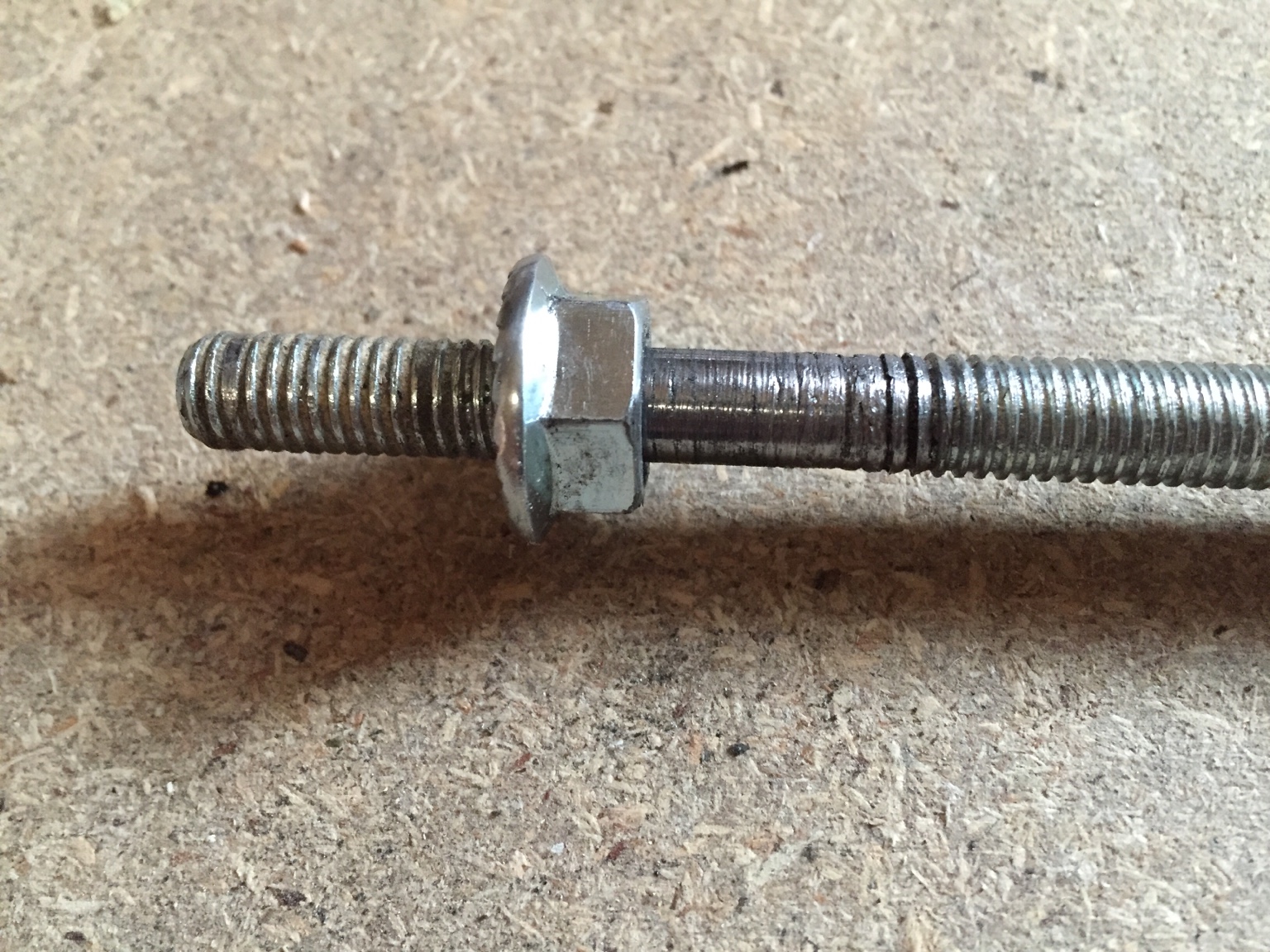

I've been playing around with this all afternoon, trying to figure out why it won't tension and it turns out the thread appears to have stripped itself?

Can't loosen the top handle fitting to just replace with a bit of threaded bar either. Would this normally be a simple fix, I can't believe it's happened if I'm honest.

Sent from my iPhone using Tapatalk

Can't loosen the top handle fitting to just replace with a bit of threaded bar either. Would this normally be a simple fix, I can't believe it's happened if I'm honest.

Sent from my iPhone using Tapatalk