Mr Ed

Established Member

Just at the moment work has been really hectic for me, so difficult to get my teeth into a decent project. I have however, managed to fit in a variety of workshop improvements in the little odd bits of time.

Firstly dust related;

I bought a Camvac 386 twin motor HPLV to deal with my tablesaw and bandsaw;

I did the hopper modification that a few other members have done to their Kity 419 to covert to dust collection from the bottom of the case.

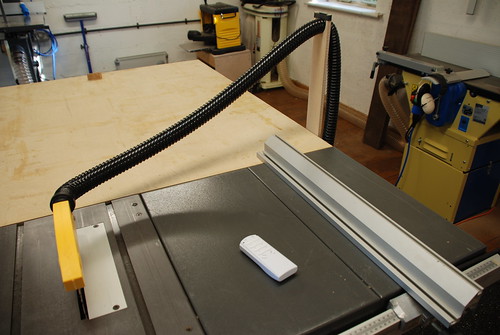

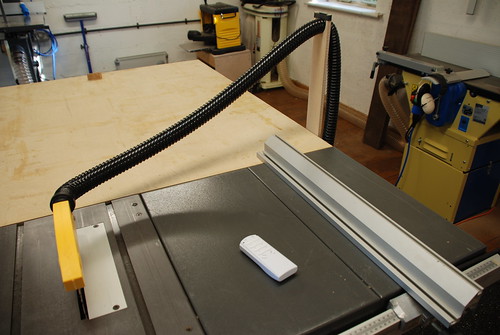

I also added a split off for a smaller hose to connect to the crown guard and added a Maplin remote control plug (remote on the table).

To connect up to the bandsaw I just rotate the Camvac on the wheely stand I made and connect the flexi to the bandsaw ports.

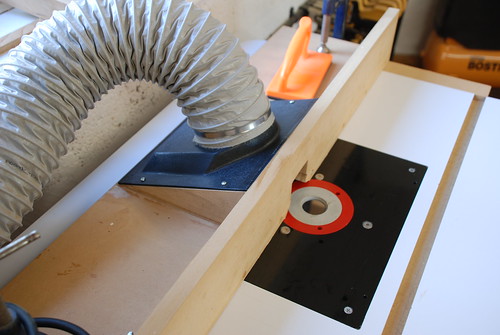

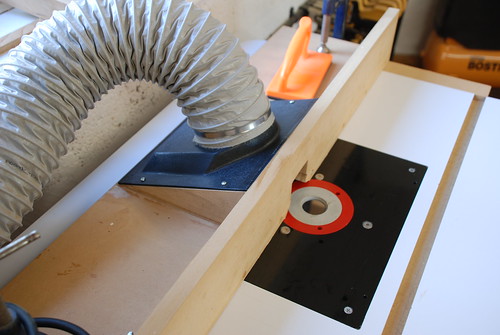

I added a dust extraction port to my existing shop made router table fence, also for use with the Camvac.

The plan is that now the ADE1200 will only serve the planer and thicknesser.

I have had 2 new windows fitted which previously were single glazed and obscure glass, so the shop is now warmer and more light gets in.

Also extended my (basic) clamp storage to cater for some new addditions.

Finally I have added some floor mats. This material is called Regupol - its made of recycled car tyres and is intended for acoustic separation under a screed in high rise resi. Its a bit like the floors you get in kids play areas. Anyway, it was surplus at work and came into my possession - it makes an excellent anti fatigue floor mat.

Thanks for looking

Ed

Firstly dust related;

I bought a Camvac 386 twin motor HPLV to deal with my tablesaw and bandsaw;

I did the hopper modification that a few other members have done to their Kity 419 to covert to dust collection from the bottom of the case.

I also added a split off for a smaller hose to connect to the crown guard and added a Maplin remote control plug (remote on the table).

To connect up to the bandsaw I just rotate the Camvac on the wheely stand I made and connect the flexi to the bandsaw ports.

I added a dust extraction port to my existing shop made router table fence, also for use with the Camvac.

The plan is that now the ADE1200 will only serve the planer and thicknesser.

I have had 2 new windows fitted which previously were single glazed and obscure glass, so the shop is now warmer and more light gets in.

Also extended my (basic) clamp storage to cater for some new addditions.

Finally I have added some floor mats. This material is called Regupol - its made of recycled car tyres and is intended for acoustic separation under a screed in high rise resi. Its a bit like the floors you get in kids play areas. Anyway, it was surplus at work and came into my possession - it makes an excellent anti fatigue floor mat.

Thanks for looking

Ed