You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Something for the hand tool woodworker who has everything?

- Thread starter Scrit

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Alf

Established Member

Oh I dunno, if it's got some bits it's one for a user; collectors tend to shun rust... Funnily enough I saw a box of bits for such a monster at the car boot a month of so ago, but didn't fully register what they were until later. I gather finding ones that are the right size if you don't have them can be something of a problem.

Cheers, Alf

Cheers, Alf

Only for masochists or people with muscles like Garth! Frankly it's hard enough chopping out all the mortices for an oak gate on a square chisel morticer (give me a chain machine any day) - but the thought of doing it by hand :roll:Alf":3c0qctmb said:Oh I dunno, if it's got some bits it's one for a user........

I somehow doubt that you'd ever find one of these in mint condition - a bit big to leave forgotten on some dusty shelf don't you think.

Scrit

Alf

Established Member

Not too bad, eh?

I think, if you were used to chopping 'em by hand, then one of those monsters would be welcome. But these days, no, I don't suppose anyone but museums and nutters like me would actually want one.

Cheers, Alf

Well it would be if someone hadn't repainted it....... It's really a quantity thing and I doubt that a joiner could survive doing all the morticing by hand (agreed, there may be a very few exceptions), but I can remember seeing quite a few machines like these apparently converted to use an electric motor, yoke and square chisel, presumably in the 1930s or 1940s when the motors became available cheaply enough.

PS Typical museum, that one's missing its' wooden bed

Scrit

PS Typical museum, that one's missing its' wooden bed

Scrit

bugbear

Established Member

Scrit":254vsory said:

Judging by the variety and numbers of these in old catalogues these were in common use up to the 1940's at least.

BugBear

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£234.08

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

CHJ

Established Member

I remember seeing one in use in the 1950's in a village workshop (no electricity) making a new Oak Field Gate for the farm.

The old "bumpers" would probably have been made until WWII (when a lot of things ceased production never to be resumed). Buck & Hickman were still listing the chisels for them in their 1964 catalogue (that's the latest reference I can find for them) but the machines disappeared from their range many years before that. I did try getting hold of some new chisels for one of these in the very lat 1970s, without any joy. Perhaps the lightweight static machines made by Multico, Whitehead, Metalclad and Todd, et al after WWII is what saw them off, although I suspect it was the likes of Wolf - who made relatively low-cost cast drill press/square chisel morticer to work with their electric drills - that did greater damage.bugbear":3bswwuvc said:Judging by the variety and numbers of these in old catalogues these were in common use up to the 1940's at least.

Scrit

Mittlefehldt

Established Member

At the risk of appearing totally ignorant, well actually in this case no risk at all, how do those things work?

By the way I did some two inch deep mortises in North American White Oak (Quercus Alba) by hand and it wasn't that bad.

By the way I did some two inch deep mortises in North American White Oak (Quercus Alba) by hand and it wasn't that bad.

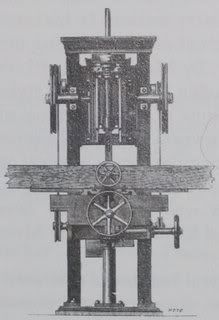

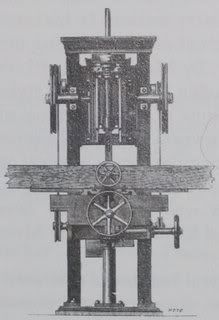

Hi there. They work by holding a chisel much the same way as you wood by hand, but the cut is made by pulling the lever downwards - the fulcrum/lever means that a greater cutting pressure can be achieved much the same as striking the end of the chisel with a mallet. The "carraige" or table can also move left-right and fore-aft to so that once a piece is clamped in a long/wide mortice can be cut quite quickly.Mittlefehldt":3byc7an4 said:.... how do those things work?

By the way I did some two inch deep mortises in North American White Oak (Quercus Alba) by hand and it wasn't that bad.

Doing a few mortices by hand isn't so bad - chopping out a hundred plus a day as they would have in a gate or door maker's workshop might prove slightly more wearing methinks (hammer)

Scrit

bugbear

Established Member

Scrit":1po7zw0z said:Hi there. They work by holding a chisel much the same way as you wood by hand, but the cut is made by pulling the lever downwards - the fulcrum/lever means that a greater cutting pressure can be achieved much the same as striking the end of the chisel with a mallet. The "carraige" or table can also move left-right and fore-aft to so that once a piece is clamped in a long/wide mortice can be cut quite quickly.Mittlefehldt":1po7zw0z said:.... how do those things work?

The machine (obviously?) ensure that the mortise is vertical, and the counter weight on the handle/arm also provides INERTIA when the chisel "hits".

These things were the main method of making production mortices for circa 50-70 years (say 1880 - 1950 - ish)

BugBear

But only in small shops. Square chisel morticers driven on fast and loose pulleys from line shafting appeared between the Great Exhibition of 1851 and the International Exhibition of 1862. The earliest reference I've found to them in the UK is to a machine shown by Samuel Worrsam & Co. of London at the International Exhibition of 1862 although several European companies (nitably Bernier & Arbey of Paris and Zimmerman of Chemnitz) were also manufacturing machine working on a different principle (auger outside of the squaring chisel) by this time. By the 1870s all the major manufacturers with the exception of Sagar (1875) and Wadkin (1897) had been established and almost all of them were offering square chisel morticers, especially as by that time there was more of an accent on joinery machines following the introduction of surface planers and thicknessers using rotating cutterblocks. So it's probable that the hand machines are even earlier in origin.bugbear":3hbh5vng said:These things were the main method of making production mortices for circa 50-70 years (say 1880 - 1950 - ish)

Above: Worrsam & Co square chisel morticer from a catalogue of 1862

Scrit

bugbear

Established Member

Scrit":2911703t said:

Above: Worrsam & Co square chisel morticer from a catalogue of 1862

Scrit

Nice drive by on catalogue ownership, and excellent information. I stand better informed.

BugBear

Similar threads

- Replies

- 12

- Views

- 686