Hi,

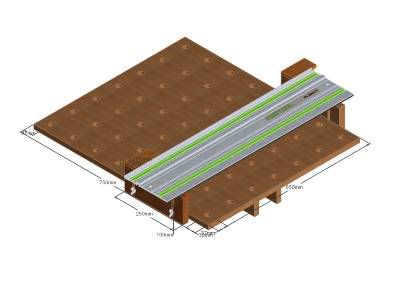

I am a beginner and so far I enjoyed doing a few projects with a jig saw, router, cordless drill and a couple hand planes. Now I reached the stage where I would like to get a good power saw and I cannot decide between an entry-level table saw (e.g. Makita MLT100, which received good comments in this forum) or a rail-guided plunge saw (e.g. Festool TS55 or Makita SP6000). I am leaning towards the plunge saw for two main reasons: space (I work in my basement in a room 3x3.5 meters...) and safety (I have the impression that with a plunge saw my fingers will be less close to the blade...).

What is your advice ? is a plunge saw really safer than a table saw ? what will I miss from not having a table saw ?

Thanks for sharing your experience and knowledge

I am a beginner and so far I enjoyed doing a few projects with a jig saw, router, cordless drill and a couple hand planes. Now I reached the stage where I would like to get a good power saw and I cannot decide between an entry-level table saw (e.g. Makita MLT100, which received good comments in this forum) or a rail-guided plunge saw (e.g. Festool TS55 or Makita SP6000). I am leaning towards the plunge saw for two main reasons: space (I work in my basement in a room 3x3.5 meters...) and safety (I have the impression that with a plunge saw my fingers will be less close to the blade...).

What is your advice ? is a plunge saw really safer than a table saw ? what will I miss from not having a table saw ?

Thanks for sharing your experience and knowledge