EdK

Established Member

Evening all

I am getting more into this wood malarky and had some questions concerning measurements etc.

I have been using a plastering level for a straight edge but know that it is probably not 100% a good idea!

I was looking at the Starrett ones mentioned in David C's book (think they are 386 ? L http://www.jwdonchin.com/Starrett/Catal ... s/386.html) but they are about £100 for a 24" one.

Then I saw the Kinex ones in the Tilgear catalogue but they mention at the bottom that they are not suitable for fine tolerance engineering or something like that... not exactly inspiring when looking for a fine tolerance tool!

I remember a Veritas one mentioned on this site (CHT maybe?) but someone said they weren't great ?

Anyway...

What is a good length to buy ?

Any recommendations ?

Also I was looking at gauges for marking and for mortise marking.

Again I am tempted by the cheap square head ones recommended in the David C book from Tilgear (couple of quid each).

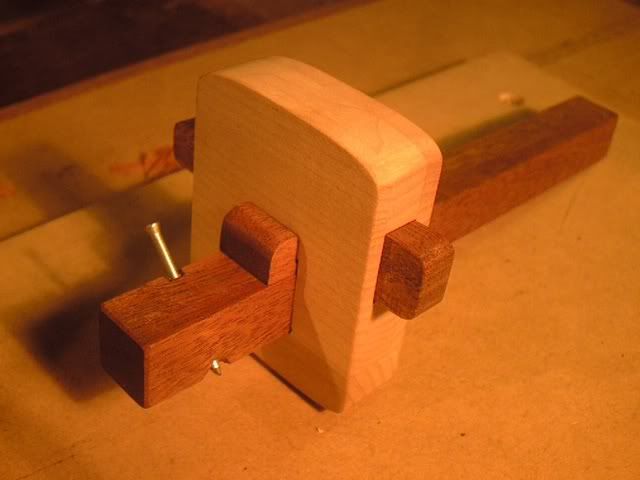

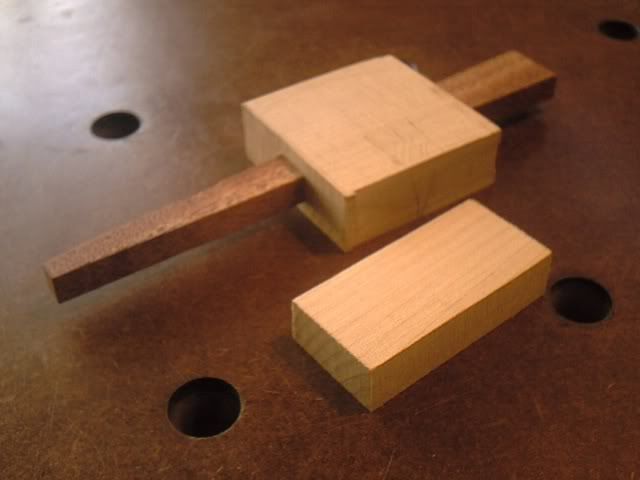

But then I saw the round wheel ones and was wondering if this was a better option?

I saw a few posted here that people have made - not sure I have the time as everything takes me ages to make as I am a newbie !

Having said that I do have a nice length of beech fished out of a skip (old door tread).

Was looking at the £6.50 mortise ones fromTilgear (Marples I think).. Any good?

So are the wheel gauges better ?

Is it better to buy a gauge with a blade or a pin ?

What is a good number of gauges to buy ?

What about number of mortise gauges to buy ?

One more thing:

Marking knives...

I made one from a piece of industrial hacksaw blade (about 30mm by 120mm) and this seems to work well. But I was wondering if the japanese ones were better ? Saw one in Tilgear for about £5...

Thanks

Ed

I am getting more into this wood malarky and had some questions concerning measurements etc.

I have been using a plastering level for a straight edge but know that it is probably not 100% a good idea!

I was looking at the Starrett ones mentioned in David C's book (think they are 386 ? L http://www.jwdonchin.com/Starrett/Catal ... s/386.html) but they are about £100 for a 24" one.

Then I saw the Kinex ones in the Tilgear catalogue but they mention at the bottom that they are not suitable for fine tolerance engineering or something like that... not exactly inspiring when looking for a fine tolerance tool!

I remember a Veritas one mentioned on this site (CHT maybe?) but someone said they weren't great ?

Anyway...

What is a good length to buy ?

Any recommendations ?

Also I was looking at gauges for marking and for mortise marking.

Again I am tempted by the cheap square head ones recommended in the David C book from Tilgear (couple of quid each).

But then I saw the round wheel ones and was wondering if this was a better option?

I saw a few posted here that people have made - not sure I have the time as everything takes me ages to make as I am a newbie !

Having said that I do have a nice length of beech fished out of a skip (old door tread).

Was looking at the £6.50 mortise ones fromTilgear (Marples I think).. Any good?

So are the wheel gauges better ?

Is it better to buy a gauge with a blade or a pin ?

What is a good number of gauges to buy ?

What about number of mortise gauges to buy ?

One more thing:

Marking knives...

I made one from a piece of industrial hacksaw blade (about 30mm by 120mm) and this seems to work well. But I was wondering if the japanese ones were better ? Saw one in Tilgear for about £5...

Thanks

Ed