swagman

Established Member

Excellent idea Jacob. Enjoy your nap. =D>

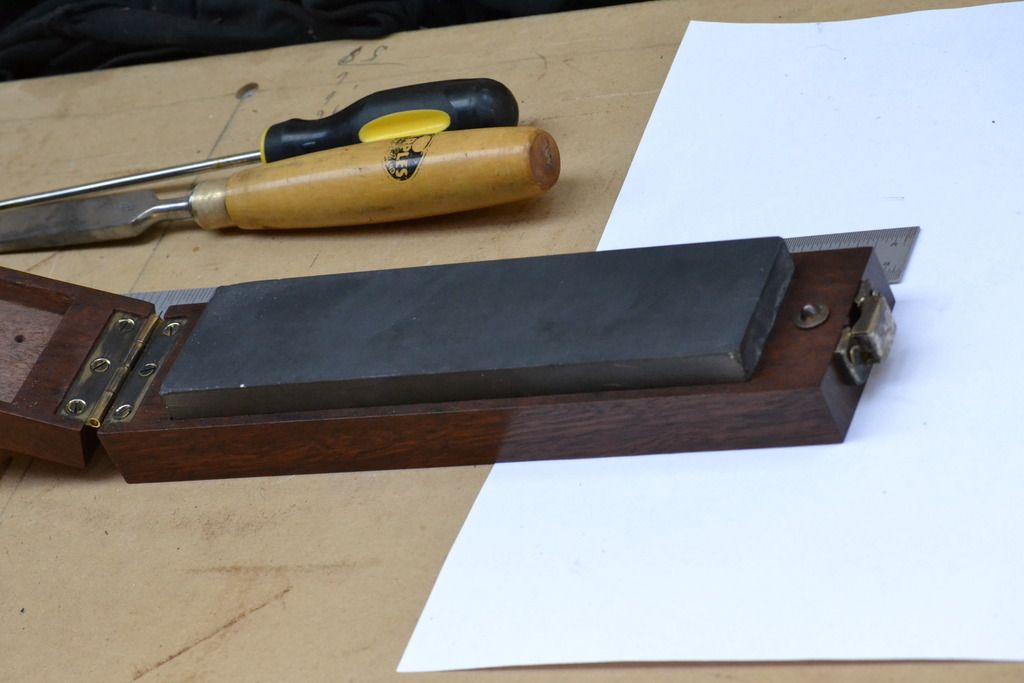

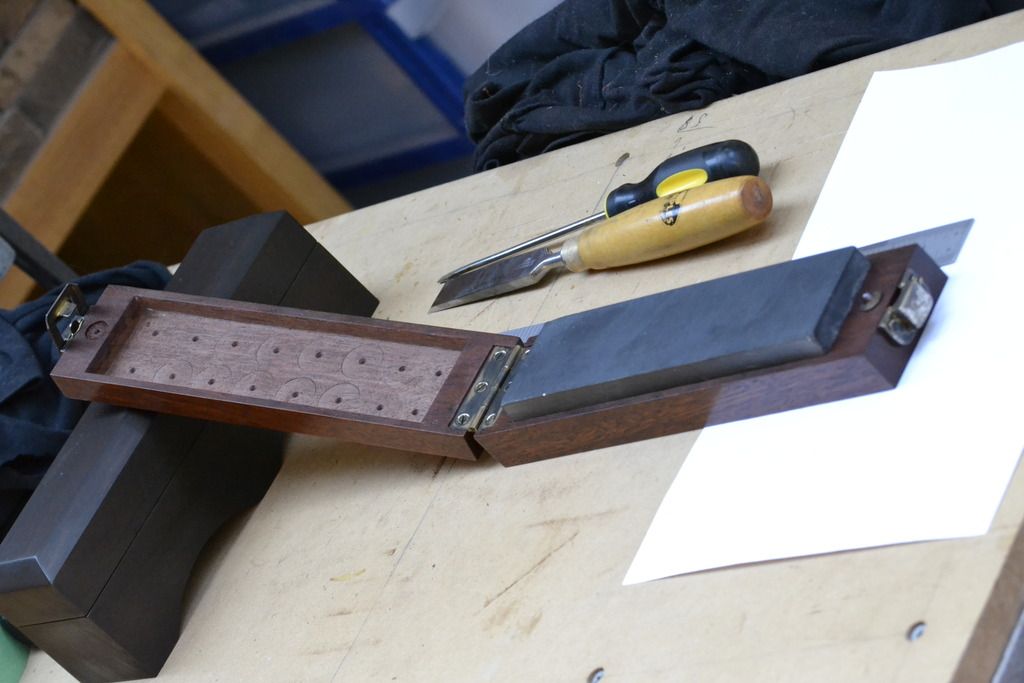

New home for my old Washita:Biliphuster":ymq8avp9 said:I notice that no one has inserted blocks of wood at either end of the stone.

Will do. Early days yet but so far I think they'll hold up fine. As for how well they work, being able to come onto the stone straight from the edge is interesting. Interesting in a good way. I'm less sure of the advantage coming to the end of a stroke but I haven't used it for long or very frequently because I maintain edges with a loaded strop, so my blades need to see stones very infrequently!Biliphuster":37ydnbg8 said:Interesting, could you tell me how they work out?

Basically just two or three should last for life.D_W":22tkk6xf said:....

I think I'm done buying stones for a while, and need to go through my drawers and pull out about a dozen that I have zero chance of using again...

Jacob":szcnwe4l said:Basically just two or three should last for life.D_W":szcnwe4l said:....

I think I'm done buying stones for a while, and need to go through my drawers and pull out about a dozen that I have zero chance of using again...

I've got a few too but not that many!D_W":1u6g47m6 said:Jacob":1u6g47m6 said:Basically just two or three should last for life.D_W":1u6g47m6 said:....

I think I'm done buying stones for a while, and need to go through my drawers and pull out about a dozen that I have zero chance of using again...

Definitely, just as one straight razor should last for life (as long as it's never accidentally brushed into the faucet). I probably have 100 sharpening stones in my machinist bench. I sort of collect them (as todd hughes used to say).

Jacob":3q762i0g said:I've got a few too but not that many!

Over the years you listen to the self proclaimed experts and are persuaded that you really need this that and the other, but as the years go by you don't use a fraction of the stuff, but it is a learning curve I suppose.

adrspach":2tmfr8se said:Collecting stones is just another hobby