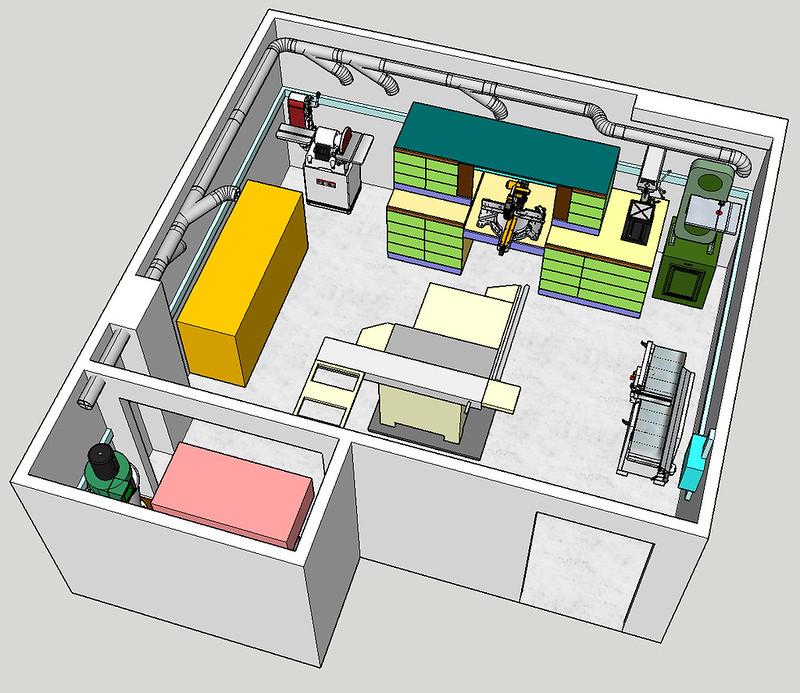

Just thought I would share a sketchup drawing of some drawers/mitre station in my workshop that I did, along with the finished thing. The open front spaces are also on runners allowing me to store the bigger heavier stuff.

The shelf for the mitre saw is removeable and can be lowered to fit the router table stored below it.

The reason for posting the sketchup drawing is to show how useful the program is. I had some pieces of white melamine desktop being thrown out from work which I knew the sizes of. I also knew how long and how high it all needed to be. The wood is all 44mm square or 19mm ply. Sketchup did all the rest of the dimensions and, with an add-in, will produce a cutting list.

All I had to do was to draw it, cut the wood to size, (I didn't check the dimensions at any point), and screw it together, lots of pocket screws. The drawers were all ply boxes with a rebated bottom and a false front, again all measurements read from the sketchup cutting list.

Oh, and I did it all while my right leg was in a full cast!

The shelf for the mitre saw is removeable and can be lowered to fit the router table stored below it.

The reason for posting the sketchup drawing is to show how useful the program is. I had some pieces of white melamine desktop being thrown out from work which I knew the sizes of. I also knew how long and how high it all needed to be. The wood is all 44mm square or 19mm ply. Sketchup did all the rest of the dimensions and, with an add-in, will produce a cutting list.

All I had to do was to draw it, cut the wood to size, (I didn't check the dimensions at any point), and screw it together, lots of pocket screws. The drawers were all ply boxes with a rebated bottom and a false front, again all measurements read from the sketchup cutting list.

Oh, and I did it all while my right leg was in a full cast!