Thanks for the comments folks appreciated, Yes I will be plumbing it in. and by myself.

One of the concessions with SWMBO was one end of the shop to be owned by her. The end wall has a washing machine, tumble dryer and a fridge freezer. (keeps my beers cool) plus a cupboard to keep soaps and the like.

When I built it last month I only had weekends available so each line as a day:-

set out on the rod and down to the timber yard.

mark out and cut to size.

machine the carcass and glue up the end panels

dry fit, adjust and glue up,

make the panel raising jig

Test it out and then search for a new blade for the saw

Make the large door

make the two small doors

Machine the top and glue up

Polyurethane and leave to dry

Hang the doors

Fit in situ.

12 days net but because of supermarket runs, visiting family etc, etc, etc most of July into August. I have had all of August at home.

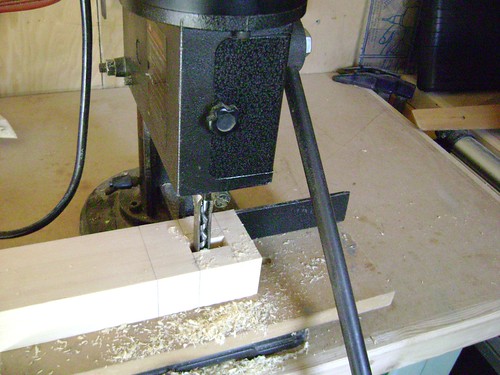

Started a new project in building a wall unit above my pillar drill which I have put on a base that turns it back flush to the wall. This allows me un restricted use when using the O. A saw.

What has taken the time is my struggle putting the pictures on to the site.

I read the instructions off this site but I am a bit slow when reading instructions. I will have another go to gain more experience (belive me I did struggle)

[/img]

[/img]