UK, and food safe, cast resin etc etc.

Any help and advice be great (links pics etc good for me!)

As you know I don't just jump in, but like to research b4 spending money for tools etc :lol:

Hours and hours on YouTube sent me crazy...so many nice projects =D> =D> =D>

Looking faeward to help, as im keen to get into this form of the hobby.

ATB

Bri

Sorry if this thread is in the wrong place

Anyways, got thinking about the apple wood candle holders that cracked. :idea:

What about epoxy resin to fill the cracks.

I would love to do small projects and one is a chopping board using the apple discs.

Ok got no idea the best Epoxy resin to buy in UK, and food safe, cast resin etc etc.

Any help and advice be great (links pics etc good for me!)

As you know I don't just jump in, but like to research b4 spending money for tools etc :lol:

Hours and hours on YouTube sent me crazy...so many nice projects =D> =D> =D>

Looking faeward to help, as im keen to get into this form of the hobby.

ATB

Bri