.Corneel":1aluq7yd said:Now I am curious of course how the plane works, in comparison with more modern planes. Do you think you could take a good guess about the size and thickness of these stee plates? The weight of a plane is a factor in how it works.

Corneel,

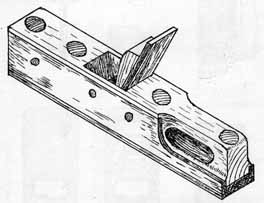

For dimensions, please see my earlier post of 27th July in this thread. I think it is going to weigh at least as much as a Bailey No.5 or even a 5 1/2.

jimi43":1aluq7yd said:WOW! Air Traffic Control of the vise squadron!! That is so cool!

"Permission to land Woden Air 186B Heavy....runway 1A...."

This is a seriously impressive project my friend...and I can't wait for the next episode...

I have a feeling I will have to start mine when you've finished...otherwise things may get a tad confusing....plus I can cheat!

Jimi,

The vice stack-up gets the workpiece to a convenient height for me to work on where I can see it without glasses and not bend my back too much

Yes, it might be a good idea to start yours later

Shrubby":1aluq7yd said:xcellent thread guys

You might find a plane in Christian Peglow's collection of interest

google - hobelaxt tyrol 1800

Thanks, Matt. That is a very interesting site.