Steve Maskery

Established Member

Having got the design pretty much nailed down, at least for the top, I decided I should make a start. I want to do this quickly, I don't want it dragging on like the wardrobe did. And I want to do it cheaply, too. Twenty-odd years ago, when I built my current bench I was considerably wealthier than I am now and could afford to buy pretty much anything I really wanted. Those days are over, I'm poorer (but a lot happier) now, but it does mean that my pocket money isn't what it was. So I'm using PAR for speed and I'm re-using my present hardware.

The wood I have bought is Vths redwood. That is a grade which is better than BQ (Building Quality) but not as good as Unsorted. It's good on straight and wind but there are quite a few knots. Fortunately the ugliest knots are largely on the faces; the edges, which will make up the top surface, are much better, and by some judicial cutting, I can eradicate several of the knots.

This is the ugliest

So I'm going to make sure that becomes a doghole.

The bottom three of this little lot will be lost when I cut to length

as will these three

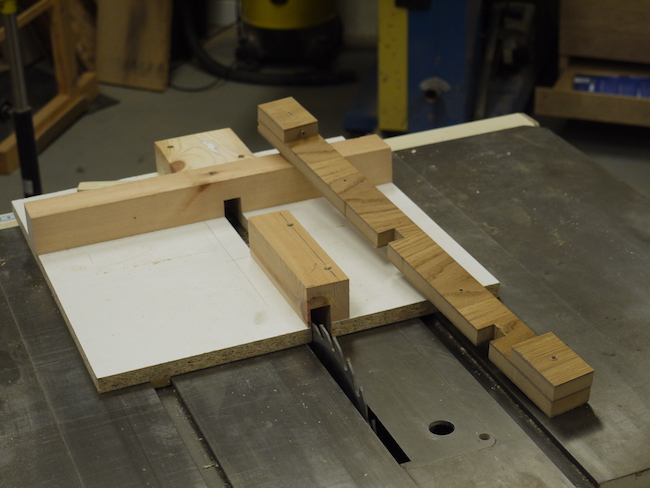

I cut the dogholes with a dado stack

and a jig. If you followed my wardrobe build you will have seen this type of jig before. It is a chipboard base (I realised as I made my first cut that it was not the kindest thing to do to my WC teeth) with a double fence across at 90 degrees. The front half has a hole for an indexing peg. Tunnel guards fore and aft improve the chances of me still being able to count to ten afterwards.

So I line my workpiece up where I want my first doghole to be and make the cut.

Then insert the indexing peg, drop the first doghole over the peg and cut the second and so on.

And before you know it, the whole row is done.

I know a lot of people cannot put a dado stack on their TS, so when I've finished with it, I'll show how to make a similar jig using a standard FTG sawblade.

The wood I have bought is Vths redwood. That is a grade which is better than BQ (Building Quality) but not as good as Unsorted. It's good on straight and wind but there are quite a few knots. Fortunately the ugliest knots are largely on the faces; the edges, which will make up the top surface, are much better, and by some judicial cutting, I can eradicate several of the knots.

This is the ugliest

So I'm going to make sure that becomes a doghole.

The bottom three of this little lot will be lost when I cut to length

as will these three

I cut the dogholes with a dado stack

and a jig. If you followed my wardrobe build you will have seen this type of jig before. It is a chipboard base (I realised as I made my first cut that it was not the kindest thing to do to my WC teeth) with a double fence across at 90 degrees. The front half has a hole for an indexing peg. Tunnel guards fore and aft improve the chances of me still being able to count to ten afterwards.

So I line my workpiece up where I want my first doghole to be and make the cut.

Then insert the indexing peg, drop the first doghole over the peg and cut the second and so on.

And before you know it, the whole row is done.

I know a lot of people cannot put a dado stack on their TS, so when I've finished with it, I'll show how to make a similar jig using a standard FTG sawblade.