TobyB

Established Member

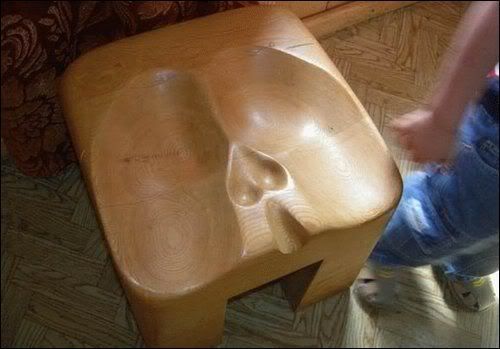

I bought an elm seatblank to make a traditional-ish sort of carved seat (not got a bandsaw ... yet ...ordered one!) which I've started to work on.

Planed the top and bottom smooth to see the grain and decide which side will be which - no problems.

I've planned to a Veritas pullshave to carved the seat out - read the thread here suggesting an Arbotech to clear the worst - worried about lack of control - not sure how easy the pullshave will be to use either.

The sides though - tried a jack and a block plane for the slight convex curves of the front and back and they look OK. But the tighter curves of corners and the concave curves of the sides ... tried a spokeshave and got poor results with a lot of chatter in places ... tried push and pull strokes both perpendicular and oblique ...

The spokeshave is a cheap'n'cheerful Stanley 151 I've had lying around little used until now - scarey-sharpened as best I can.

I'm wondering if the problem is a bad workman using the completely wrong tool , a bad workman not using the right tool properly, or a bad workman using a poor tool?

Planed the top and bottom smooth to see the grain and decide which side will be which - no problems.

I've planned to a Veritas pullshave to carved the seat out - read the thread here suggesting an Arbotech to clear the worst - worried about lack of control - not sure how easy the pullshave will be to use either.

The sides though - tried a jack and a block plane for the slight convex curves of the front and back and they look OK. But the tighter curves of corners and the concave curves of the sides ... tried a spokeshave and got poor results with a lot of chatter in places ... tried push and pull strokes both perpendicular and oblique ...

The spokeshave is a cheap'n'cheerful Stanley 151 I've had lying around little used until now - scarey-sharpened as best I can.

I'm wondering if the problem is a bad workman using the completely wrong tool , a bad workman not using the right tool properly, or a bad workman using a poor tool?