HexusOdy

Established Member

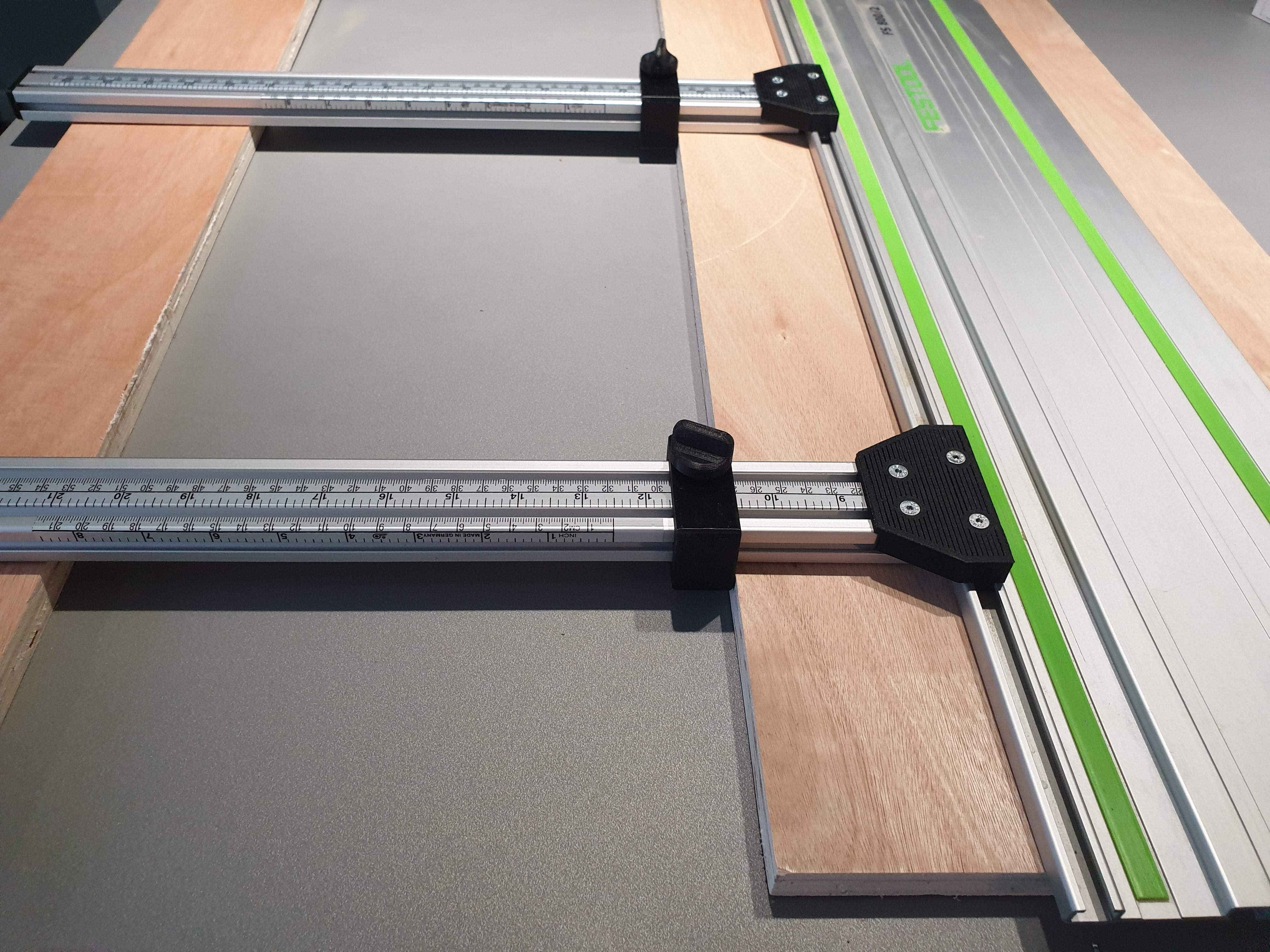

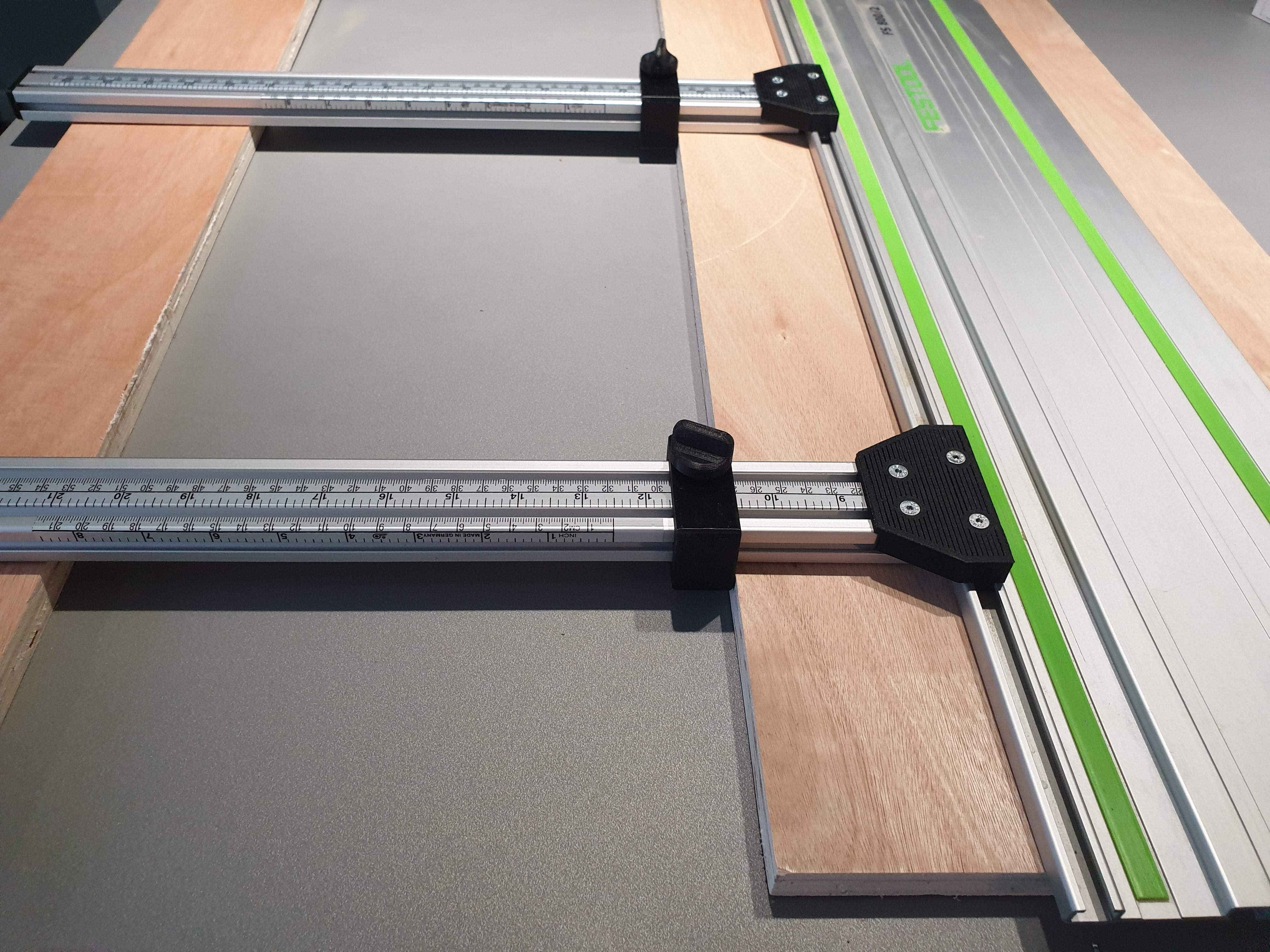

I've had a Makita track saw for a while and it's a handy tool but slow and inaccurate without parallel guides. Something they should all come with out of the box IMO.

It's something I've always wanted to own but just couldn't justify spending £150+ on for what amount to two bits aluminium extrusion with some stops. But then I found a set of guides by Stan Tools (on Ebay or direct at £70 for guides that go up to nearly 70cm depth of cut (67cm is I recall). They do a bigger set too. The minimum cut width is 22cm but they have a thin rip kit for anything less that's an addition £30 and takes that right down to 0.

It's still £70 for two bits of alu extrusion with some stops and rail clamps but it's better than £150+.

They work as all guides do and I'm glad I now have them. It makes using a track saw a lot quicker and if you want a bunch of repeatable cuts it's a must.

I imagine they will also fit other tracks that are Festool and Makita compatible.

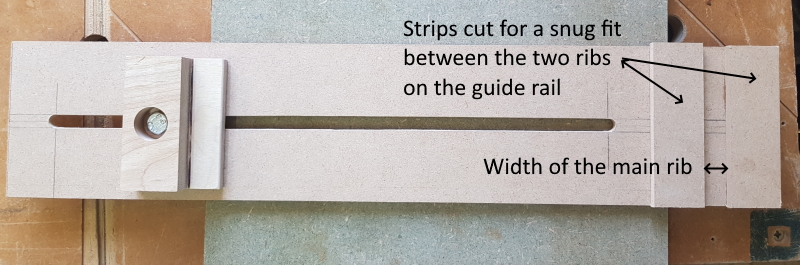

I did get about half a mm twist in the stops when tightened up so that one side of the stop hits the surface and the other has a tiny gap but you can account for that when doing the initial setup and it makes no difference in use.

It's something I've always wanted to own but just couldn't justify spending £150+ on for what amount to two bits aluminium extrusion with some stops. But then I found a set of guides by Stan Tools (on Ebay or direct at £70 for guides that go up to nearly 70cm depth of cut (67cm is I recall). They do a bigger set too. The minimum cut width is 22cm but they have a thin rip kit for anything less that's an addition £30 and takes that right down to 0.

It's still £70 for two bits of alu extrusion with some stops and rail clamps but it's better than £150+.

They work as all guides do and I'm glad I now have them. It makes using a track saw a lot quicker and if you want a bunch of repeatable cuts it's a must.

I imagine they will also fit other tracks that are Festool and Makita compatible.

I did get about half a mm twist in the stops when tightened up so that one side of the stop hits the surface and the other has a tiny gap but you can account for that when doing the initial setup and it makes no difference in use.