devonwoody

Established Member

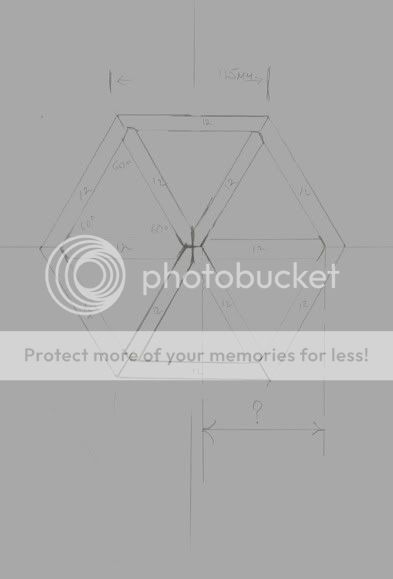

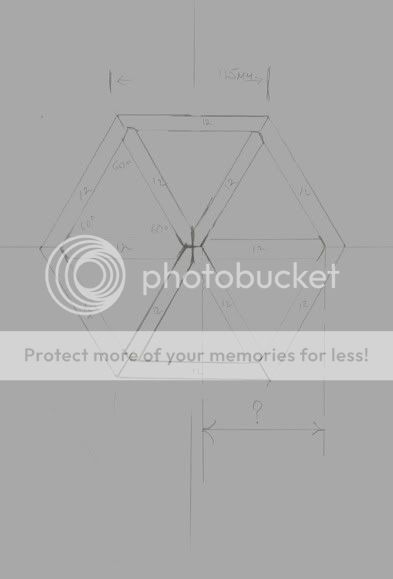

Can someone please supply the missing measurement?

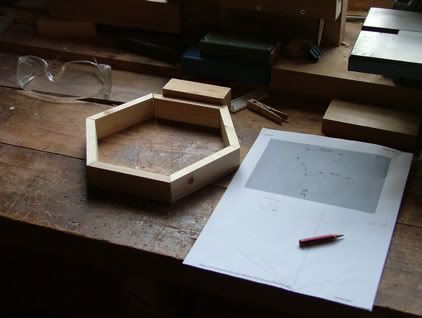

Got a new box in mind.

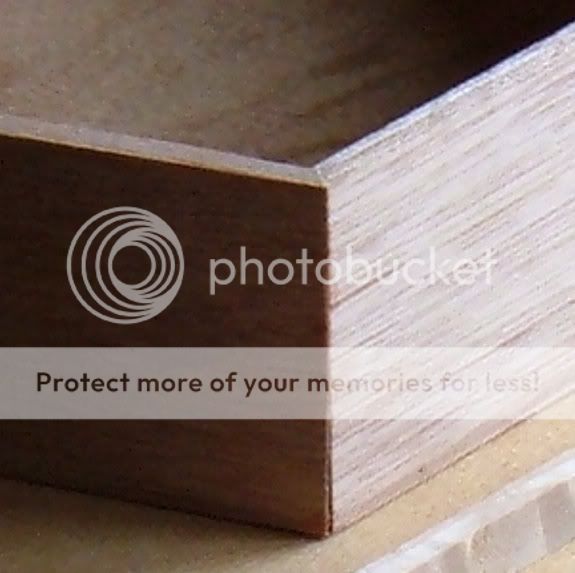

timber thickness 12mm and width is to be 115mm unless this measurement produces an unpleasant missing measure and then it can be changed.

Got a new box in mind.

timber thickness 12mm and width is to be 115mm unless this measurement produces an unpleasant missing measure and then it can be changed.