Good day

I had to rip a few small pieces for some router table aid/fixture and I would like to share with you the method.

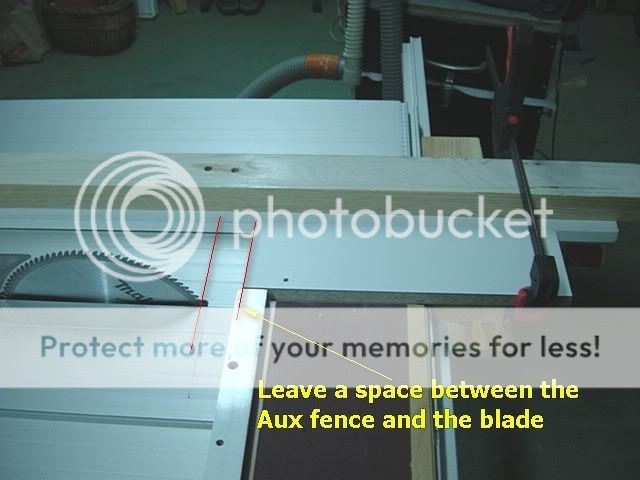

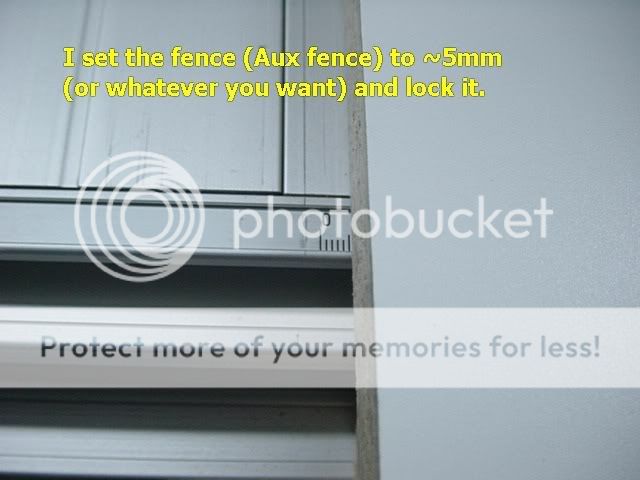

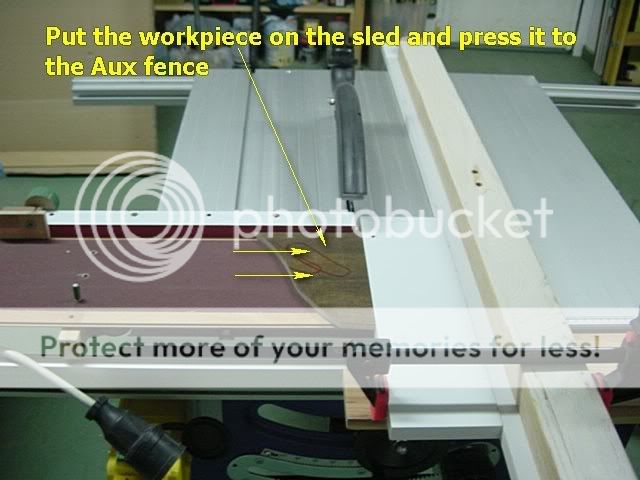

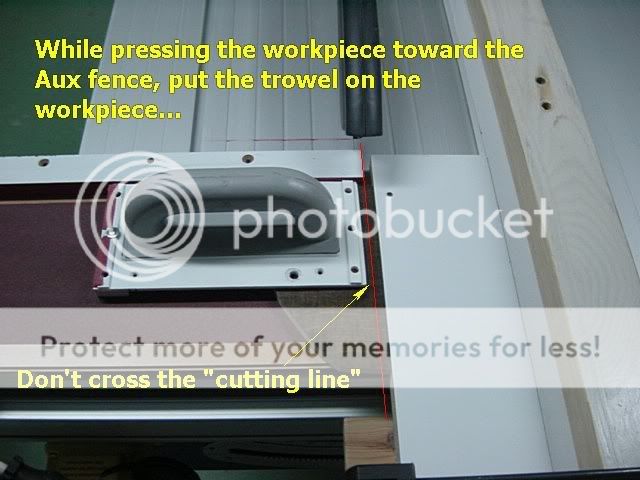

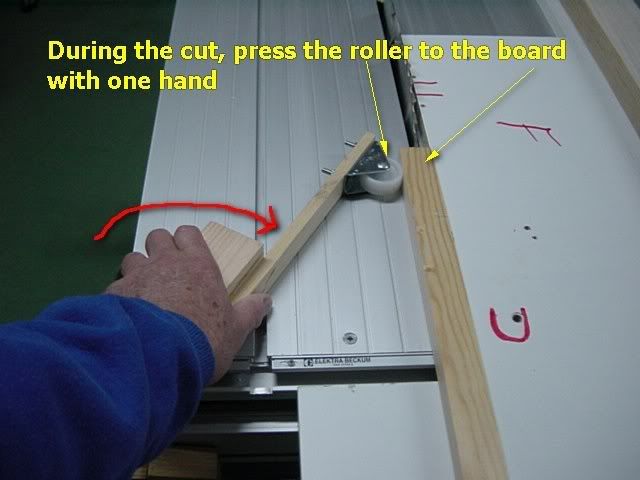

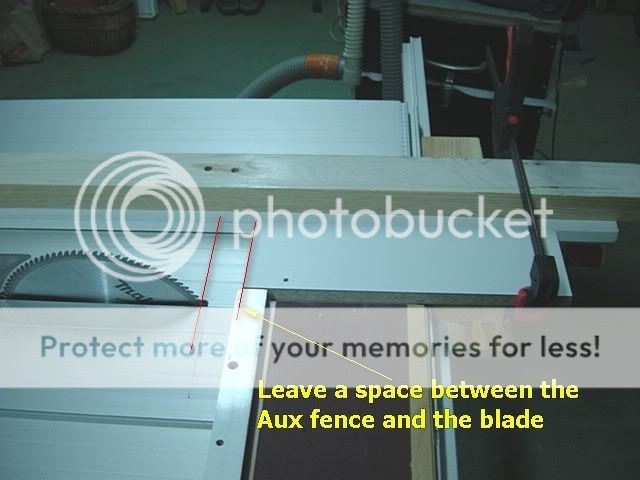

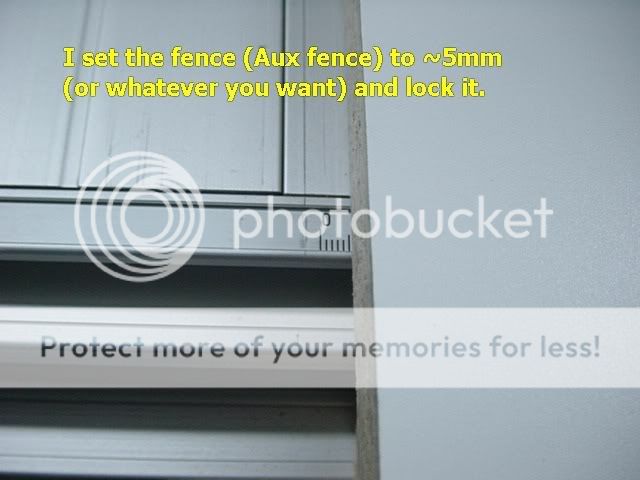

I'm using an Auxiliary fence clamped to the rip fence...now, when I'm saying Aux fence.... give me some good width say, 100~150 mm....you don't like to "drive" in congested areas, do you...

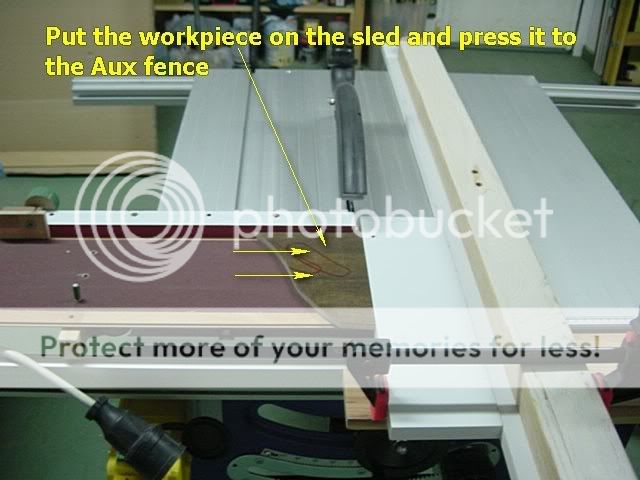

Before clamping the aux fence, give it a pass through the blade just to make sure that its parallel and consistent in width.

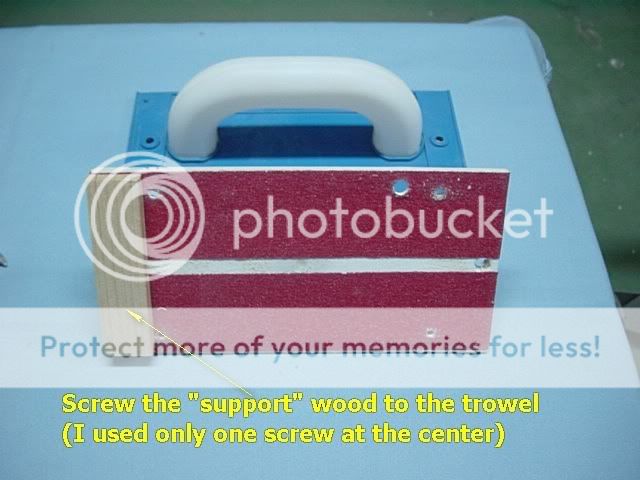

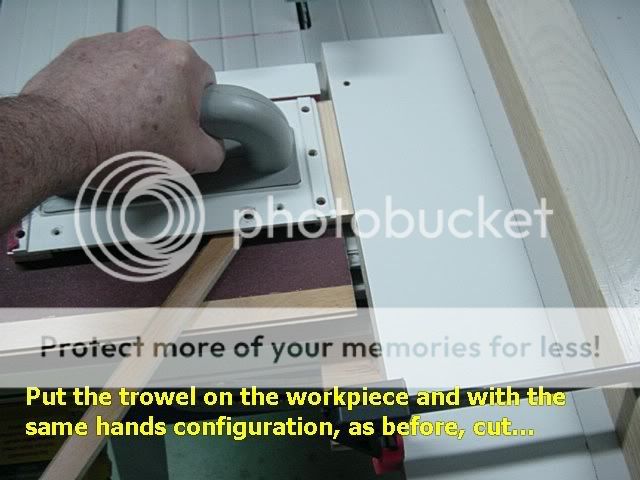

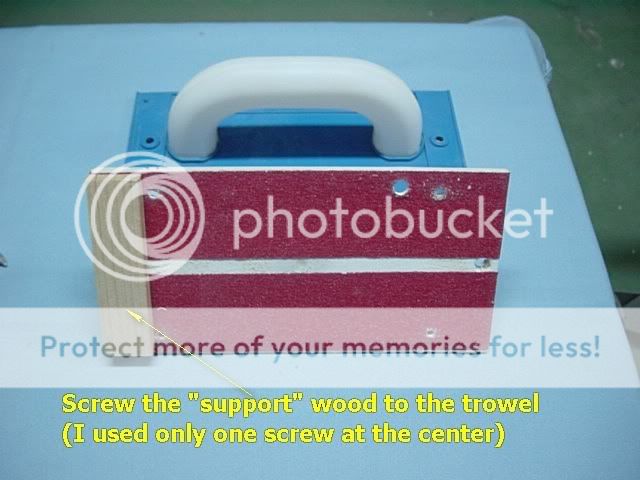

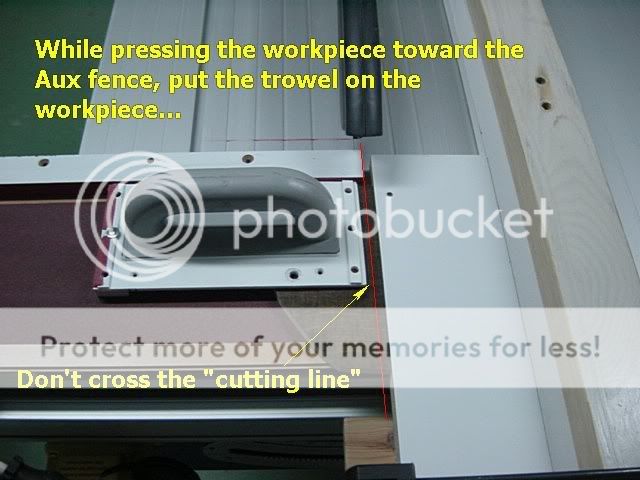

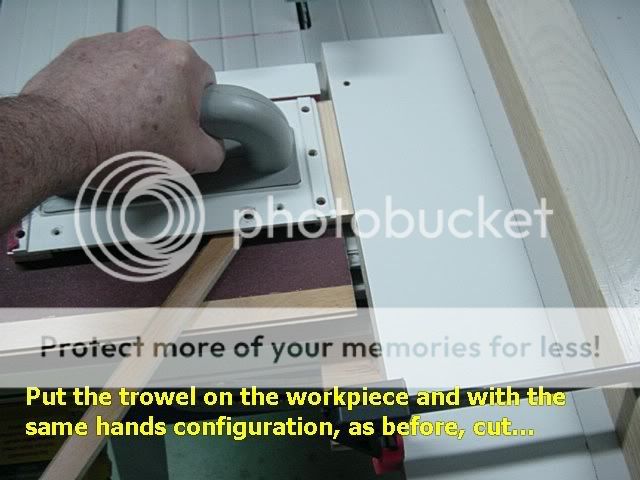

As you will see, I'm holding both hands on the trowel and that, doesn't leave too many hands or fingers to be used as a "Backer board" for the workpiece...saves a lot of money... :wink:

Regards

niki

I had to rip a few small pieces for some router table aid/fixture and I would like to share with you the method.

I'm using an Auxiliary fence clamped to the rip fence...now, when I'm saying Aux fence.... give me some good width say, 100~150 mm....you don't like to "drive" in congested areas, do you...

Before clamping the aux fence, give it a pass through the blade just to make sure that its parallel and consistent in width.

As you will see, I'm holding both hands on the trowel and that, doesn't leave too many hands or fingers to be used as a "Backer board" for the workpiece...saves a lot of money... :wink:

Regards

niki