There seem to be a lot of things one can do, ranging from putting your router under a table, to top of the range incra jigs on amazing tables.

i started here:

http://www.woodpeck.com/wpproducts.html because i wanted simply a fence and mitre that were parallel and micro adjustable. however after i built the options i wanted, it was well over £1,000!

the other option of a table with your own router, seemed to have problems with how to accurately raise / lower the router. I like to do a cut slightly off what i know i want, and then raising very very slowly, home in on the actual cut, testing the fit each time, until its right, then route all my parts in one go.

the raising and lowering seems to be a problem, most routers are a bit jerky and one worries a lot that after moving any micro adjusters and plunging it back, that i have moved it more than the 1/1000 i intended...

i ended up getting a woodstar table (I think B52), that has a built in router, with a handle out the side, that you can rotate to get as fine as you like adjustments.

only cost £150

was either that or expensive lifter, in expensive table etc...

downsides are that there is no way to ensure the fence is parallel to the mitre, no micro adjusters to move fence back / forward, and the build quality is not that great.

if there are any others out that that you find that do this, let me know and i will upgrade, however this device does me fairly well now that i understand it's limitations, and anything involving a bearing guide, like mouldings is perfect.

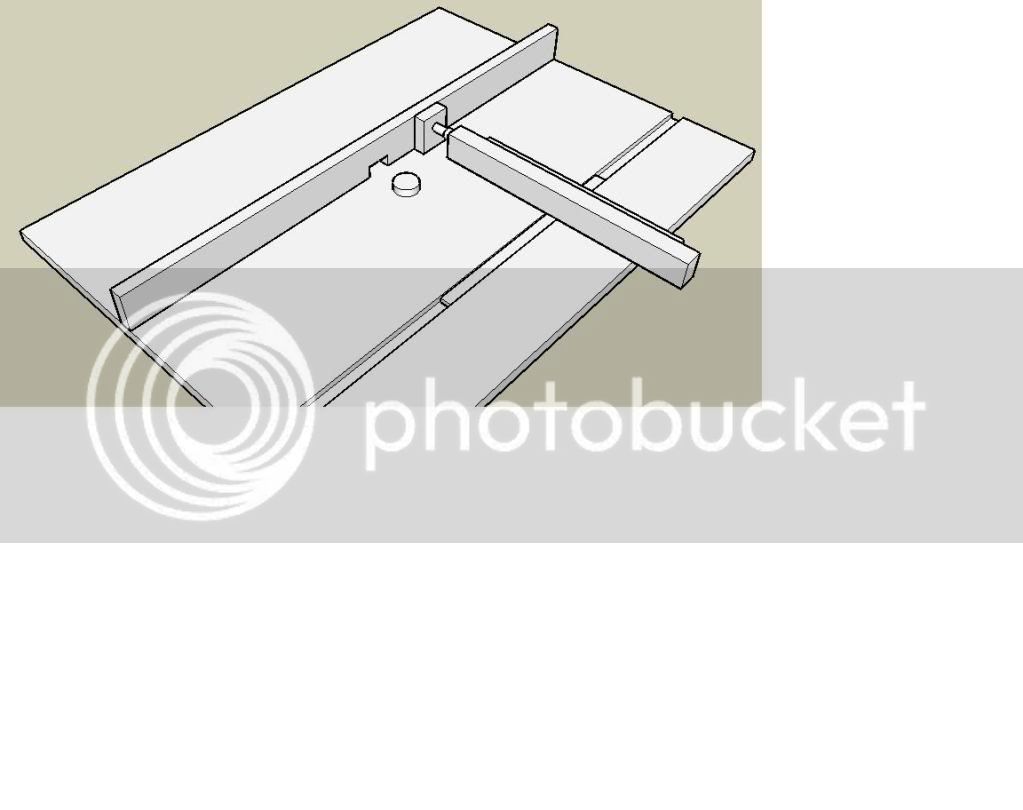

ideally all i would be looking for is a table where i can turn a wheel to move a fence back / forward parallel to mitre gauge in tiny increments, and also move the router up / down in tiny increments.

however i feel for this i need to start building something closer to £1,000 then £150