bugbear

Established Member

A neighbour was recently kind enough to give me his late father's saw vice.

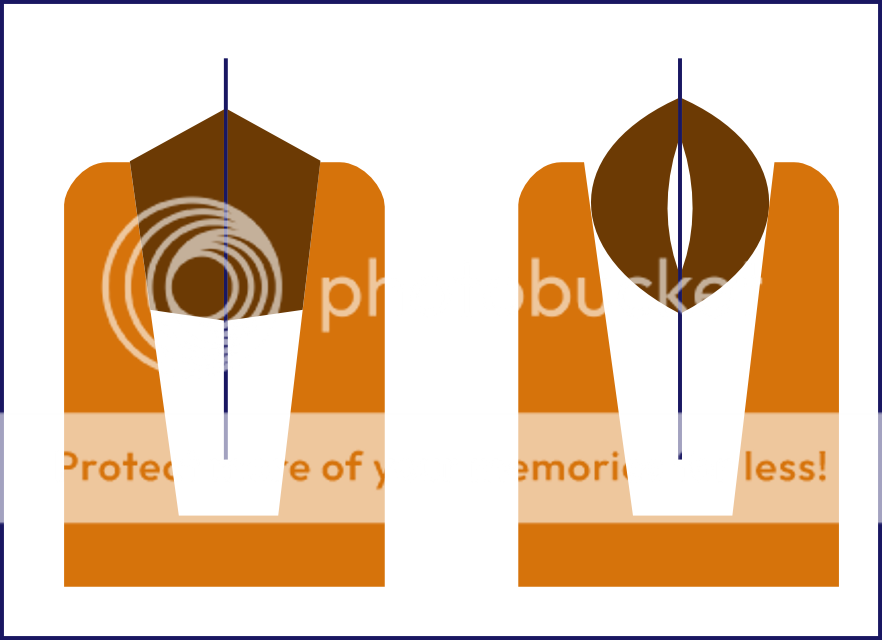

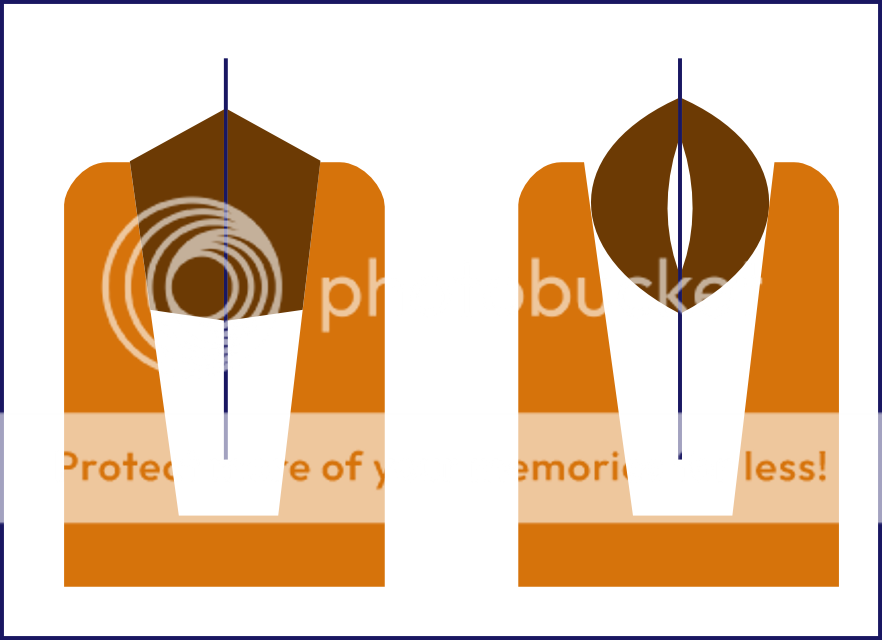

This was a traditional "saw chops" where a pair of hardwood strips are pushed into a 'V' shaped jaw in the main frame. The frame is similar to this one:

http://www.cornishworkshop.co.uk/wwsawvice.html

A wrinkle in this design, which the donated vice showed me, is that the cross piece should be of a height to sit in your bench vice.

However, in the donated design, the jaw pieces had a tapered half lap, that fitted exactly in the 'V' of the stand's jaws. In this design, all the tapers must match exactly for the saw to be held nicely.

Further, the faces of the jaw pieces must be truly flat to hold the saw.

The lazy slob (or is that design genius) in me didn't like the notion of the all this precision being required, so this thought occurred to me:

The trad design is on the left. My "deskilled" version is on the right.

The curves are completely non critical, which is rather the point.

This design (almost) cannot help holding the saw tightly, right near the teeth.

Comments and suggestions are welcome.

BugBear

This was a traditional "saw chops" where a pair of hardwood strips are pushed into a 'V' shaped jaw in the main frame. The frame is similar to this one:

http://www.cornishworkshop.co.uk/wwsawvice.html

A wrinkle in this design, which the donated vice showed me, is that the cross piece should be of a height to sit in your bench vice.

However, in the donated design, the jaw pieces had a tapered half lap, that fitted exactly in the 'V' of the stand's jaws. In this design, all the tapers must match exactly for the saw to be held nicely.

Further, the faces of the jaw pieces must be truly flat to hold the saw.

The lazy slob (or is that design genius) in me didn't like the notion of the all this precision being required, so this thought occurred to me:

The trad design is on the left. My "deskilled" version is on the right.

The curves are completely non critical, which is rather the point.

This design (almost) cannot help holding the saw tightly, right near the teeth.

Comments and suggestions are welcome.

BugBear