SkinnyB

Established Member

I have been looking to add a cyclone unit to my extraction system for some time. Axminster's new cyclone range came up so I decided to go ahead with one of those.

Unboxing:

IMG_5943 by jamie skinner, on Flickr

IMG_5943 by jamie skinner, on Flickr

Height

IMG_5944 by jamie skinner, on Flickr

IMG_5944 by jamie skinner, on Flickr

View from the bottom - top (not mesh at the bottom just my table.)

IMG_5945 by jamie skinner, on Flickr

IMG_5945 by jamie skinner, on Flickr

I also got the bag attachment waste bin part.

IMG_5946 by jamie skinner, on Flickr

IMG_5946 by jamie skinner, on Flickr

IMG_5947 by jamie skinner, on Flickr

IMG_5947 by jamie skinner, on Flickr

IMG_5952 by jamie skinner, on Flickr

IMG_5952 by jamie skinner, on Flickr

IMG_5954 by jamie skinner, on Flickr

IMG_5954 by jamie skinner, on Flickr

IMG_5955 by jamie skinner, on Flickr

IMG_5955 by jamie skinner, on Flickr

IMG_5956 by jamie skinner, on Flickr

IMG_5956 by jamie skinner, on Flickr

I am wanting to use a dust bin I have to collect the shaving so I am modifying the unit to accept this bin.

First it to move one of the columns that hold the cyclone up so I can get the bin in. Using the lid as a template.

IMG_5950 by jamie skinner, on Flickr

IMG_5950 by jamie skinner, on Flickr

IMG_5957 by jamie skinner, on Flickr

IMG_5957 by jamie skinner, on Flickr

IMG_5958 by jamie skinner, on Flickr

IMG_5958 by jamie skinner, on Flickr

Marking and drilling new place for the column to allow for a bin to slide in.

IMG_5959 by jamie skinner, on Flickr

IMG_5959 by jamie skinner, on Flickr

IMG_5960 by jamie skinner, on Flickr

IMG_5960 by jamie skinner, on Flickr

Wider front opening.

IMG_5961 by jamie skinner, on Flickr

IMG_5961 by jamie skinner, on Flickr

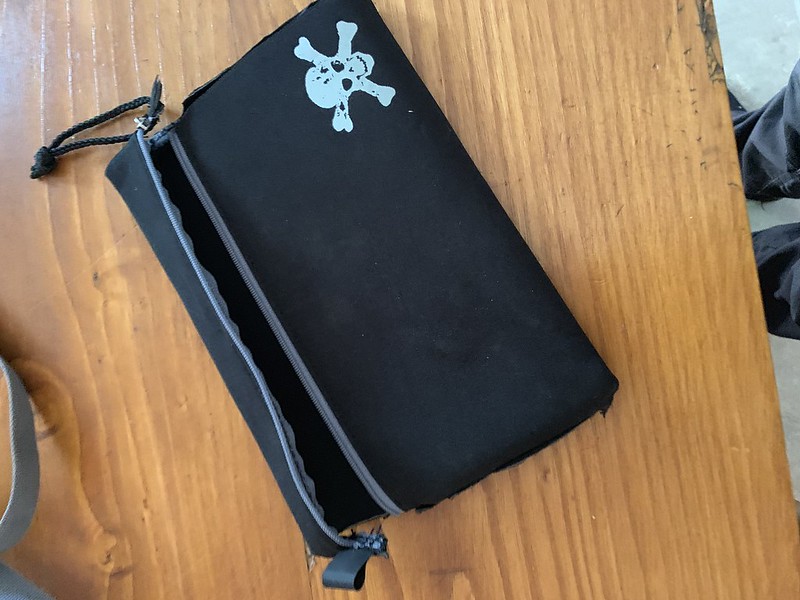

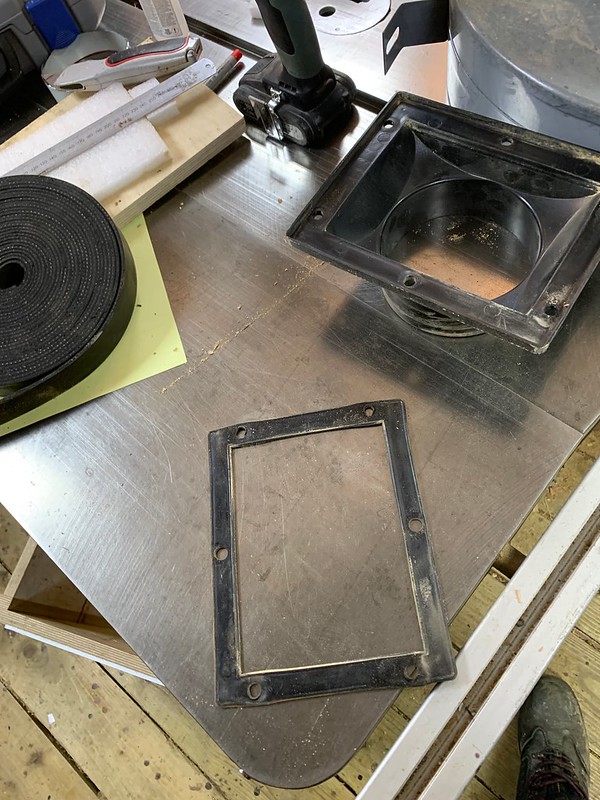

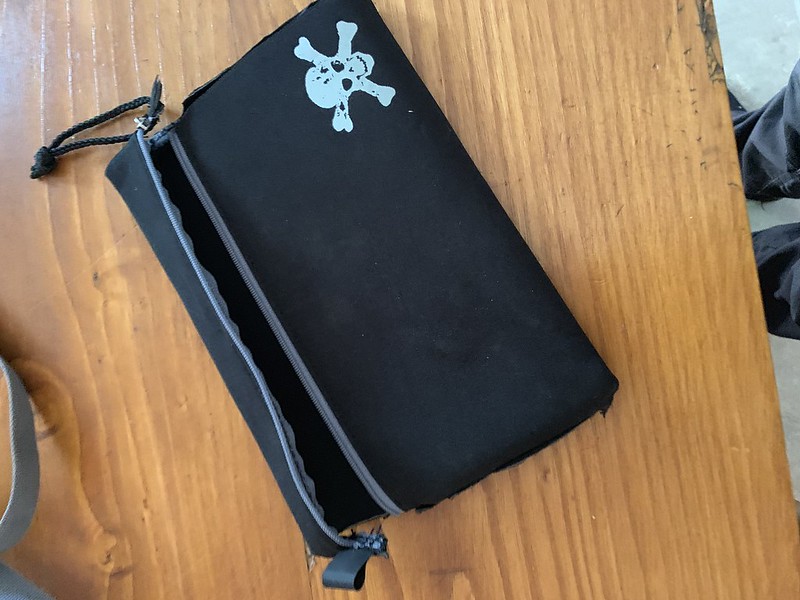

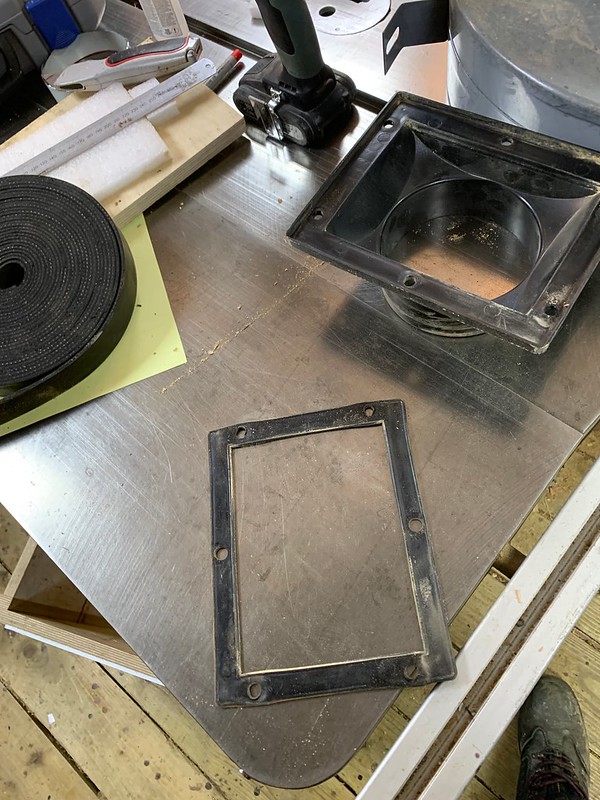

First issue.. Cyclone to base attachment. I was disappointed that this does not come with a gasket of sorts to seal the two parts.

IMG_5962 by jamie skinner, on Flickr

IMG_5962 by jamie skinner, on Flickr

old neoprene pencil case

IMG_5980 by jamie skinner, on Flickr

IMG_5980 by jamie skinner, on Flickr

IMG_5982 by jamie skinner, on Flickr

IMG_5982 by jamie skinner, on Flickr

IMG_5987 by jamie skinner, on Flickr

IMG_5987 by jamie skinner, on Flickr

Fixed!

IMG_5988 by jamie skinner, on Flickr

IMG_5988 by jamie skinner, on Flickr

Second issue... These should come with 125mm+ ports as standard as it is a lot easier to reduce than to enlarge them.

IMG_5967 by jamie skinner, on Flickr

IMG_5967 by jamie skinner, on Flickr

IMG_6001 by jamie skinner, on Flickr

IMG_6001 by jamie skinner, on Flickr

Cutting my blower intake. Action Shot!

IMG_5970 by jamie skinner, on Flickr

IMG_5970 by jamie skinner, on Flickr

Now fits

IMG_5977 by jamie skinner, on Flickr

IMG_5977 by jamie skinner, on Flickr

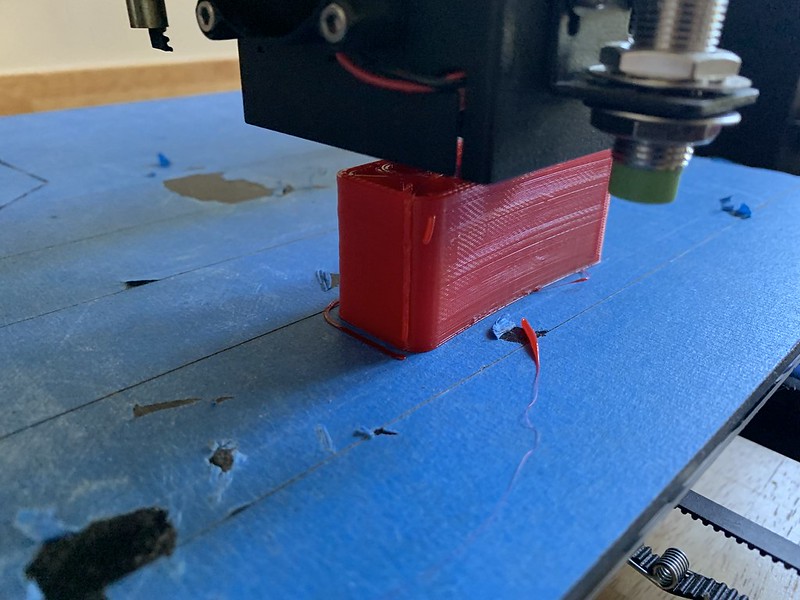

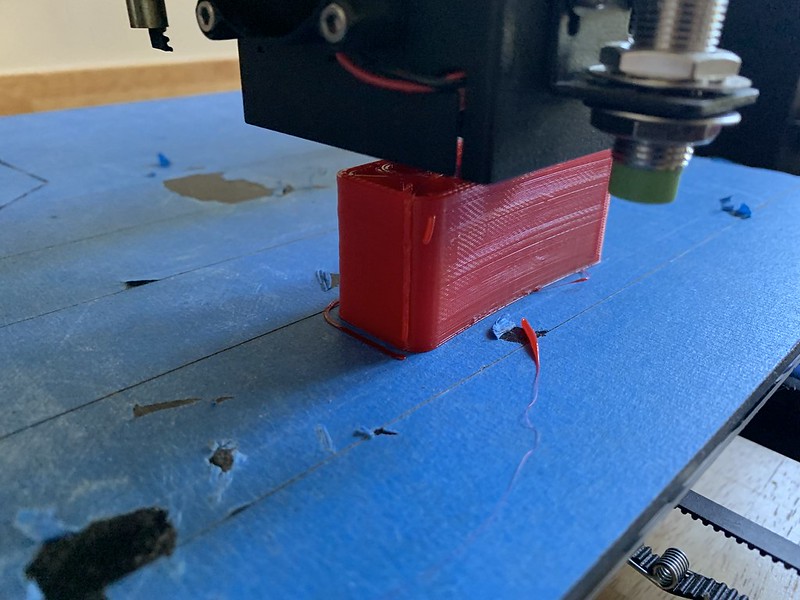

My issue.. Bin is too tall..

IMG_5964 by jamie skinner, on Flickr

IMG_5964 by jamie skinner, on Flickr

3D printing spacers

IMG_5978 by jamie skinner, on Flickr

IMG_5978 by jamie skinner, on Flickr

IMG_5983 by jamie skinner, on Flickr

IMG_5983 by jamie skinner, on Flickr

IMG_5984 by jamie skinner, on Flickr

IMG_5984 by jamie skinner, on Flickr

Third issue... Some of the fabricated metal joins have gaps in them. Easy fix

IMG_5990 by jamie skinner, on Flickr

IMG_5990 by jamie skinner, on Flickr

IMG_5991 by jamie skinner, on Flickr

IMG_5991 by jamie skinner, on Flickr

Fixed

IMG_5992 by jamie skinner, on Flickr

IMG_5992 by jamie skinner, on Flickr

Looking good so far

IMG_5993 by jamie skinner, on Flickr

IMG_5993 by jamie skinner, on Flickr

My blower issue. Bad seal around port. Fixed with new rubber and silicone.

IMG_6003 by jamie skinner, on Flickr

IMG_6003 by jamie skinner, on Flickr

IMG_6004 by jamie skinner, on Flickr

IMG_6004 by jamie skinner, on Flickr

IMG_6005 by jamie skinner, on Flickr

IMG_6005 by jamie skinner, on Flickr

Metal fabrication on my blower could do with some sealant.

IMG_6006 by jamie skinner, on Flickr

IMG_6006 by jamie skinner, on Flickr

IMG_6007 by jamie skinner, on Flickr

IMG_6007 by jamie skinner, on Flickr

Ready to mount the blower.

IMG_6008 by jamie skinner, on Flickr

IMG_6008 by jamie skinner, on Flickr

The exhaust port is facing the wrong way so I am moving it 90 degrees to face the right way

IMG_6009 by jamie skinner, on Flickr

IMG_6009 by jamie skinner, on Flickr

IMG_6011 by jamie skinner, on Flickr

IMG_6011 by jamie skinner, on Flickr

Placing two blocks to hold the blower the correct distance while I bolt to the wall.

IMG_6012 by jamie skinner, on Flickr

IMG_6012 by jamie skinner, on Flickr

Attached.

IMG_6013 by jamie skinner, on Flickr

IMG_6013 by jamie skinner, on Flickr

IMG_6014 by jamie skinner, on Flickr

IMG_6014 by jamie skinner, on Flickr

Turns out I didn't need to remove the grid in the end...

IMG_6016 by jamie skinner, on Flickr

IMG_6016 by jamie skinner, on Flickr

Bin is currently wedged from bottom. Looking to add clips later on the top to hold the bin to the unit so it seal better.

IMG_6017 by jamie skinner, on Flickr

IMG_6017 by jamie skinner, on Flickr

Adding seals. Ideally I need some wider seals but this is all I had on hand.

IMG_6022 by jamie skinner, on Flickr

IMG_6022 by jamie skinner, on Flickr

baby cyclone next to it.

IMG_6024 by jamie skinner, on Flickr

IMG_6024 by jamie skinner, on Flickr

My bin kept collapsing so I used some of the left over parts to brace the inside of the bin. These usually hold the bag open if using the bag that comes with the lower section.

IMG_6025 by jamie skinner, on Flickr

IMG_6025 by jamie skinner, on Flickr

Still a little more to do but overall pleased with the unit.

Improvements to the unit for me would be:

Larger dust posts on it. 125/150mm with plastic reducers offered.

Better seals. I found gaps in the cyclone using a torch around the base where I previously mentioned. Later I also found gaps around the "dust in" port which again used silicone to fix.

Gasket supplied for attaching bottom of cyclone.

I would buy again, and if these improvements were made, mainly the larger ports this will be great unit out of the box.

I am venting exhaust outside. I am planning on adding a filter unit to it for work in the winter.

Exhaust air looks very clean with minimal dust coming out when using my drum sander.

I believe my blower is 3hp. Ideally need 150mm posts on the cyclone for this size.

Currently I am just using a 100mm flex pipe to each machine as I use it. I will eventually replace with with 150mm spiral ducting which should offer better air flow than the long flex pipe.

Thanks for looking!

Unboxing:

IMG_5943 by jamie skinner, on Flickr

IMG_5943 by jamie skinner, on FlickrHeight

IMG_5944 by jamie skinner, on Flickr

IMG_5944 by jamie skinner, on FlickrView from the bottom - top (not mesh at the bottom just my table.)

IMG_5945 by jamie skinner, on Flickr

IMG_5945 by jamie skinner, on FlickrI also got the bag attachment waste bin part.

IMG_5946 by jamie skinner, on Flickr

IMG_5946 by jamie skinner, on Flickr IMG_5947 by jamie skinner, on Flickr

IMG_5947 by jamie skinner, on Flickr IMG_5952 by jamie skinner, on Flickr

IMG_5952 by jamie skinner, on Flickr IMG_5954 by jamie skinner, on Flickr

IMG_5954 by jamie skinner, on Flickr IMG_5955 by jamie skinner, on Flickr

IMG_5955 by jamie skinner, on Flickr IMG_5956 by jamie skinner, on Flickr

IMG_5956 by jamie skinner, on FlickrI am wanting to use a dust bin I have to collect the shaving so I am modifying the unit to accept this bin.

First it to move one of the columns that hold the cyclone up so I can get the bin in. Using the lid as a template.

IMG_5950 by jamie skinner, on Flickr

IMG_5950 by jamie skinner, on Flickr IMG_5957 by jamie skinner, on Flickr

IMG_5957 by jamie skinner, on Flickr IMG_5958 by jamie skinner, on Flickr

IMG_5958 by jamie skinner, on FlickrMarking and drilling new place for the column to allow for a bin to slide in.

IMG_5959 by jamie skinner, on Flickr

IMG_5959 by jamie skinner, on Flickr IMG_5960 by jamie skinner, on Flickr

IMG_5960 by jamie skinner, on FlickrWider front opening.

IMG_5961 by jamie skinner, on Flickr

IMG_5961 by jamie skinner, on FlickrFirst issue.. Cyclone to base attachment. I was disappointed that this does not come with a gasket of sorts to seal the two parts.

IMG_5962 by jamie skinner, on Flickr

IMG_5962 by jamie skinner, on Flickrold neoprene pencil case

IMG_5980 by jamie skinner, on Flickr

IMG_5980 by jamie skinner, on Flickr IMG_5982 by jamie skinner, on Flickr

IMG_5982 by jamie skinner, on Flickr IMG_5987 by jamie skinner, on Flickr

IMG_5987 by jamie skinner, on FlickrFixed!

IMG_5988 by jamie skinner, on Flickr

IMG_5988 by jamie skinner, on FlickrSecond issue... These should come with 125mm+ ports as standard as it is a lot easier to reduce than to enlarge them.

IMG_5967 by jamie skinner, on Flickr

IMG_5967 by jamie skinner, on Flickr IMG_6001 by jamie skinner, on Flickr

IMG_6001 by jamie skinner, on FlickrCutting my blower intake. Action Shot!

IMG_5970 by jamie skinner, on Flickr

IMG_5970 by jamie skinner, on FlickrNow fits

IMG_5977 by jamie skinner, on Flickr

IMG_5977 by jamie skinner, on FlickrMy issue.. Bin is too tall..

IMG_5964 by jamie skinner, on Flickr

IMG_5964 by jamie skinner, on Flickr3D printing spacers

IMG_5978 by jamie skinner, on Flickr

IMG_5978 by jamie skinner, on Flickr IMG_5983 by jamie skinner, on Flickr

IMG_5983 by jamie skinner, on Flickr IMG_5984 by jamie skinner, on Flickr

IMG_5984 by jamie skinner, on FlickrThird issue... Some of the fabricated metal joins have gaps in them. Easy fix

IMG_5990 by jamie skinner, on Flickr

IMG_5990 by jamie skinner, on Flickr IMG_5991 by jamie skinner, on Flickr

IMG_5991 by jamie skinner, on FlickrFixed

IMG_5992 by jamie skinner, on Flickr

IMG_5992 by jamie skinner, on FlickrLooking good so far

IMG_5993 by jamie skinner, on Flickr

IMG_5993 by jamie skinner, on FlickrMy blower issue. Bad seal around port. Fixed with new rubber and silicone.

IMG_6003 by jamie skinner, on Flickr

IMG_6003 by jamie skinner, on Flickr IMG_6004 by jamie skinner, on Flickr

IMG_6004 by jamie skinner, on Flickr IMG_6005 by jamie skinner, on Flickr

IMG_6005 by jamie skinner, on FlickrMetal fabrication on my blower could do with some sealant.

IMG_6006 by jamie skinner, on Flickr

IMG_6006 by jamie skinner, on Flickr IMG_6007 by jamie skinner, on Flickr

IMG_6007 by jamie skinner, on FlickrReady to mount the blower.

IMG_6008 by jamie skinner, on Flickr

IMG_6008 by jamie skinner, on FlickrThe exhaust port is facing the wrong way so I am moving it 90 degrees to face the right way

IMG_6009 by jamie skinner, on Flickr

IMG_6009 by jamie skinner, on Flickr IMG_6011 by jamie skinner, on Flickr

IMG_6011 by jamie skinner, on FlickrPlacing two blocks to hold the blower the correct distance while I bolt to the wall.

IMG_6012 by jamie skinner, on Flickr

IMG_6012 by jamie skinner, on FlickrAttached.

IMG_6013 by jamie skinner, on Flickr

IMG_6013 by jamie skinner, on Flickr IMG_6014 by jamie skinner, on Flickr

IMG_6014 by jamie skinner, on FlickrTurns out I didn't need to remove the grid in the end...

IMG_6016 by jamie skinner, on Flickr

IMG_6016 by jamie skinner, on FlickrBin is currently wedged from bottom. Looking to add clips later on the top to hold the bin to the unit so it seal better.

IMG_6017 by jamie skinner, on Flickr

IMG_6017 by jamie skinner, on FlickrAdding seals. Ideally I need some wider seals but this is all I had on hand.

IMG_6022 by jamie skinner, on Flickr

IMG_6022 by jamie skinner, on Flickrbaby cyclone next to it.

IMG_6024 by jamie skinner, on Flickr

IMG_6024 by jamie skinner, on FlickrMy bin kept collapsing so I used some of the left over parts to brace the inside of the bin. These usually hold the bag open if using the bag that comes with the lower section.

IMG_6025 by jamie skinner, on Flickr

IMG_6025 by jamie skinner, on FlickrStill a little more to do but overall pleased with the unit.

Improvements to the unit for me would be:

Larger dust posts on it. 125/150mm with plastic reducers offered.

Better seals. I found gaps in the cyclone using a torch around the base where I previously mentioned. Later I also found gaps around the "dust in" port which again used silicone to fix.

Gasket supplied for attaching bottom of cyclone.

I would buy again, and if these improvements were made, mainly the larger ports this will be great unit out of the box.

I am venting exhaust outside. I am planning on adding a filter unit to it for work in the winter.

Exhaust air looks very clean with minimal dust coming out when using my drum sander.

I believe my blower is 3hp. Ideally need 150mm posts on the cyclone for this size.

Currently I am just using a 100mm flex pipe to each machine as I use it. I will eventually replace with with 150mm spiral ducting which should offer better air flow than the long flex pipe.

Thanks for looking!