I fitted this system to my Elektra Beckum swapping blades takes 2 mins and they are really good blades.

http://www.advancedmachinery.co.uk/mach ... s-1455-382

Jim

http://www.advancedmachinery.co.uk/mach ... s-1455-382

Jim

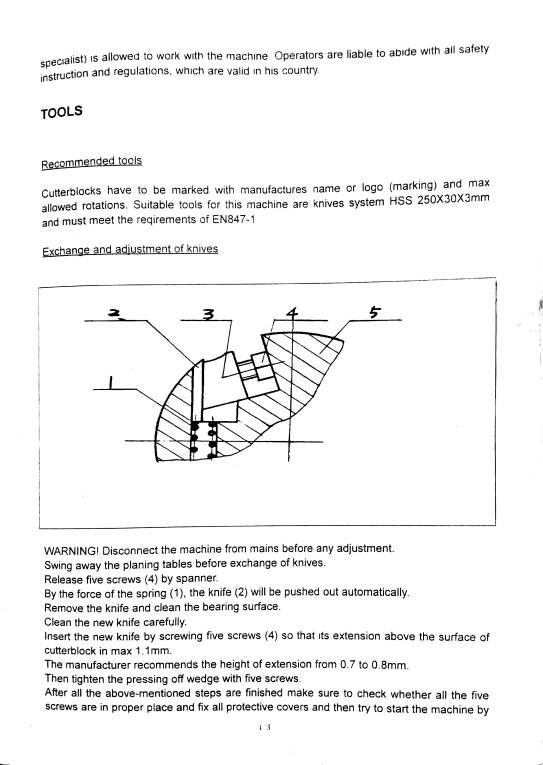

Would something like this be an option http://www.axminster.co.uk/planer-blade ... jig-700360 I'll go against the grain and say I found it easier using this, than the stick method. The joy of it is it holds the blade at exactly the same repeatable height, until you pinch the bolts up tight.r0nmlt":3itwgfdu said:I will scan the manual page tonight and post.

I would use the stick setup if the outfeed table is setup correctly. This is the reason I am trying to reference the blades to the cutter head and then be able to set the outfeed table correctly with the stick method, then finally the infeed to be co-planar to the outfeed. In my head it makes sense, don't know if it is the proper way.

The Axminster AW106PT2 had this tool but unfortunately mine didn't. My version is a nameless machine. I scoured even the insides of the machine, motor assembly, everywhere. If there ever was a name on it, there isn't now. The manual too doesn't have any reference to manufacturer or name.

Take the springs out ? If the magnets hold them in place....r0nmlt":ofuvrzoi said:The problem with these jigs, although they look very precise, is the strong springs that push up the blades. It requires a bit of effort to push down the blades really low into the cutter head. I cut an arc of MDF with a 75mm diameter to sit on the blades and push them down as I tighten the screws. It works but not sure if the blades are actually parallel to the cutter head or not. There is no consensus on how high the knives should be from the cutter head. Nonetheless i found out that anything in excess of 1.5mm will make the blades hit the outfeed table.

MDF too soft for the jig. Mines aluminium. Soft enough not to blunt the blade at the two contact points. And it's effectively two jigs 8" apart so the blades are bound to be parallel to the block.r0nmlt":26dqc0yt said:The problem with these jigs, although they look very precise, is the strong springs that push up the blades. It requires a bit of effort to push down the blades really low into the cutter head. I cut an arc of MDF with a 75mm diameter to sit on the blades and push them down as I tighten the screws. It works but not sure if the blades are actually parallel to the cutter head or not. There is no consensus on how high the knives should be from the cutter head. Nonetheless i found out that anything in excess of 1.5mm will make the blades hit the outfeed table.