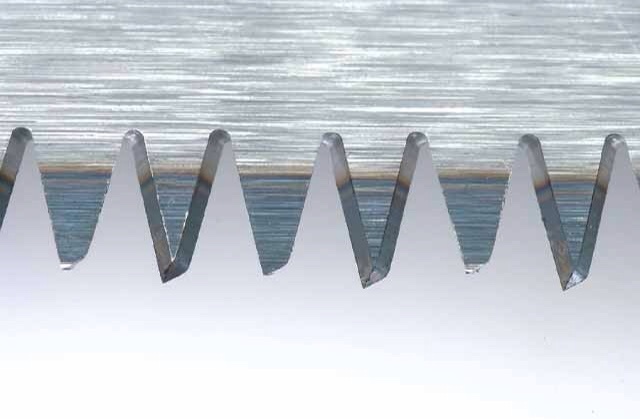

That's a crosscut tooth profile, which is what those saws are intended for. Our western saws with that tooth type always have large teeth, so they will do some coarser work, but it's a crosscut profile.

Japanese teeth that are rip set look a lot like ours. If you have a custom sawmaker make a kataba for cutting hardwoods, then they'll look a lot like ours because they need strength more than a deep gullet (I got my fingers on a $1k custom made saw years ago, it had been made by a guy who makes 25 saws a year and who understood that the buyer wanted it for western hardwoods - it was strong, gave no indication that you could break it even in heavy use - and cut almost like disston teeth. I loved it, but not enough to buy one at that price).

At any rate, use that saw as it is, see how hard the teeth are (they may hold up well enough that sharpening them is years down the road, anyway), and touch them up to their original profile (use magnification if you need to) and don't overthink it.

If you want something for ripping, you should find a vintage rip saw. The difference is night and day, because the fleam is for severing across, and the flat rip tooth severs fibers in the direction of the saw's length.

You'll read a lot on the internet about how saws need to be made of a certain steel, or certain tooth types need to be impulse hardened, but I doubt you'll find that saw lacking. Your ability to use it and keep it in shape is far more important.

Besides, I have broken a tooth off of every impulse hardened saw that I've had at some point or another. The hardness of the teeth may be "forever", but it doesn't help if parts of them break off. I could make your saw last longer than any soft plate hard tooth saw.