devonwoody

Established Member

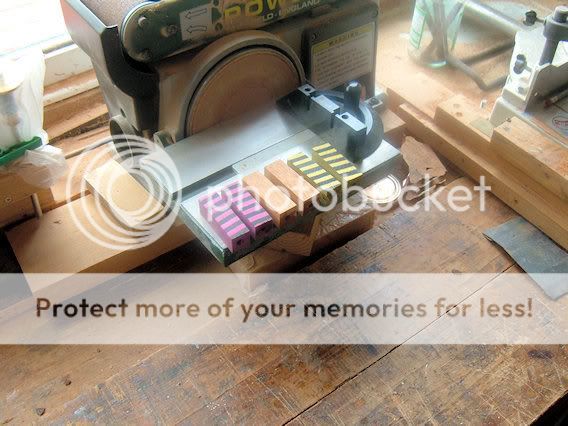

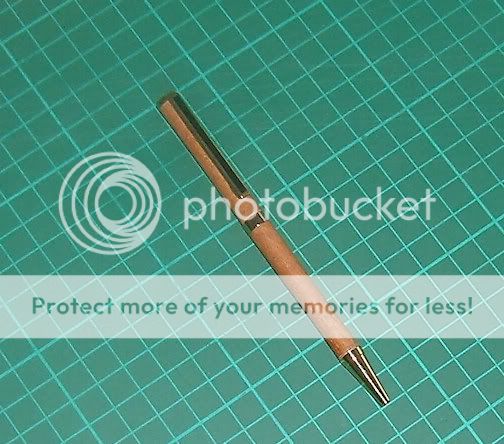

The first pen using the Axminster 310490 kit and timber scrap Meranti from our old exterior window cills.

One hiccup, the barrel trimmer was very aggressive and the top pen section is around 1.5 mm shorter than the nib end. Next time I shall use this tool I think I will get out my old trusty electric portable drill which has a very low starting speed.

One hiccup, the barrel trimmer was very aggressive and the top pen section is around 1.5 mm shorter than the nib end. Next time I shall use this tool I think I will get out my old trusty electric portable drill which has a very low starting speed.