DannyEssex

Established Member

Is important to have the jaws of your vice square?

Only I'm having a nightmare trying to plane square :lol: I've watched loads of videos on the tube and read so much differing advice I'm forgetting what the advice was :lol:

I have a record 52 1/2 which I picked up at a car boot sale and a lovely Record #5 kindly given to me by Graham Haydon.

For the last week or so I have just been planing some scraps of wood (mostly cheap pine) and trying to get the boards square. I have seen the Paul Sellers video where he uses winding sticks, I would try that but I cant make any as I cant plane square lol,

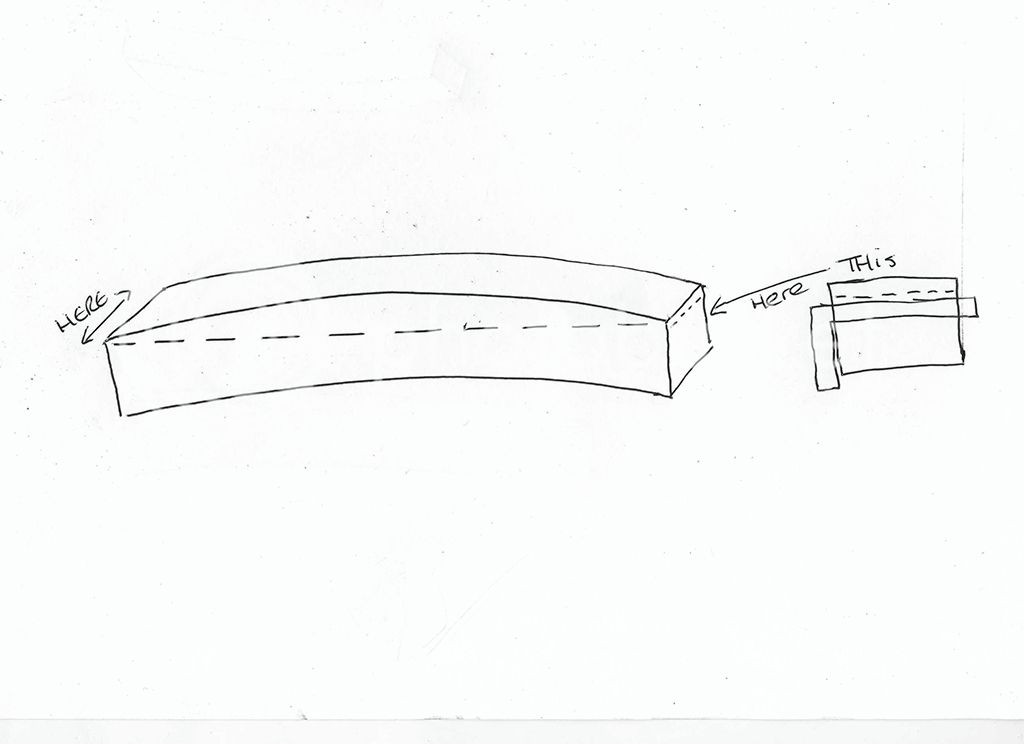

I get a face nice and smooth and with a gnats daylight showing under my square, I then look at the board and its sloped from one end to the other. So I then try and level it out by eye and it starts again, like a vicious circle.

I start off with a 2" thick piece and end up with a 1/2" piece by the time im almost square.

I understand that Its all practice practice, practice, but its frustrating as hell!! My iron is sharp, the sole is flat. I then thought maybe because the faces of the jaws might be off, then maybe that is transferring to my planing????

I'm going to keep at it all week as I have a weeks holiday to kill, so will keep on going, just after a little advice please

Thanks all

Dan

Only I'm having a nightmare trying to plane square :lol: I've watched loads of videos on the tube and read so much differing advice I'm forgetting what the advice was :lol:

I have a record 52 1/2 which I picked up at a car boot sale and a lovely Record #5 kindly given to me by Graham Haydon.

For the last week or so I have just been planing some scraps of wood (mostly cheap pine) and trying to get the boards square. I have seen the Paul Sellers video where he uses winding sticks, I would try that but I cant make any as I cant plane square lol,

I get a face nice and smooth and with a gnats daylight showing under my square, I then look at the board and its sloped from one end to the other. So I then try and level it out by eye and it starts again, like a vicious circle.

I start off with a 2" thick piece and end up with a 1/2" piece by the time im almost square.

I understand that Its all practice practice, practice, but its frustrating as hell!! My iron is sharp, the sole is flat. I then thought maybe because the faces of the jaws might be off, then maybe that is transferring to my planing????

I'm going to keep at it all week as I have a weeks holiday to kill, so will keep on going, just after a little advice please

Thanks all

Dan