jimi43

Established Member

As is normal around here DEREK COHEN of this very parish is your friend...and has some wonderful ideas on that blog.

I made mine out of a piece of thread I found on something in my "junk" pile and drilled out and turned down an old plumb bob as the brass source:

Then I just put a groove in it to tart it up a bit...

I haven't tried knurling yet...but I've kind of got used to this little "bob knob" as I call it!

....and after all...mine was missing so many bits...but it seems to work ok with a QS iron...

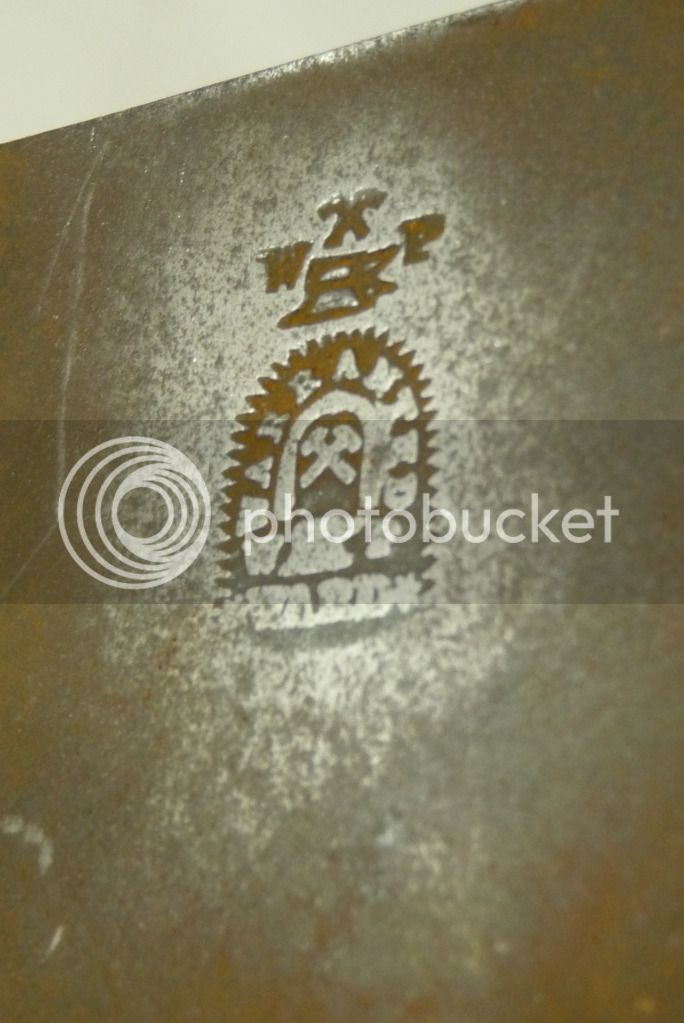

You don't have that problem...with the superb WARD steel...wait till you hone that baby up! :shock:

For your one...I would tend to go a bit further and try to get an original or have one made similar to the original...I'm sure someone on here is more than capable of making one for you close to the original that you would never tell.

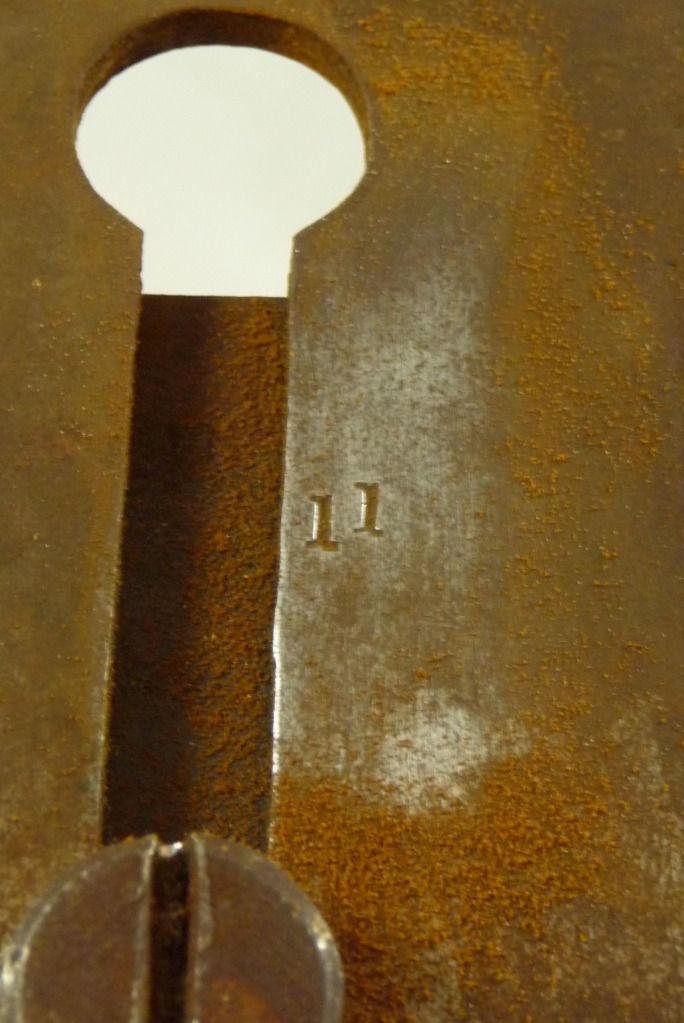

Did you clean up the sides a bit yet? Don't go crazy with the polishing...the natural patina of the plane might be lost. The sole however can be lapped without any problems...you could see if it is dovetailed from the bottom too.

I am still amazed that you got it so cheap but I am made up for you my friend as I know you have been itching for one of these beauties for simply ages. I do hope it lives up to your expectations...I'm sure it will.

Watch out though...this can be a very expensive slope but if you are prepared to wait...bargains are out there. :wink:

Jim

I made mine out of a piece of thread I found on something in my "junk" pile and drilled out and turned down an old plumb bob as the brass source:

Then I just put a groove in it to tart it up a bit...

I haven't tried knurling yet...but I've kind of got used to this little "bob knob" as I call it!

....and after all...mine was missing so many bits...but it seems to work ok with a QS iron...

You don't have that problem...with the superb WARD steel...wait till you hone that baby up! :shock:

For your one...I would tend to go a bit further and try to get an original or have one made similar to the original...I'm sure someone on here is more than capable of making one for you close to the original that you would never tell.

Did you clean up the sides a bit yet? Don't go crazy with the polishing...the natural patina of the plane might be lost. The sole however can be lapped without any problems...you could see if it is dovetailed from the bottom too.

I am still amazed that you got it so cheap but I am made up for you my friend as I know you have been itching for one of these beauties for simply ages. I do hope it lives up to your expectations...I'm sure it will.

Watch out though...this can be a very expensive slope but if you are prepared to wait...bargains are out there. :wink:

Jim