CHJ

Established Member

Having got fed up with burning my fingers on a regular basis despite endeavouring to keep abrasive material temperatures at a minimum, and once or twice having to double the amount of finishing work because of a careless score mark made by a rogue (free roaming) abrasive particle, I embarked on the road to power sanding of my turnings.

First Purchase, a hand held Shear Sander tool, was based on nothing more than ‘brand name’ reputation and at first was accepted as a big step forward in ease of use of abrasives and finishing/blending of difficult grain areas.

As there were problems in some areas, near centre of bowl for instance, due to lack of ‘drive’ I next purchased a couple of low cost heads for use in a power drill.

After a couple of weeks of use things started to go negative as far as my experiences with the kit I had.

1. The Shear Sanding Tool that I originally purchased has its shaft running in a bronze bearing; this rapidly heats up when in use. The instructions say to oil this to reduce the friction which is fair enough, what they don’t say is that if you do not cover the rotating shaft and bearing assembly with a piece of cloth immediately after doing his you will spray black oil contaminated waste over your work piece and everything else nearby. When, not if, any bits of loose abrasive get into the shaft/bearing interface there ensues a very rapid modification of the fit tolerances between the two. The adjustment of the head has no locking facility to maintain an angle and I had to resort to fitting a star washer between the components to hold it in desired position.

2. The separately purchased heads were of two patterns, one a plain 50mm straight item (cheap and cheerful) that lasted a couple of uses due to the ‘rubber?’ moulding letting go of the Pronged Tee Nut imbedded in the drive end. This was subsequently ‘fixed’ with a generous layer of Hot Melt glue and still works. The softer more expensive 50mm tapered head rapidly started to show signs of stress at the foam fixing interface with the drive.

3. The relationship between the Velcro hook material on the heads and the cloth backing on the discs was not consistent and lead to several problems in use. The hooks on the Sanding Tool were not as aggressive as those on the separately purchased heads and consequently the abrasive disc peels away without damage, but as the head ‘hooks’ deteriorate due to heat generation, they fail to hold onto some abrasives. The separate heads had much more aggressive hooks fitted and hold onto the abrasives better but will not allow removal of some brands of abrasive without stripping the backing material off the disc.

4. Attempts to repair a failing Velcro hook situation with a self adhesive disc sold for the purpose was a waste of time, the first time an abrasive disc heats up the Velcro adhesive lets go. Velcro hooks were of the ‘good grip’ variety and are stronger than the adhesive bond to the foam baking anyway.

Having asked around as to which ‘heads’ and abrasives other people used and researched the options in the magazines I had, I went to the Stoneleigh show with a view to trying to improve on the situation.

The various alternate heads of the same basic pattern as the ones I have were each promoted by their respective company/stockist as the best of the bunch but did not seem to me to have any better long term prospects for me as a hobbyist where the throwing away of a £7.00 item every couple of weeks does not compute.

The Shear Sanding Tool bearing problems were fixed back to as new within a couple of days by a very customer orientated supplier, but it will be used with considerable circumspect in future due to previous experience.

One system (Grip a Disc) stood out as a possibility during research, marketing itself as overcoming the basic problems of heat generation, and I left visiting this stand till last being a little wary as the system has the disadvantage of single source abrasives and I had read of past problems with abrasive adhesion even with this system. Discussion with the supplier overcame my scepticism and resulted in a purchase of a tool and a selection of sanding discs, a subsequent discussion with Terry (Chestnut) after I noted he was using the tool, resulted in increased confidence and an expansion of my initial purchase.

I have now used the ‘New’ Shear Sanding Tool and its bespoke abrasives on five large diameter bowls in sycamore and ash and can honestly say that my immediate and continuing reaction is that there is no contest between this and my previous systems.

1. Because the head runs in sealed bearings it revolves more readily with lighter pressure and hardly gets warm in use.

2. The head locks positively in angled positions by means of built in locking pin.

3. The abrasives last longer than any of the brands used on the other heads.

4. By the time the abrasive pad baking starts to show signs of deteriorating the abrasive is well past its best.

5. After finishing five bowls through the grades, four out of the first five pads are still in use.

6. The foam backed pads adhere to the conventional Velcro heads and seem to perform better than plain abrasive discs.

Note regarding Velcro backed Abrasives:

Looking at the various brands of ready cut abrasives that I purchased it would appear that although most, but not all, were from respectable Brand sources, they are in the main cut from sheet materiel aimed at fitting to large surface areas such as orbital or large disc sanders, where the contact area is quite large, their performance when used for something only 50mm diameter in such an aggressive application as lathe use would appear to be pushing the material backing a little to far.

Sorry for the long winded dialogue, but I thought the above worth sharing.

First Purchase, a hand held Shear Sander tool, was based on nothing more than ‘brand name’ reputation and at first was accepted as a big step forward in ease of use of abrasives and finishing/blending of difficult grain areas.

As there were problems in some areas, near centre of bowl for instance, due to lack of ‘drive’ I next purchased a couple of low cost heads for use in a power drill.

After a couple of weeks of use things started to go negative as far as my experiences with the kit I had.

1. The Shear Sanding Tool that I originally purchased has its shaft running in a bronze bearing; this rapidly heats up when in use. The instructions say to oil this to reduce the friction which is fair enough, what they don’t say is that if you do not cover the rotating shaft and bearing assembly with a piece of cloth immediately after doing his you will spray black oil contaminated waste over your work piece and everything else nearby. When, not if, any bits of loose abrasive get into the shaft/bearing interface there ensues a very rapid modification of the fit tolerances between the two. The adjustment of the head has no locking facility to maintain an angle and I had to resort to fitting a star washer between the components to hold it in desired position.

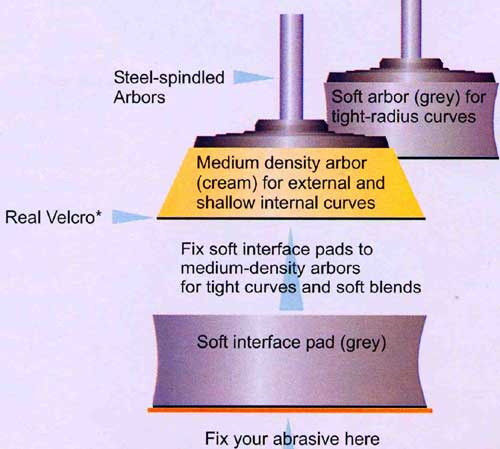

2. The separately purchased heads were of two patterns, one a plain 50mm straight item (cheap and cheerful) that lasted a couple of uses due to the ‘rubber?’ moulding letting go of the Pronged Tee Nut imbedded in the drive end. This was subsequently ‘fixed’ with a generous layer of Hot Melt glue and still works. The softer more expensive 50mm tapered head rapidly started to show signs of stress at the foam fixing interface with the drive.

3. The relationship between the Velcro hook material on the heads and the cloth backing on the discs was not consistent and lead to several problems in use. The hooks on the Sanding Tool were not as aggressive as those on the separately purchased heads and consequently the abrasive disc peels away without damage, but as the head ‘hooks’ deteriorate due to heat generation, they fail to hold onto some abrasives. The separate heads had much more aggressive hooks fitted and hold onto the abrasives better but will not allow removal of some brands of abrasive without stripping the backing material off the disc.

4. Attempts to repair a failing Velcro hook situation with a self adhesive disc sold for the purpose was a waste of time, the first time an abrasive disc heats up the Velcro adhesive lets go. Velcro hooks were of the ‘good grip’ variety and are stronger than the adhesive bond to the foam baking anyway.

Having asked around as to which ‘heads’ and abrasives other people used and researched the options in the magazines I had, I went to the Stoneleigh show with a view to trying to improve on the situation.

The various alternate heads of the same basic pattern as the ones I have were each promoted by their respective company/stockist as the best of the bunch but did not seem to me to have any better long term prospects for me as a hobbyist where the throwing away of a £7.00 item every couple of weeks does not compute.

The Shear Sanding Tool bearing problems were fixed back to as new within a couple of days by a very customer orientated supplier, but it will be used with considerable circumspect in future due to previous experience.

One system (Grip a Disc) stood out as a possibility during research, marketing itself as overcoming the basic problems of heat generation, and I left visiting this stand till last being a little wary as the system has the disadvantage of single source abrasives and I had read of past problems with abrasive adhesion even with this system. Discussion with the supplier overcame my scepticism and resulted in a purchase of a tool and a selection of sanding discs, a subsequent discussion with Terry (Chestnut) after I noted he was using the tool, resulted in increased confidence and an expansion of my initial purchase.

I have now used the ‘New’ Shear Sanding Tool and its bespoke abrasives on five large diameter bowls in sycamore and ash and can honestly say that my immediate and continuing reaction is that there is no contest between this and my previous systems.

1. Because the head runs in sealed bearings it revolves more readily with lighter pressure and hardly gets warm in use.

2. The head locks positively in angled positions by means of built in locking pin.

3. The abrasives last longer than any of the brands used on the other heads.

4. By the time the abrasive pad baking starts to show signs of deteriorating the abrasive is well past its best.

5. After finishing five bowls through the grades, four out of the first five pads are still in use.

6. The foam backed pads adhere to the conventional Velcro heads and seem to perform better than plain abrasive discs.

Note regarding Velcro backed Abrasives:

Looking at the various brands of ready cut abrasives that I purchased it would appear that although most, but not all, were from respectable Brand sources, they are in the main cut from sheet materiel aimed at fitting to large surface areas such as orbital or large disc sanders, where the contact area is quite large, their performance when used for something only 50mm diameter in such an aggressive application as lathe use would appear to be pushing the material backing a little to far.

Sorry for the long winded dialogue, but I thought the above worth sharing.