JonnyD

Established Member

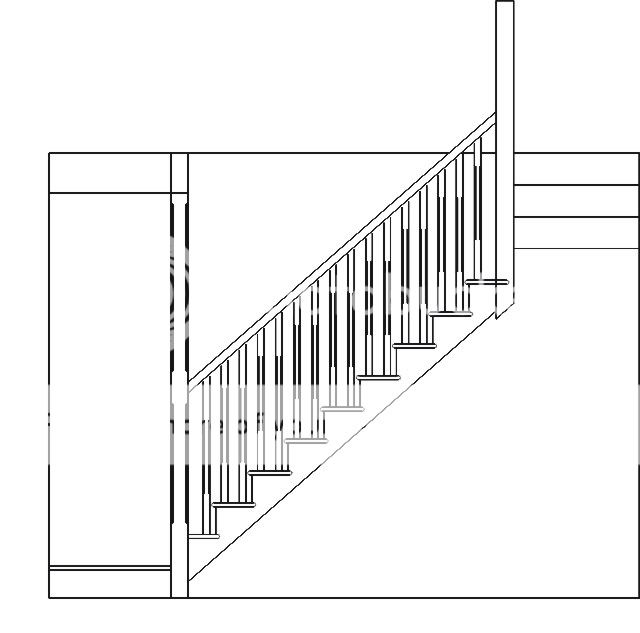

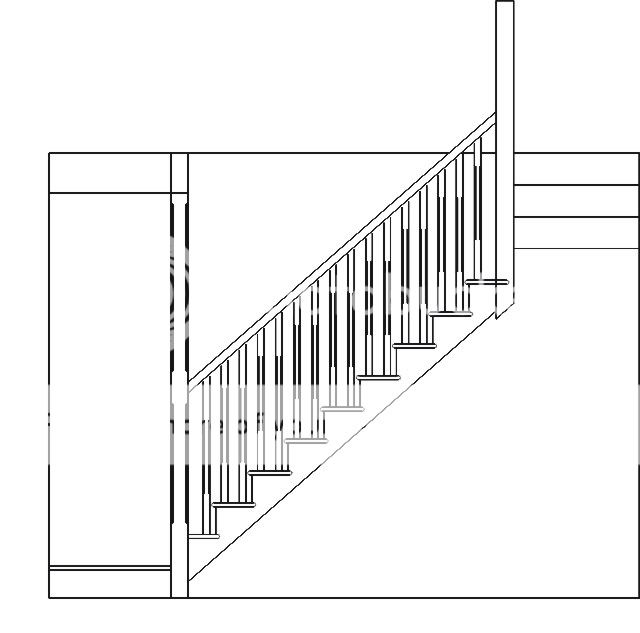

I have just started a staircase and hopefully it will look a bit like this when its finished

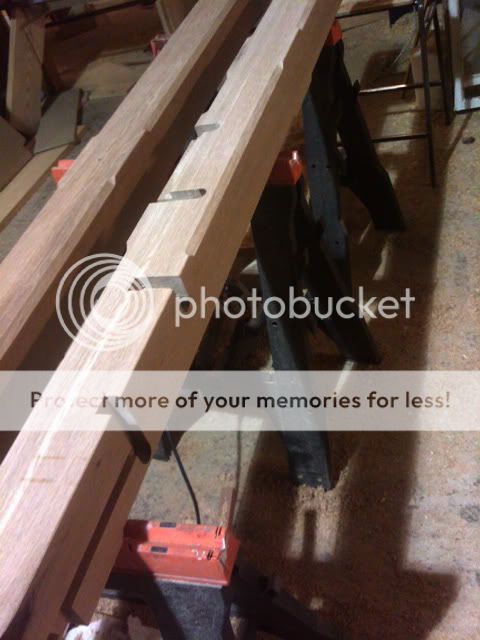

There is going to be a first step quarter landing then a cut string run and then a winder to the top. The architect has cocked up and there is a need for a full height newel to support the floor above to get the required head room. The stairs are going to be painted white and the strings are to be made from southern yellow pine and the treads from 25mm MRMDF and the risers 15mm MRMDF. The Newels and handrail are solid oak and are to be finished with hardwax oil to contrast with the painted staircase.

Strings are cut with a router and jig with a dovetail cutter to give a slight undercut and a tight joint when it is wedged up.

I use a small mdf piece in the jig so that you get a nice neat cut and dont cut to far into the string which is possible with my jig

Riser cut

Tread cut

To do the winder treads the jig needs moving along

Wall side Housed string cut out

The cut string is cut out to the shape of the string using a router and bearing guided cutter. The riser parts are then undercut with a mitre cutter in the router. I use a scribe out of a profile and scribe set.

The back part is then removed so that the riser will fit and join up with the mitre on the string.

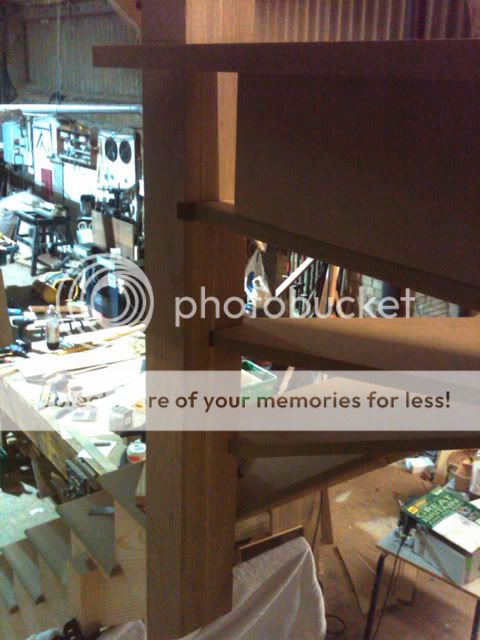

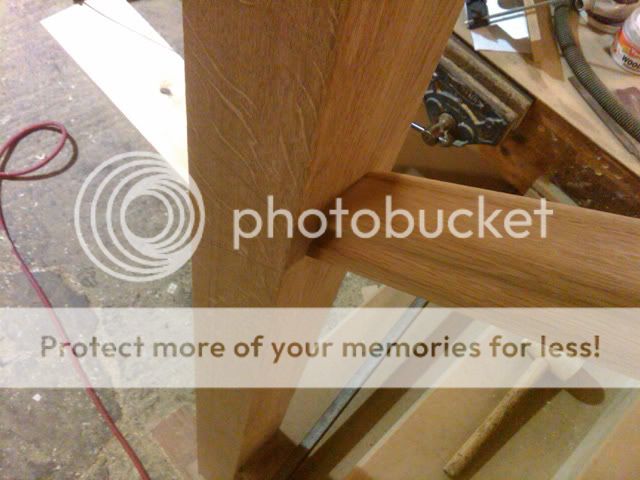

A few stages are missing but the stairs are assembled and then the newels test fitted. The stairs are held up on props and clamps and set perfectly level.

Just got the winders to fit at the top and the handrail and spindles to fit.

will keep you posted

Cheers

Jon

There is going to be a first step quarter landing then a cut string run and then a winder to the top. The architect has cocked up and there is a need for a full height newel to support the floor above to get the required head room. The stairs are going to be painted white and the strings are to be made from southern yellow pine and the treads from 25mm MRMDF and the risers 15mm MRMDF. The Newels and handrail are solid oak and are to be finished with hardwax oil to contrast with the painted staircase.

Strings are cut with a router and jig with a dovetail cutter to give a slight undercut and a tight joint when it is wedged up.

I use a small mdf piece in the jig so that you get a nice neat cut and dont cut to far into the string which is possible with my jig

Riser cut

Tread cut

To do the winder treads the jig needs moving along

Wall side Housed string cut out

The cut string is cut out to the shape of the string using a router and bearing guided cutter. The riser parts are then undercut with a mitre cutter in the router. I use a scribe out of a profile and scribe set.

The back part is then removed so that the riser will fit and join up with the mitre on the string.

A few stages are missing but the stairs are assembled and then the newels test fitted. The stairs are held up on props and clamps and set perfectly level.

Just got the winders to fit at the top and the handrail and spindles to fit.

will keep you posted

Cheers

Jon