Hi superunknown

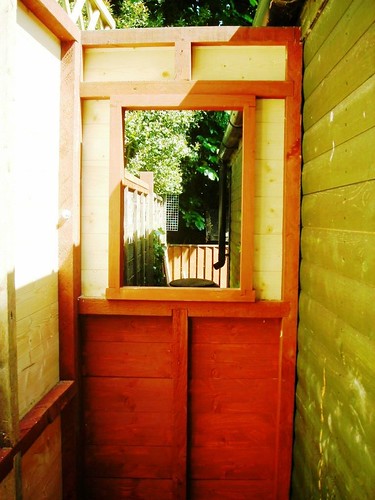

On the outskirts of Lewes. The colour is called Woodland Green. Purchased from Wilkinsons £5.57 as compared with B&Q at £14.31 (9Ltlater

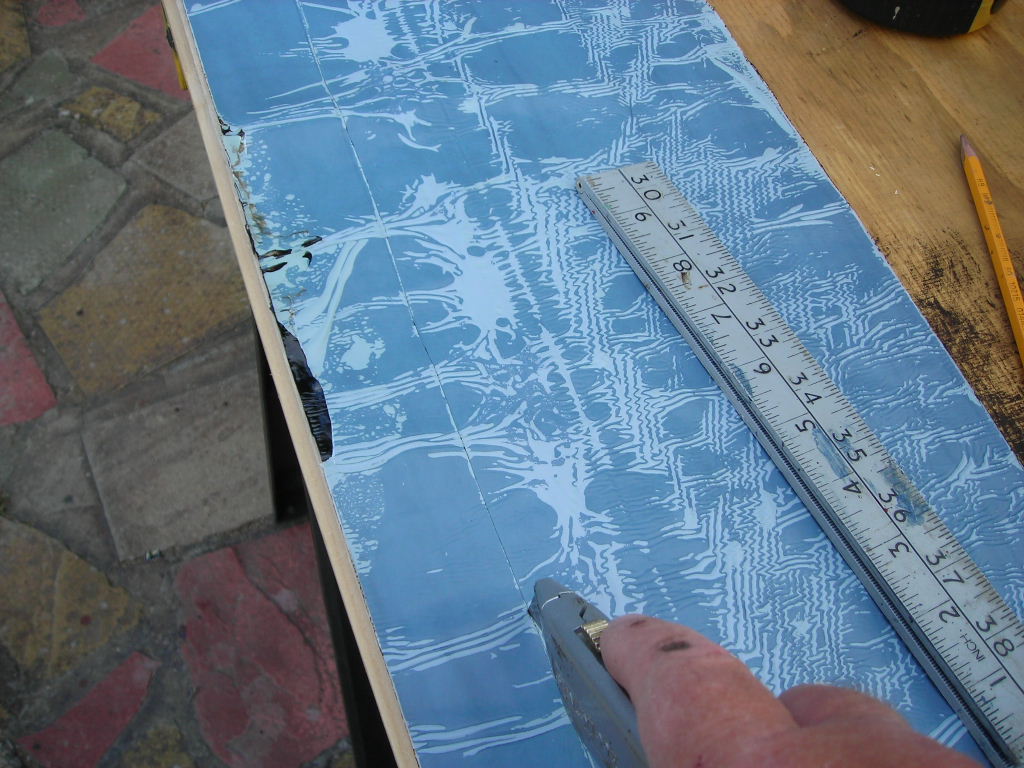

Work has slowed down today mainly titivating around ready to concrete the base. Inserting ragbolts, checking overlaps etc.

It was the intention to concrete the base a week yesterday but with it being a small quantity can be expensive so decided to mix my own. B & Q had some at £164.00 which I thought was reasonable. I went back on Pensioners day for the discount and they had gone. It was an end of line.

Any way purchased the cheapest at £184. I will have other work for it at my pad or my daughters and can always put it on ebay when done. Did check ebay and only two available in my area and they went for over £150.00