OPJ

Established Member

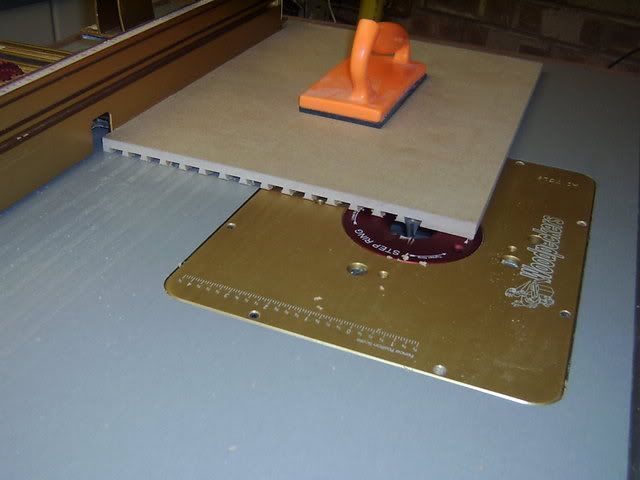

I've had the Bosch RT 60 router table for a good couple of years now, although, to be honest with you, it's had relatively little use. It looks identical to Trend's original Craftsman router table, for those of you that know it, while it's not too distant a design from the newer MkII version either.

I bought a 1,900w 1/2" Freud router almost a year ago for this and I'm very happy with the setup, although I find the mounting plate to be 'crowned' slightly in the centre which means I cannot get it truly level with the rest of the table. Apparently, this is a common thing which should allow for the weigh of the router in order to prevent deflection - but what can I do about it? Do you think that making a new plate for something like 4mm acrylic would be better?

I'd also like to ask you about dust extraction when freehand routing against a bearing-guided cutter. Does anyone have a succesfull solution to all that mess going everywhere? Below, you can see the plastic guard designed for this table - I was thinking about drilling a 32mm hole directly above the cutter for my extractor, unless someone has a better idea?

(Don't worry, of course there should be a Guide Pin in place - but this is only for photographic purposes! :wink: )

)

Extraction in the above setup didn't really cross my mind until I read the article in British Woodworking on Table Routers where extraction below the table was advised. Personally though, I find those plastic extraction ports get in the way and affect your maximum plunge depth.

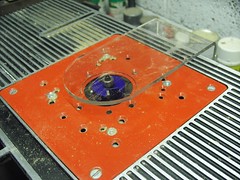

....Unfortunately, as you can see in the photo above, I went to the trouble of fitting the extraction port this past weekend and, upon tightening the second screw (which didn't seem to want to go in) I heard a 'CRACK' and incredibley managed to split the router's base ever so slightly!! :shock:

Hopefully Freud will be able to help me with this though - I had a previous problem with the motor when I first bought the router and they were absoluetly superb in getting it checked, tested, repaired and returning to me in a flash of light!

Thanks, in advance, for your help guys - sorry I've gone on a bit, I seem to do that quite a lot! :roll: :wink:

I bought a 1,900w 1/2" Freud router almost a year ago for this and I'm very happy with the setup, although I find the mounting plate to be 'crowned' slightly in the centre which means I cannot get it truly level with the rest of the table. Apparently, this is a common thing which should allow for the weigh of the router in order to prevent deflection - but what can I do about it? Do you think that making a new plate for something like 4mm acrylic would be better?

I'd also like to ask you about dust extraction when freehand routing against a bearing-guided cutter. Does anyone have a succesfull solution to all that mess going everywhere? Below, you can see the plastic guard designed for this table - I was thinking about drilling a 32mm hole directly above the cutter for my extractor, unless someone has a better idea?

(Don't worry, of course there should be a Guide Pin in place - but this is only for photographic purposes! :wink:

Extraction in the above setup didn't really cross my mind until I read the article in British Woodworking on Table Routers where extraction below the table was advised. Personally though, I find those plastic extraction ports get in the way and affect your maximum plunge depth.

....Unfortunately, as you can see in the photo above, I went to the trouble of fitting the extraction port this past weekend and, upon tightening the second screw (which didn't seem to want to go in) I heard a 'CRACK' and incredibley managed to split the router's base ever so slightly!! :shock:

Hopefully Freud will be able to help me with this though - I had a previous problem with the motor when I first bought the router and they were absoluetly superb in getting it checked, tested, repaired and returning to me in a flash of light!

Thanks, in advance, for your help guys - sorry I've gone on a bit, I seem to do that quite a lot! :roll: :wink: