Sawdust=manglitter

Established Member

With this TV cabinet/sideboard i’ve been making (link below) I’m planning on using oak burr panels for the cabinet doors.

tv-cabinet-sideboard-t110601.html

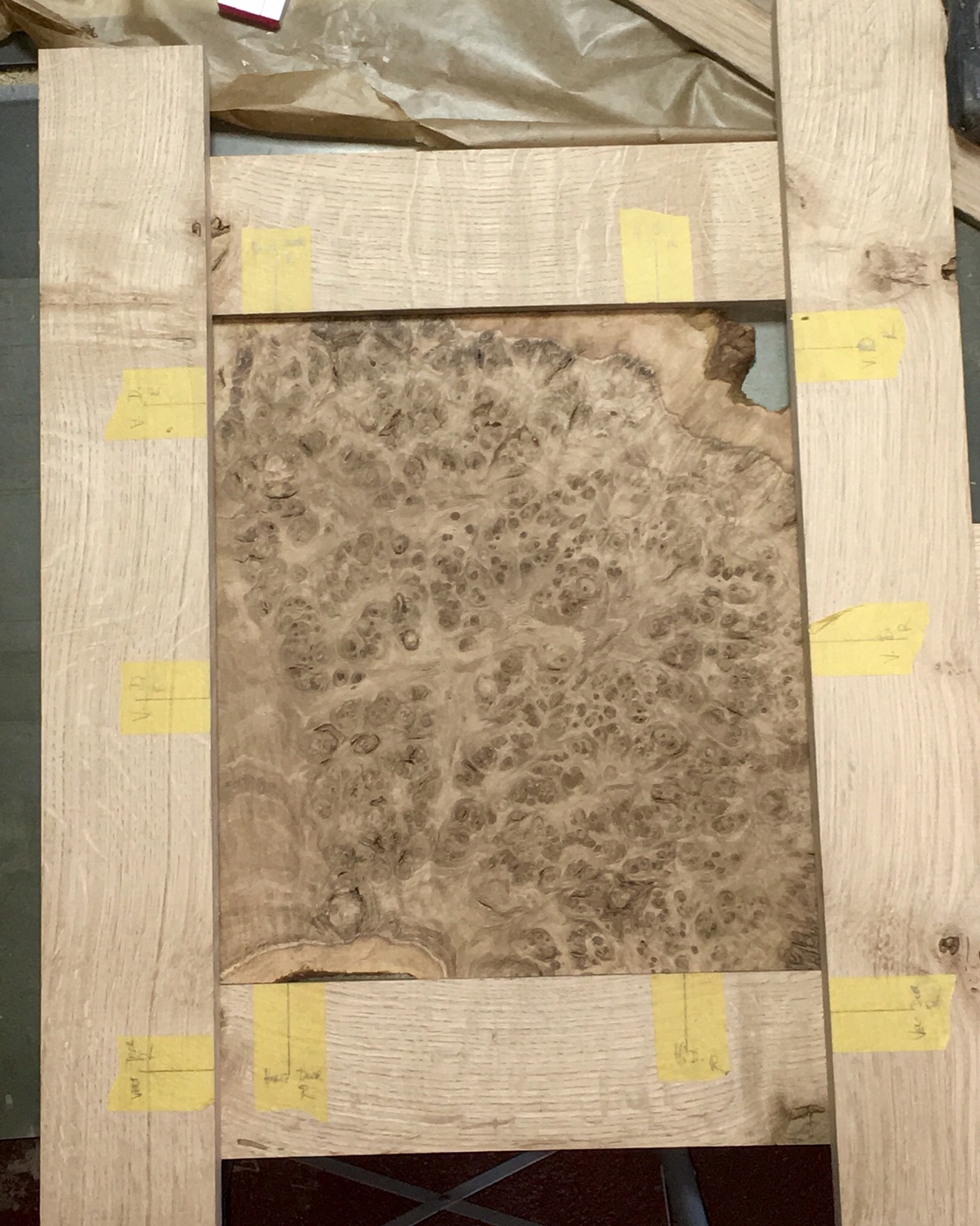

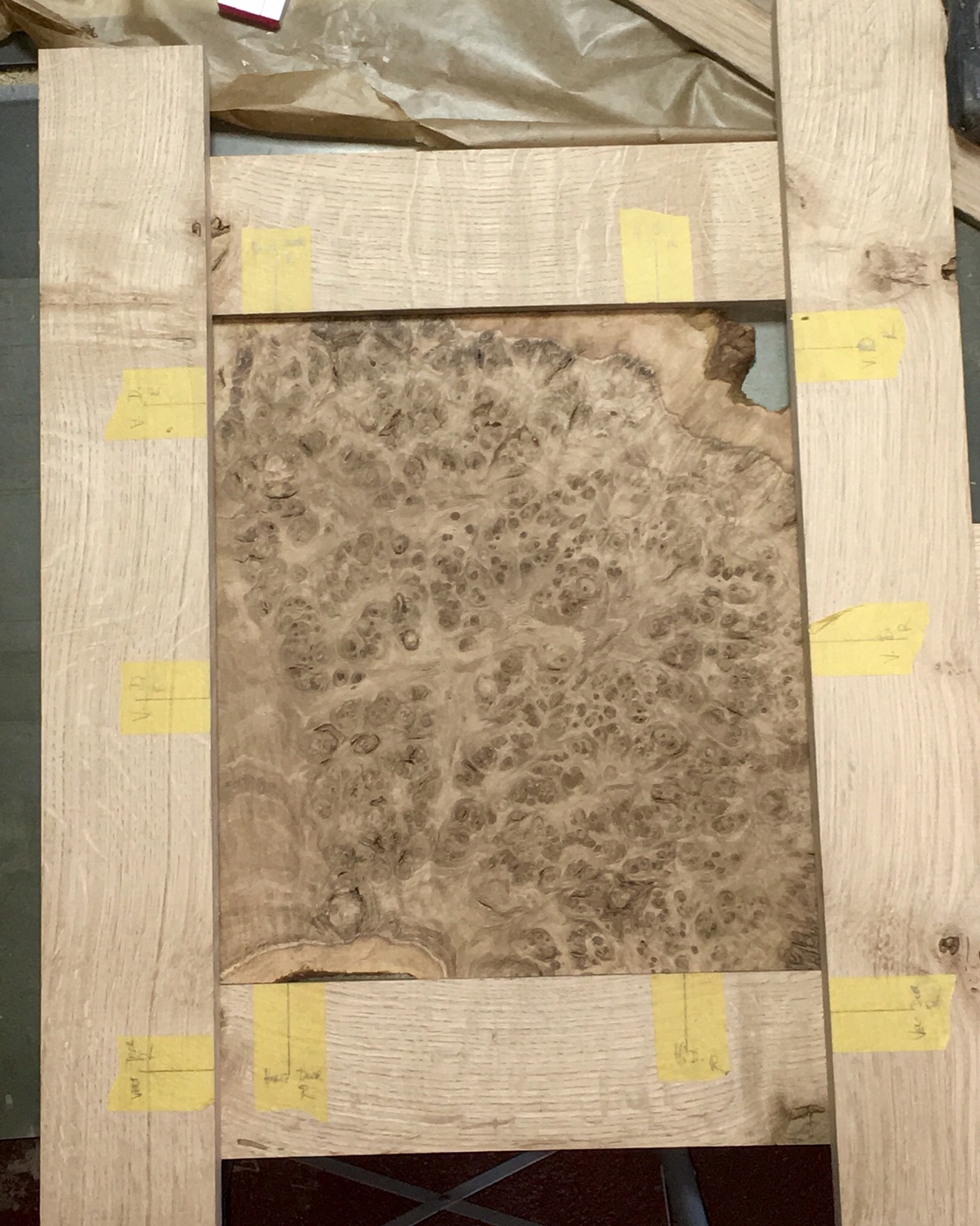

I wont be ready to do the doors for a few weeks, but i’m just thinking ahead. I had a pretty big oak burr which i cut the slices from, so these panels are 10mm thick. The photo below shows one of the panels alongside the stock i have earmarked for the frame of the door.

My question is, how much should i expect oak burr to move seasonally? Would it be less than a standard straight grained plank of wood as the grain is denser and in all directions?

Thinking ahead i am... the burr wasnt quite as wide as i would’ve liked as i was limited by the capacity of my bandsaw so the burr is around 303mm wide, which compared to the wood i have earmarked for the frame of the doors would mean i currently only have around 5mm each side of the panel to fit into grooves which doesnt seem much to me. So can i get away with that, or do i need wider stock for the door frames to account for more movement?

tv-cabinet-sideboard-t110601.html

I wont be ready to do the doors for a few weeks, but i’m just thinking ahead. I had a pretty big oak burr which i cut the slices from, so these panels are 10mm thick. The photo below shows one of the panels alongside the stock i have earmarked for the frame of the door.

My question is, how much should i expect oak burr to move seasonally? Would it be less than a standard straight grained plank of wood as the grain is denser and in all directions?

Thinking ahead i am... the burr wasnt quite as wide as i would’ve liked as i was limited by the capacity of my bandsaw so the burr is around 303mm wide, which compared to the wood i have earmarked for the frame of the doors would mean i currently only have around 5mm each side of the panel to fit into grooves which doesnt seem much to me. So can i get away with that, or do i need wider stock for the door frames to account for more movement?