Chems

Established Member

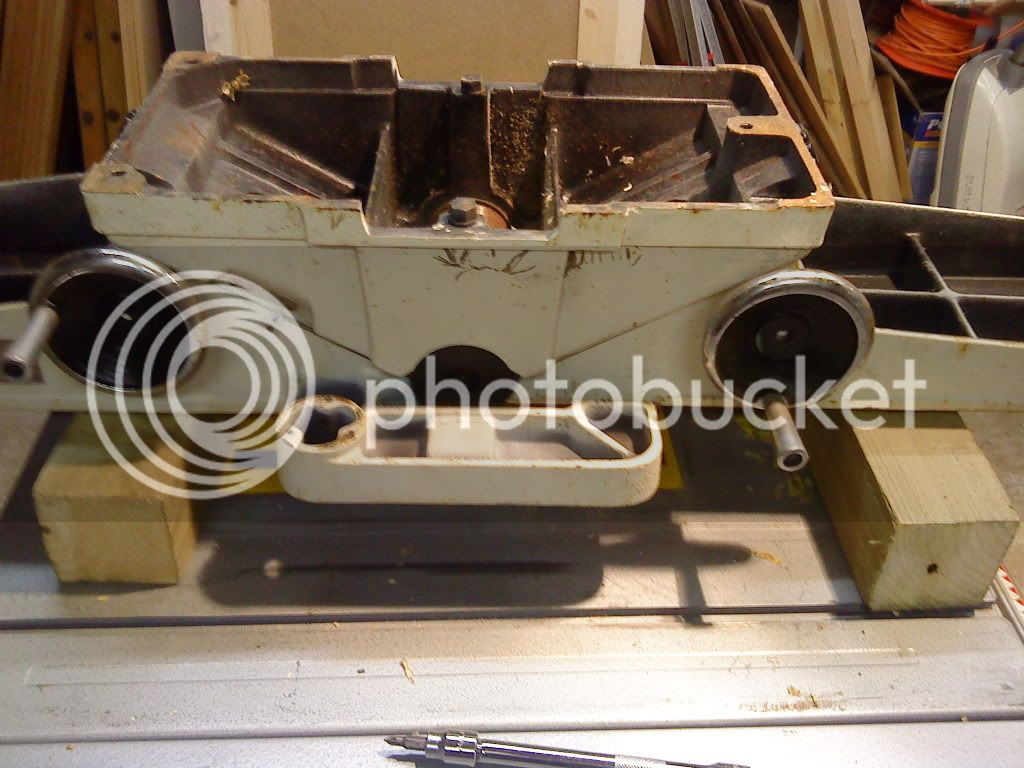

I have a cast iron planer and it has seen better days. The surface is heavily rusted (which comes off easily) but there is some pitting around the tables. I've been working on it with all sorts of kits, ROS, and diamond stones, whetstones everything I can think of to remove the material.

Whats the best suggestion for removing material from such a large area? I'm thinking it may be best to buy a Belt sanders and just work through the grades?

Whats the best suggestion for removing material from such a large area? I'm thinking it may be best to buy a Belt sanders and just work through the grades?