Mike, I've seen this at least 3 dozen times. When I first wrote an article about using a cap iron, this was the instant reply over and over.

I have no idea why you'd think I wouldn't have seen it before. do you think that such a common thought would be only unearthed by you? It's probably even on this forum.

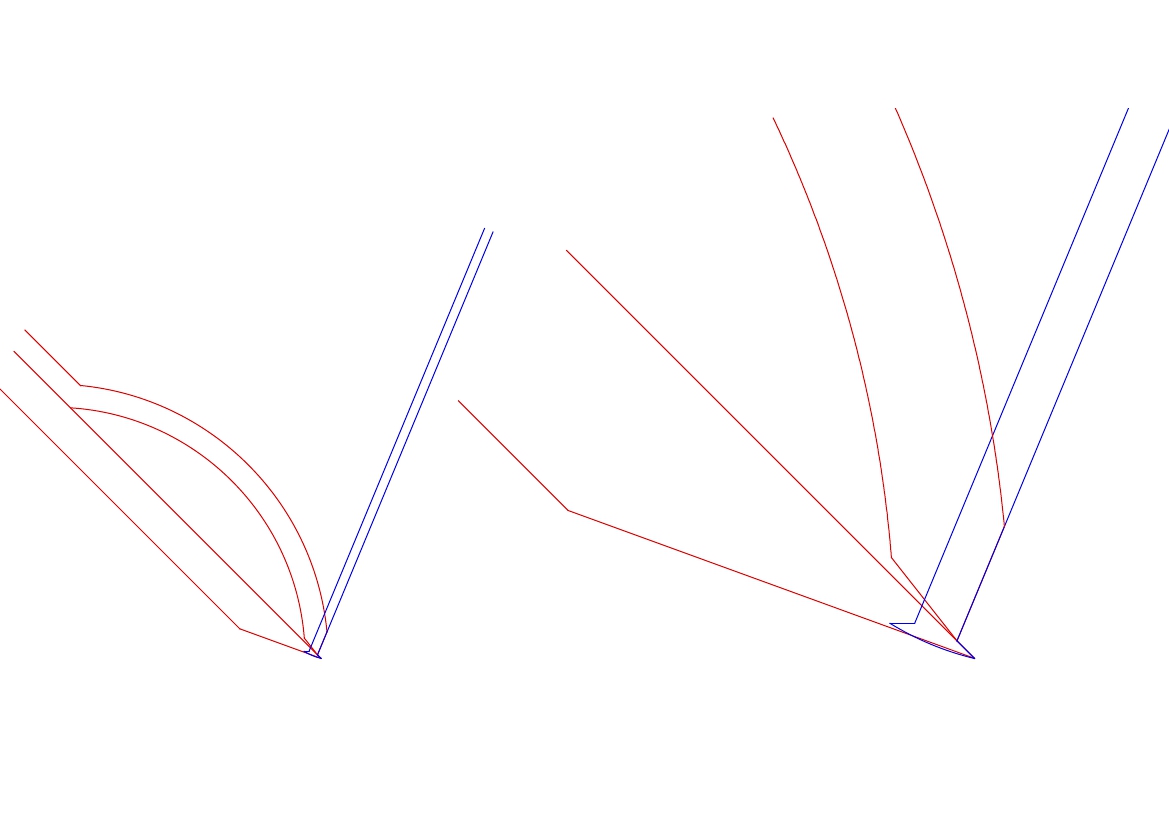

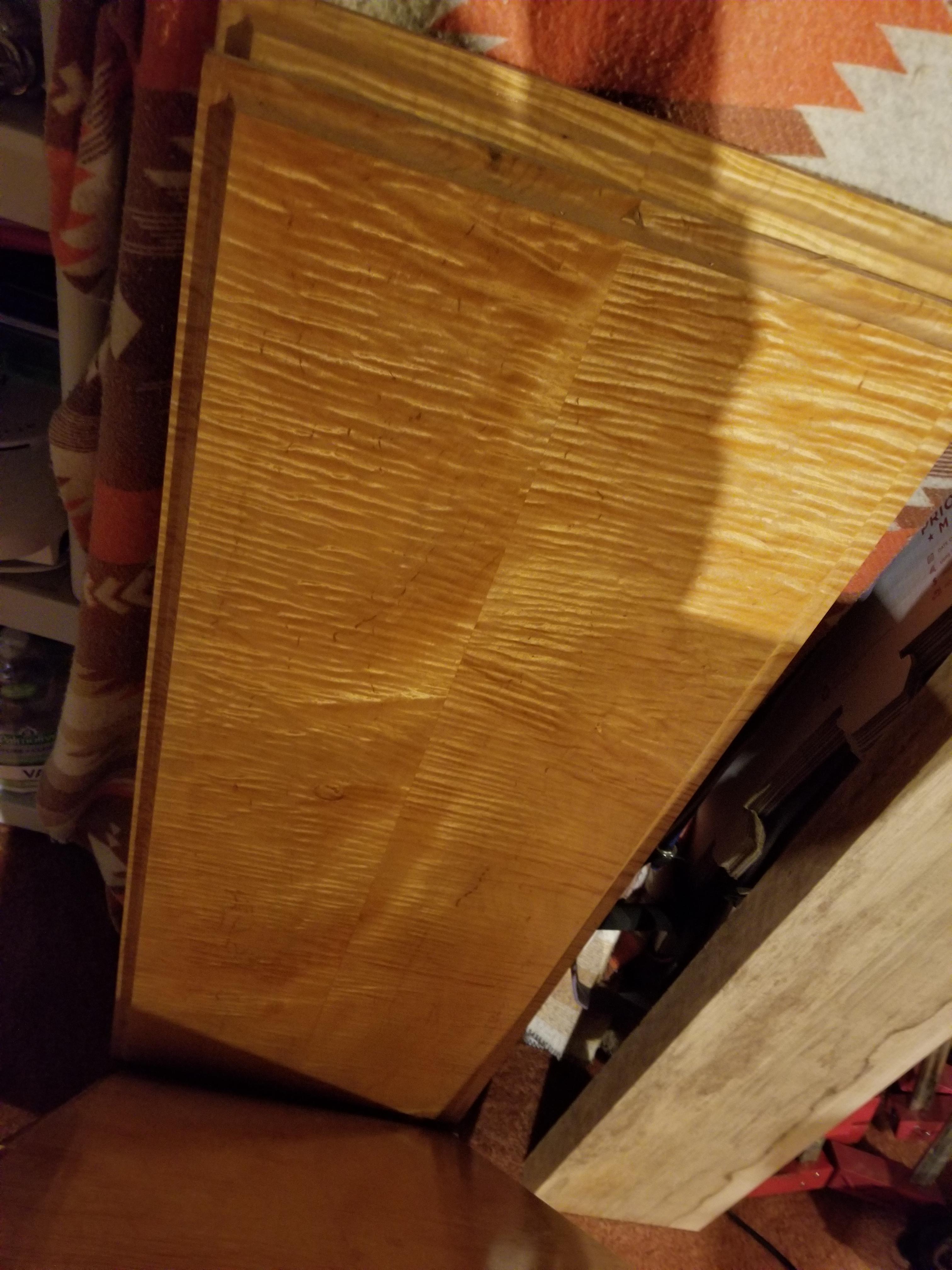

As far as whether or not I'd have thought of it myself, it's literally an essential consideration in matching the burr size on a scraper to the amount of work that you're going to do. Think about it. It'll garner some oohs and aahs from beginners, but you are thinking things I considered a decade ago, but instead of just supposing these things, I went on to actually test them. It was the ineffectiveness of high angle planes and smoothers that drove me to the double iron. AT the time I started to figure the one professional woodworker here in the states (who works by hand) was probably right because I had just scraped all of these panels with everything I could think of - a large scraper plane, a card scraper (then planed with a high angle plane at 60 degrees, which is absolute torture) and finally after they had cupped and the large scraper plane was not able to do any volume of work, I listened to the advice of someone on another forum who noted that the smaller scraper plane would follow a less than perfect surface better. It did, but that expensive little plane wasn't necessary, and neither was something foolish, filthy and slower like belt sanding the cupping out.

boards like these are easily planed to finish - probably in about a tenth of the effort. A friend and I had no power tools that would work them cleanly, so we glued them together and had them thicknessed by someone with a giant multi drum sander (a 52" beach thicknessing sander). Ideally, you like to join things and get them together so that they cannot move on you, but in this case, using other peoples' equipment hamstrung us. If you're not following, I had to get the cup out of the finished panels to some extent to be able to get a finished surface on them as a beach sander leaves deep long rasped lines in the surface of wood. That means more than smoothing, or perhaps an hour or two of such a thing (at risk) to knock the cup out of these panels. It was horrendous. Single iron planing is risky (at common pitch), or punishing (at higher pitch) for anything other than small material removal. .

Inability to use the double iron on something like this (Without buying something else like a shop drum sander) exposes incompetence in anyone who doesn't know how to use a double iron.

I would dimension these from rough without issue at this point. You have no idea how far behind you are, but it's almost comical that you'd think I haven't seen or heard of this "a scraper is doing the same thing as a double iron plane" bit before. The funny thing is, the first person I can recall saying it was wilbur pan, who I had a slight distaste for at the time because he has a horrible habit of thinking about things, posting the results of his thoughts and not actually trying them.

you could probably learn something here that would serve you well. I figured this out in isolation because there was no literature that was really that reliable on describing it and a few hundred board feet of dimensioning is the only place that you're really going to learn it well. Is it possible for someone who likes scraping and machine planers to get something from it pretty quickly? I think so, but it is easier for me to know it well because I"m not using anyone else's borrowed knowledge. You are.